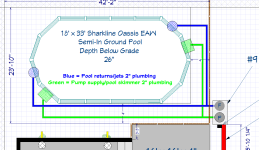

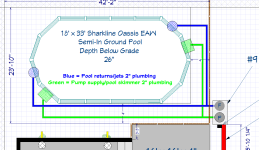

18 x 33 x 56" Semi-In Ground NJ

- By Brian.O1484

- Above Ground Pools

- 157 Replies

Alrighty so I didn't quite make my plumbing list last night since I was fooling around with layouts on the plumbing. Originally, I had everything at the back of the yard but then I realized I would have to do all of that after pool construction since the gate (in between the black lines) is getting removed to allow access for excavation and so on. A solid fence is being built in place of the gates, pickets will be added as well to eliminate any footholds on the fence, and it is already above the minimum height of 42".

F/P are the Filter and pump assemblies, The equipment pad is 3' x 5' in the plan but I think I may go 3x6 and will more than likely make a hinged roof off the fence to keep the sun off the equipment; more on that when I get to it .

.

Anyway, plumbing thoughts; as usual, add anything you think would be beneficial to do now

*The red and yellow are electrical before anyone asks lol, outlets at the patio will probably come next year when we do everything else.

F/P are the Filter and pump assemblies, The equipment pad is 3' x 5' in the plan but I think I may go 3x6 and will more than likely make a hinged roof off the fence to keep the sun off the equipment; more on that when I get to it

Anyway, plumbing thoughts; as usual, add anything you think would be beneficial to do now

- All 2" plumbing, the skimmers say 1.5" but I believe you can get a 2" coupler on the outside of them, will verify the skimmer/return models with the pool peeps

- Unions at the pump and filter intake/discharge

- 3-way valves after the unions

- 2" tee's going to returns and skimmers

- 4- flow valves after the tee's to allow for adjustment

- Runs to returns/skimmers 12" below grade

- Unions

- Shutoff valves below returns and skimmers

- I may put and extra Tee and valve in the "top" return line (looking at the picture) for a fountain/water feature to help cool in summer

- I may also put in a bypass for a WOOD FIRED HEATER down the line, I am holding my ground on not getting an electric or gas heater

my PSE&GH bills are high enough and I'm sure they will be more with just the pump lmao.

my PSE&GH bills are high enough and I'm sure they will be more with just the pump lmao.

*The red and yellow are electrical before anyone asks lol, outlets at the patio will probably come next year when we do everything else.