How Does a Salt Water Chlorine Generator Create Chlorine in a Pool?

The SWG cell consists of titanium metal plates coated with a layer of mixed metal oxide catalyst (ruthenium monoxide and iridium). 18-36 volts DC electrical current is passed between the plates. The electronic control circuitry controls the voltage and amperage in the cell. Some systems keep the voltage constant and vary the amperage; other systems vary the voltage and keep constant amperage:[1]

- Pentair tries to keep the current constant by changing the voltage

- Jandy tries to keep the current constant by changing the voltage

- Hayward keeps the voltage constant, and the current varies based on the water temperature and the salinity.

Most US-designed SWGs use a percentage-based on/off cycle, while some Australian designed SWG models vary the power rather than the on/off times. SWG Generation Cycle Times explains more about how the SWG % and cycle times work for various model SWGs.

We recommend that your SWG capacity be at least 2X your pool volume. Published SWG capacity is based on the pump and SWG running 24/7 at 100%, which you may not want to do. It is best to have excess chlorine generation capacity.

SWG Price Changes

The coverage of the titanium plates is about 80/20 ruthenium/iridium oxide. When the price of the ruthenium part increases 400%, it's obvious that the price of the entire cell must increase. The plates for a T-15 cell cost $200 in 2018, whereas in 2017, they were only about $50-60. Then there is the housing, electronics, cord, and all the other fixed expenses before companies even get to their marketing expenses and overhead.[2]

Since there are only a couple of suppliers for coating plates, there is no room for price negotiations. Cell suppliers will simply pass the costs on to customers.

As of February 1, 2021, the price of Ruthenium has gone up 20% in the past 15 days, and the cost of Iridium has gone up 200% in the past 60 days. You must remember that Ru's price increased by 200% in 2019-2020. Since the coating on salt cell plates is about 6:1 Ruthenium/Iridium, this translates into MUCH higher prices for a salt cell in 2021.[3]

The recent Ir price increase is explained as supplies from mines in South Africa having essentially been shut off due to a variant COVID strain originating there.

SWG Economic Analysis

SWGs are often sold as hands-off to people who never learned their systems or chemistry, and those are the disasters you hear about.

Figuring out your ROI is pretty simple. For 26k gallons, each gallon of 10% chlorine nets you 3.84 FC. Here is your FC cost for the gallon prices you will likely see this season.[4]

- $5 gallon = $1.30 per FC

- $6 gallon = $1.56 per FC

- $7 gallon = $1.82 per FC

Narrow down your SWG choices and find its production of chlorine per 24 hours in PoolMath. A 10k-hour lifespan unit equals 417 days of production. Multiply the daily production by 417 to get your total lifespan FC produced. (In perfect conditions).

If applicable, take the cost of the SWG, controller, and installation costs and divide that by the lifespan FC for your cost per FC.

So, let's take a Pentair IC60 system that is going for $1600 today. It produces 9.2 FC daily in 26k gallons, or 3836 lifetime FC.

A $1600 system = $0.42 per FC, which is about 1/3 the cost of the cheapest gallon of bleach for sale right now. In theory, over its lifespan, the unit will be three times cheaper than LC for you.

If you don't DIY, installation costs will take away some savings. If installation doubles the cost to $3200, you'll save some on the first cell, but the future cells will be the big payback.

The $569 controller usually lasts three cells, so the following two replacements only need the $1100 cell, basically covering your installation costs, and if you DIY'd it, the replacement units will pay off

$1100 unit = $0.28 per FC.

In summary, many would pay 3X the liquid chlorine price for the SWG's convenience. That 'payback' is priceless. With a SWG, you spend less time on FC monitoring/adjusting from June to mid-November. That includes getting the kit out, getting a water sample, and putting the kit away. Your FC can stay at a high target or above, and the thought of algae never enters your mind. *And* it can save you 2 or 3 times what the LC would have cost, not including time and effort.

Chemistry behind a SWG

Salt is sodium(NA) and chloride(CL). When salt dissolves in pool water, the Na and Cl break apart.

The chloride ions lose an electron at the cell plate, forming chlorine gas Cl2.

Electrolysis removes an electron from the chloride and puts an electron on the hydrogen ions that make contact with the opposite side of the cell plates.

So, a chloride ion is on one side of the plate, and a hydrogen ion is on the other side of the plate, and an electron moves from the chloride ion through the plate and onto the hydrogen ion.[5]

The electrolytic cell generates chlorine gas at the anode and hydrogen gas at the cathode. The chlorine gas rapidly dissolves into the water and hydrates to form a mixture of HOCl/OCl, which is pH dependent, and the hydrogen gas bubbles out of the return (hydrogen is not soluble in water).[6]

SWG Cell Should Not be Powered When Pump is Off

Most SWG manufacturers, including Pentair IntelliChlor and iChlor, Hayward Aquarite, and Jandy Aquapure, recommend that the SWG power be OFF when the pump is off. Some manufacturers do not, and TFP recommends that even for those, the SWG power should be OFF when the pump is off.

Running your pump 24/7 eliminates the need to switch SWG power separately. You must remember to turn the SWG off when you turn the pump off for maintenance. In day-to-day operation, the pump and SWG can always be on.

Most SWGs use a flow switch that can fail. A few, like the Jandy TruClear, use a gas trap for flow sensing. The flow switch is a secondary safety mechanism. There should be a primary means for the cell not to be powered when the pump is off and there is no water flow. This can be with pool automation equipment, relays in the pump, a mechanical timer, or a current sensing relay controlling SWG power.

If the flow switch fails and the cell is powered while the pump is off, the cell can generate chlorine, and hydrogen gas can accumulate in the cell and explode. Here are some reports of cell explosions:

SWG Automation Power Control

Automation panels will turn the SWG power on and off when the filter pump is turned on and off.

For Pentair EasyTouch/IntelliTouch/IntelliCenter and Jandy Aqualink automation to control the SWG power with the filter pump the SWG power needs to be wired to the filter pump relay.

A SWG can be connected to the Pentair IntelliConnect relay. You tell the system through the Pentair POOL app that an SWG is connected, and the relay will be coordinated with the pump.

Hayward OmniLogic, ProLogic, AquaLogic, OmniPL, and Omni Hub all have built-in SWG controllers. If the cell is plugged into the board, it will be powered with the filter pump. If you are connecting a standalone Aquarite SWG]] panel or other SWG, then the power should be connected to the filter pump relay.

SWG Pump IO-Board Relay Control

Pentair Intelliflo3/IntelliPro3 and various Jandy pumps can include an IO Board with relays that control SWG power. You configure the pump so that the relay is powered when the pump is running.

If you upgrade from a single-speed pump to a VS pump and do not have automation, this is a good way to coordinate the pump and SWG runtime.

SWG Power Timer Control

With a single-speed pump, the pump and SWG can both be controlled by a single Intermatic timer.

A Variable Speed pump (VS) should have continuous power and not be connected to a timer. The pump runtime should be controlled by its internal control panel and clock. A separate mechanical timer can control the SWG. Care must then be taken for the SWG timer to turn on 15 minutes after the pump begins running and SWG power off before the pump turns off. This can become a problem when house power is lost, and the pump retains the proper time while the mechanical timer does not.

SWG Current Sensing Relay Control

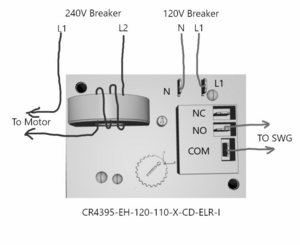

If you are proficient in electrical wiring, you can assemble the parts to control SWG power through a current sensing relay that turns on the SWG power when it senses that the pump's power is on.

A search will find various threads on it, including these:

- My wiring diagram for current sensing relay

- Current Sensing Relay for SWG with Variable Speed pump

- current sensing relay help

SWG RS-485 Pump Control

A few pump and SWG combinations talk directly to each other through RS-485 without an automation panel.

Pentair Smart Sense Flow Detection requires an iChlor SWG and an Intelliflo pump. SmartSense will not work with SuperFlo VS, VST, or other Pentair VS pumps.

Jandy TruClear chlorination system with Firmware Revision F or later can monitor the state of the Jandy Variable Speed Pump so that the TruClear does not operate if the Jandy Variable Speed Pump is not running.

What Speed Should a VS Pump be Run with a SWG?

You can run a VS pump as slowly as possible to keep the SWG happy and skimming effectively. Any RPM is good enough for circulation, but both the SWG and skimming have minimums, which can only be determined easily by trial and error.[7]

Start with 1000 RPM. If the SWG does not alarm and the water travels over the weir door in the skimmer (instead of around the sides), then that is probably a good starting point. Anything less than 1000 RPM doesn't save much energy. Only raise RPM if the SWG alarms and/or skimming are ineffective.

Does a SWG Create Bubbles?

A SWG cell makes chlorine gas and hydrogen gas. The chlorine gas dissolves quickly, and you won't usually see any coming out of the returns. Hydrogen gas does not dissolve very well. The gas coming from returns is hydrogen.

The only time you can see chlorine gas is when you have a clear cell and can see the chlorine gas and hydrogen gas being generated at the plates.

Does Running a SWG at 100% Effect Cell Life?

Chlorine generators for pools operate far from ideal conditions so the more stress you put on the plates by running them at a 100% duty cycle, the worse off the catalytic coating is going to fare.[8]

Two main factors affect the electrolysis of chlorine gas - current density distribution across the plate and cell AND mineralization of the plate surface. In a bipolar electrolysis cell, the current “crowds” mainly at the plate's edges and any “hot spots” on the surface. Current crowding is a problem in any electrolytic setup. What it typically does is cause the catalytic coating to degrade along edges first and anywhere there are hot spots. At these high current density areas, you also get greater precipitation of minerals, mainly calcium, from pool water. The calcium mineralization is non-conductive for the most part, so it also exacerbates the irregular current distribution.

To abate some of these problems, cells are designed with three electrodes where the outer plates are often ground, and the center plate is charged. The plates are also set into non-conductive dividers to help keep the current from flowing around the edges where the electric fields are the least uniform. One then reverses a periodic current to alternate which side of the plates are anodes and which are cathodes. This helps distribute the inherent damage across all plates evenly and reduces the scale formed on any side. The plate spacing and voltages used are set to minimize as much current variation as possible, but there will always be a current bulge due to a flowing electrolyte.

The belief is that the more you can let a cell “rest” by keeping the output % low, the more chance you give for mineralization to be redissolved into solution. The more you drive the plate with no OFF time, the more those plates sit in a high pH, highly oxidative solution. That chemistry can cause the precipitation of scale and the dissolution of ruthenium metal from the plate.

The Pourbaix diagrams for the stability of ruthenium species in chloride solutions get very complex, with multiple soluble species being possible. Ruthenium is a weird metal in that some of its oxides are insoluble, while other oxides can exist as a gas phase. Ruthenium hydroxides and chlorides are very soluble in water. Its complex behavior is what gives rise to its usefulness as a catalyst.

No one is saying an SWG owner can’t run a cell at 100% when it’s necessary. But it’s far better to design a pool system with adequate SWG cell capacity where running 100% is unnecessary daily. You can drive the SWG cell as hard as you can and hope for the best, but you will not get your published lifetimes on these cells.

How to Clean a SWG Cell

You should only clean a SWG cell with visible scale on the plates.

Try cleaning with the process that will do the least damage to the rare metal plates, and then move to more aggressive methods if necessary.

Cleaning a SWG cell with Water

First, try and use strong blasts of water to remove the scale. One member found success using a Waterpik.

Cleaning a SWG cell by Scraping Plates

To remove the scale, you can scrape the plates with a stick, like a Popsicle stick or a paint stirrer free from paint stores.

Zip ties or Drain Clog Remover Snake[9] have been used.

Cleaning a SWG cell with Vinegar Acetic Acid

If the scale is stubborn, use cleaning vinegar (6% acetic acid … available in Home Depot). It’s milder than Muriatic Acid and won’t damage the ruthenium surface. Highly concentrated mineral acids are not good for the transition metal catalysts.

If you have 30% vinegar, then a 4:1 ratio of water to vinegar will take you down to 6% concentration, which is what “cleaning” vinegar is. 6% is MORE than enough to remove any carbonate scale.

Cleaning a SWG cell with Citric Acid

On a molar basis, citric acid will be “stronger” than acetic or ascorbic acid. So it will produce a solution with lower pH due to more acid protons (H+) being released. This is why your perception is that it works better on scale than vinegar does.[10]

All acids will remove a small amount of material from the surface because ruthenium oxide is unstable in acidic conditions. Ruthenium metal itself is highly reactive to air, forming ruthenium oxide. In water, a pure ruthenium metal surface will slowly oxidize based on the amount of dissolved oxygen in the water and oxidation formed by hydrolysis. So, if you leave a chunk of ruthenium in highly acidic water for a long period of time, it will dissolve.

The key to cleaning the calcium scale off the plates is to use an acid strong enough to destabilize the carbonate anion (force carbonate to become CO2) and remove the calcium without the acid, also etching the ruthenium metal. The conjugate base of the acid matters as well. Chlorides and sulfates do increase the likelihood of reforming ruthenium oxides quickly enough at the ruthenium metal surface such that hydrochloric acid and sulfuric acid would be poor choices. Ascorbate ions from ascorbic acid tend to be anti-oxidants and will less likely increase the repassivation of the metal surface. Acetic acid creates acetate ions which also weakly interact with ruthenium. As far as citrate goes (the conjugate base of citric acid), I'm not entirely certain, as I would have to search the literature for it. I guess it will be more aggressive towards ruthenium than ascorbic acid or acetic acid but much less aggressive than muriatic acid. Citrate acts as a chelating agent to many transition metals like iron and cobalt, so I would expect ruthenium to complex pretty readily with citrate, given the many different stable oxidation states that a ruthenium atom can attain. Ascorbates and acetates are weaker chelating agents.

Vinegar can be just as effective but if you don't happen to have vinegar lying around, and the big bag of citric acid is just sitting there screaming to be used, then you can use it without much harm. There's no need to make highly concentrated solutions. A few % citric acid in distilled water will soften or remove calcium scale. Then just hit it with a garden hose spray to flush it out.

Cleaning a SWG cell with Muriatic Acid

Cleaning an SWG cell with a 10:1 diluted solution of muriatic acid will remove some of the rare earth coatings from the plates and reduce the cell's life with every cleaning.

History of SWG

Diamond Shamrock Corp. created the Lectranator in 1976.[11] A patent was filed for on 11-11-1976 and granted on 7-11-1978 - DOCUMENT ID: US 4100052 A - APPLICATION NO: 05/740870. The patent description was:

Disclosed is an electrolytic cell for the generation of low cost halogen biocidally active agent from an aqueous solution having a low halogen salt content for use in the treatment of sewage or other liquid effluents, especially those of fresh water swimming pools or fresh water cooling towers.

The electrolytic cell is used in line with pumps generally associated with the distribution of waters for swimming pools or cooling towers.

The present invention generally relates to an electrolytic cell for the generation of low cost halogen biocidally active agent for the treatment of a sewage or other liquid effluents especially those waters of a fresh water swimming pool or cooling towers. More particularly, the present disclosure relates to an improved electrolytic cell having a bipolar configuration which is used in line with the pumps generally associated with the distribution of waters in swimming pools or cooling towers or other liquid effluents for the generation of chlorine from affluent containing low levels of chloride.

This employs an enclosure connected in line with the liquid distribution system of the facility containing a series of parallel planar plates to be utilized as electrodes arranged such that the effluent flows through the parallel planar matrix of plates and is treated thereby with the chlorine being electrolytically produced from within the confines of the electrolytic cell.

The Lectranator has been in production since 1978 (16 years before the AquaRite).

Lectranator Corp was sold to Olin and then to Team Horner in May 1992 and this became the AutoPilot SWG.

Goldline Controls®, began as Independent Energy, Inc., a company founded in 1975. In 1994, the company began producing Aqua Rite® salt chlorinators for swimming pools.

Hayward® Industries, Inc. acquired Goldline Controls® in August 2004.

- ↑ https://www.troublefreepool.com/threads/swcg-controllers.243464/post-2133838

- ↑ https://www.troublefreepool.com/threads/salt-cell-price-increases.171363/post-1511996

- ↑ https://www.troublefreepool.com/threads/diferent-circupool-models-output.200582/post-1958842

- ↑ https://www.troublefreepool.com/threads/considering-swg-generator-but-i-have-concerns.268595/post-2353072

- ↑ https://www.troublefreepool.com/threads/low-salt-swg.193378/post-1708031

- ↑ https://www.troublefreepool.com/threads/hypochlorous-acid.205081/post-1805763

- ↑ https://www.troublefreepool.com/threads/optimal-pump-rpm.287084/post-2517287

- ↑ https://www.troublefreepool.com/threads/running-a-swg-at-100-and-cell-life.257582/post-2251798

- ↑ https://www.troublefreepool.com/threads/household-drain-cleaning-tool-to-clean-swg-cell-plates.289835/post-2543693

- ↑ https://www.troublefreepool.com/threads/citric-acid-suitability-for-swg-cleaning.262647/post-2297978

- ↑ https://www.troublefreepool.com/threads/help-in-identifying-my-set-up.266319/post-2330456