Hayward S200 sand filter. How do I install the Bottom Drain Screen?

- By krick

- Pumps, Filters, and Plumbing

- 0 Replies

I have an older Hayward S200 sand filter. I'm replacing the bottom half of the tank because of leaks from some hairline cracks where the bulkhead fittings pass through.

I can't figure out how the bottom drain screen attaches to the new tank. On my old tank, it seems like it was glued in but that doesn't seem right.

Here's the parts in question:

www.hydropool.com

www.hydropool.com

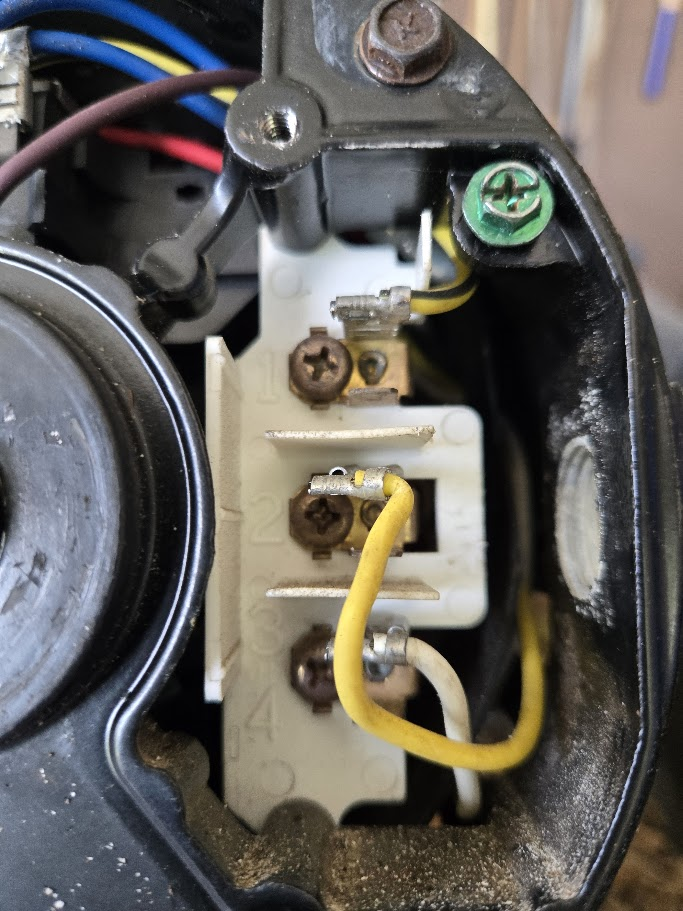

If anyone needs pictures of inside of the tank, let me know and I'll update this post.

I can't figure out how the bottom drain screen attaches to the new tank. On my old tank, it seems like it was glued in but that doesn't seem right.

Here's the parts in question:

- SX200AA1T - FILTER TANK W/DRAIN -TAUPE-

- SX200H - BOTTOM DRAIN SCREEN

Drain Screen, Hayward S160T/S220

Hayward Pool Products Drain Screen, Hayward S160T/S220 - Item 31-150-1206. Save on this and other Hayward Pool Products replacement pool & spa parts from Hydropool.com.

If anyone needs pictures of inside of the tank, let me know and I'll update this post.