You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Filters

Show only:

WATERWAY SUPREME (or HAYWARD POWERFLO MATRIX) PUMP MOTOR REPLACEMENT

- By Texas Splash

- Pumps, Filters, and Plumbing

- 1 Replies

Here is my experience for changing the motor on a Waterway Supreme pump. The Hayward Powerflo Matrix pump is basically the same. In fact, that’s the item used in this InyoPools video example:

Login to view embedded media

NOTE: If you are swapping the entire pump assembly from Waterway to Hayward Powerflo or visa-versa, know that while both have 1.5 inch “Internal” port threads, the Wateway’s “external” threads differ from the Hayward. So if your plumbing is connected to the pump by the external union nuts, be prepared to change the fittings for external threads or convert to the 1.5 inch internal port threads.

Waterway Supreme parts illustration: POOL PUMPS & PARTS : SUPREME PUMP PARTS - Waterway Parts Pool Supplies

Hayward Powerflo Matrix parts illustration: Hayward PowerFlo Matrix Pump Parts - INYOPools.com

My factory-installed pump & motor info:

Waterway Supreme Pump P/N: PS2200-6

Waterway Model No: PS-20-2N11CD

Century Motor C48AA70A79R

115V; 2-Speed; 2-HP

AMPS 13.5/4.7

RPM 3450/1725

My New Motor Specs:

BN50V1

115V; 2-Speed; 1.5 HP

AMPS 13.5/4.7

RPM 3450/1725

Additional Parts Required:

Impeller, 1.5 HP: Mfr P/N 310-5100

Shaft Seal: Mfr P/N 319-3010B; or cross-ref to PS-200V-CMS (You can verify your shaft seal at: U.S. Seal MFG. HERE)

Faceplate O-ring (Small): Mfr P/N 805-0330

Volute Housing O-ring (Large): Mfr P/N 805-0001-SPL

STEP 1: Power off (unplug or turn-off breaker)

STEP 2: Close-off valves to the equipment pad and drain water from the pump and filter. This will help keep the area clean once you separate everything.

NOTE: Other pumps have a separate motor mounting plate, seal plate (and seal) which allows you to remove (pull) the motor from the pump basket (wet end) while still connected to plumbing. Unfortunately these pumps have the motor mated to a volute housing which contains the impeller. The plumbing must be disconnected to separate the strainer pot, volute, and motor.

STEP 3: Remove the pump from the equipment pad.

STEP 5: Remove the 8 screws which hold the faceplate to the volute. This will expose the impeller.

STEP 6: Remove impeller. Do this by first removing the rear motor access cover. If you see a center shaft slot for a large screwdriver, use that to secure the center motor shaft. If there is no screw slot, you’ll need a 7/16 open-ended wrench to slip behind the V-shaped center switch to reach and secure the center shaft. Once you have the center shaft secured, you should be able to remove the impeller (counterclockwise). If the impeller is stuck, use a strap wrench to grip the impeller and turn it. If you use any other type of wrench or pliers you run the risk of damaging the impeller.

STEP 7: Remove the impeller housing (volute). To do this, you loosen the four long “thru-bolts located at the rear of the motor. Once loosened, the volute housing should be removed. The volute cosmetic ring/cover may also be removed. Some models it is permanently affixed to the rear of the housing.

STEP 8: Remove the power cord and 2-speed toggle switch (if installed) from the old motor for use on the new motor if needed. HINT: Take a pic of the wiring for future reference just in case.

STEP 9: Remove the old shaft seal parts from the volute housing and impeller.

STEP 10: Install the new shaft seal parts into the volute and impeller. Be careful to not touch the ceramic/carbon surfaces of either part of the seal as they are designed to be pristine and clean as they spin against each other once assembled.

STEP 12: Align/attach the volute housing onto the front of the motor and secure with the four thru-bolts/nuts. If the decorative volute ring was removed earlier, you can attached it as well.

STEP 13: Attach the impeller. Remember, you have to secure/stabilize the motor’s center shaft bolt with either a large flathead screwdriver or 7/16 open-ended wrench to keep it from spinning. Now spin the impeller onto the front of the motor shaft clockwise by hand (no tools) until snug. Do NOT overtighten.

STEP 14: Lube and affix a new (large) O-ring to the volute housing.

STEP 15: Attach the faceplate to the volute housing using the 8 screws.

STEP 16: Lube and affix a new faceplate (small) O-ring to the front of the faceplate.

STEP 17: Attach the old power cord and 2-speed toggle switch to the new motor, paying close attention to the wiring configuration for your motor (115V or 230V). Make sure this is correct!

STEP 18: Attach the pump strainer pot to the faceplate; secure with the basket clip inside the pot.

STEP 19: Reconnect the pump assembly at the equipment pad:

STEP 21: Turn-on the pump and ensure it remains primed with water. Inspect areas for leaks or odd sounds.

Good luck!

NOTE: If you are swapping the entire pump assembly from Waterway to Hayward Powerflo or visa-versa, know that while both have 1.5 inch “Internal” port threads, the Wateway’s “external” threads differ from the Hayward. So if your plumbing is connected to the pump by the external union nuts, be prepared to change the fittings for external threads or convert to the 1.5 inch internal port threads.

Waterway Supreme parts illustration: POOL PUMPS & PARTS : SUPREME PUMP PARTS - Waterway Parts Pool Supplies

Hayward Powerflo Matrix parts illustration: Hayward PowerFlo Matrix Pump Parts - INYOPools.com

My factory-installed pump & motor info:

Waterway Supreme Pump P/N: PS2200-6

Waterway Model No: PS-20-2N11CD

Century Motor C48AA70A79R

115V; 2-Speed; 2-HP

AMPS 13.5/4.7

RPM 3450/1725

My New Motor Specs:

BN50V1

115V; 2-Speed; 1.5 HP

AMPS 13.5/4.7

RPM 3450/1725

Additional Parts Required:

Impeller, 1.5 HP: Mfr P/N 310-5100

Shaft Seal: Mfr P/N 319-3010B; or cross-ref to PS-200V-CMS (You can verify your shaft seal at: U.S. Seal MFG. HERE)

Faceplate O-ring (Small): Mfr P/N 805-0330

Volute Housing O-ring (Large): Mfr P/N 805-0001-SPL

STEP 1: Power off (unplug or turn-off breaker)

STEP 2: Close-off valves to the equipment pad and drain water from the pump and filter. This will help keep the area clean once you separate everything.

NOTE: Other pumps have a separate motor mounting plate, seal plate (and seal) which allows you to remove (pull) the motor from the pump basket (wet end) while still connected to plumbing. Unfortunately these pumps have the motor mated to a volute housing which contains the impeller. The plumbing must be disconnected to separate the strainer pot, volute, and motor.

STEP 3: Remove the pump from the equipment pad.

- Confirm power cord is unplugged or disconnected from the power source, disconnect ground wire.

- Disconnect the plumbing from the inlet & outlet to the pump.

- Unscrew the pump from the pad.

- Take the entire pump assembly to a table or workbench where you can work comfortably.

STEP 5: Remove the 8 screws which hold the faceplate to the volute. This will expose the impeller.

STEP 6: Remove impeller. Do this by first removing the rear motor access cover. If you see a center shaft slot for a large screwdriver, use that to secure the center motor shaft. If there is no screw slot, you’ll need a 7/16 open-ended wrench to slip behind the V-shaped center switch to reach and secure the center shaft. Once you have the center shaft secured, you should be able to remove the impeller (counterclockwise). If the impeller is stuck, use a strap wrench to grip the impeller and turn it. If you use any other type of wrench or pliers you run the risk of damaging the impeller.

STEP 7: Remove the impeller housing (volute). To do this, you loosen the four long “thru-bolts located at the rear of the motor. Once loosened, the volute housing should be removed. The volute cosmetic ring/cover may also be removed. Some models it is permanently affixed to the rear of the housing.

STEP 8: Remove the power cord and 2-speed toggle switch (if installed) from the old motor for use on the new motor if needed. HINT: Take a pic of the wiring for future reference just in case.

STEP 9: Remove the old shaft seal parts from the volute housing and impeller.

STEP 10: Install the new shaft seal parts into the volute and impeller. Be careful to not touch the ceramic/carbon surfaces of either part of the seal as they are designed to be pristine and clean as they spin against each other once assembled.

- On the volute housing, the white ceramic side faces out/forward (towards the impeller). Place a clean cloth over the ceramic side as you press it into the housing. If it’s tight, you may use a small amount of soapy water on the rubber side/end of the seal to help it slide into the volute cavity. Be sure to press the seal straight and evenly all the way into the cavity. Some people will use a 1-inch socket, or a 1-inch PVC coupling to serve as a press. Remember, protect the ceramic surface!

- On the impeller, the metal side of the seal goes against the impeller body. The carbon side of the seal faces backwards towards the volute to rub against the other (ceramic) part of the seal. Again, be careful not to touch the face of the seal as you twist/press the metal side of the seal flush against the impeller body. If it’s tight, you can use some soapy water here as well.

STEP 12: Align/attach the volute housing onto the front of the motor and secure with the four thru-bolts/nuts. If the decorative volute ring was removed earlier, you can attached it as well.

STEP 13: Attach the impeller. Remember, you have to secure/stabilize the motor’s center shaft bolt with either a large flathead screwdriver or 7/16 open-ended wrench to keep it from spinning. Now spin the impeller onto the front of the motor shaft clockwise by hand (no tools) until snug. Do NOT overtighten.

STEP 14: Lube and affix a new (large) O-ring to the volute housing.

STEP 15: Attach the faceplate to the volute housing using the 8 screws.

STEP 16: Lube and affix a new faceplate (small) O-ring to the front of the faceplate.

STEP 17: Attach the old power cord and 2-speed toggle switch to the new motor, paying close attention to the wiring configuration for your motor (115V or 230V). Make sure this is correct!

STEP 18: Attach the pump strainer pot to the faceplate; secure with the basket clip inside the pot.

STEP 19: Reconnect the pump assembly at the equipment pad:

- Connect PVC plumbing to inlet & outlet of pump; use Teflon tape on threads to prevent leaks.

- Secure the pump assembly to the base of the pad.

- Connect the grounding cable to the motor housing; connect power cord to power source/timer or plug into outlet.

STEP 21: Turn-on the pump and ensure it remains primed with water. Inspect areas for leaks or odd sounds.

Good luck!

Hayward Cartridge Filter Locking Knob Repair

- By Texas Splash

- Pumps, Filters, and Plumbing

- 13 Replies

(UPDATED 11 Mar 2021) The following was used on my Hayward C1200, but may also apply to other Hayward-series cartridge filters that utilize the locking knob on top. These procedures should help those who find that their locking knob on top doesn't seem to fully disengage from the threaded rod inside the filter. Thus, it may seem like the top part of the filter is still stuck to the bottom, or that the knob is released from the rod when actually it is not.

Common problem: The retaining ring (e-clip) that holds the knob tightly against the top housing has rusted apart, therefore it is not fully seated on the knob shaft and/or allows the knob to just spin on the rod inside.

Objective #1 - Get that top part of the housing off. That takes some patience. I used a continuous pulling action as I tried to turn the knob counterclockwise to help disengage it from the inside rod. Even then it still felt stuck. If that doesn't work, you may try the opposite by keeping "downward" pressure on the knob as you unscrew it. Then I grabbed the top house housing near its bottom "lip" which helped give me leverage to pull stronger and remove it.

Here is a pic of the inside of the housing. Notice the white concave shell that guides the top portion over the rod. To remove it, simply insert your finger into the small hole and pull firmly. It should pop out. If stuck, use some pliers on the outer lip and gently pull it off.

Next image you see one of the nylon washers and what's left of my rusted retaining ring (e-clip).

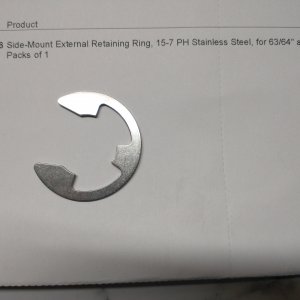

Now you need to purchase a new one-inch "e-clip". Below is one I got from Lowe's (2-pack) for about $1.50 (P/N 881403). But that steel e-clip should only be used temporarily to get your filter back on as the steel will rust too fast.

Ideally you want a stainless steel e-clip. If you shop on-line you'll find some pool stores selling this e-clip for about $11. HERE is an e-clip from Amazon for about $11.00. I opted for the e-clip you see below from McMasters-Carr. While I had to pay shipping of about $10.00, each clip was only a little over $2.00, so I got two of them for about $15.00.

After you wipe-off the area inside, you'll slip the nylon washer back into position. Make sure the locking knob is fully pressed down "into" the housing so the stem is protruding inside as much as it will go. You need access to the tiny grove at the end of that stem so you can slip the new e-clip into place. If you find that the groove at the end of the handle stem is clogged with rust, remove the knob assembly in its entirety to clean-out the groove so it will accept a new e-clip. Lube everything well with pool silicone when you put it back together.

The e-clip holds the nylon washer in-place and also keeps the locking knob pulled-in tightly inside the housing. It may seem a bit tricky to squeeze that e-clip back on, but some needle nose pliers should help. The video below will show you how.

Once done, it should look like this:

Login to view embedded media

I think that about covers it. Good luck!

Common problem: The retaining ring (e-clip) that holds the knob tightly against the top housing has rusted apart, therefore it is not fully seated on the knob shaft and/or allows the knob to just spin on the rod inside.

Objective #1 - Get that top part of the housing off. That takes some patience. I used a continuous pulling action as I tried to turn the knob counterclockwise to help disengage it from the inside rod. Even then it still felt stuck. If that doesn't work, you may try the opposite by keeping "downward" pressure on the knob as you unscrew it. Then I grabbed the top house housing near its bottom "lip" which helped give me leverage to pull stronger and remove it.

Here is a pic of the inside of the housing. Notice the white concave shell that guides the top portion over the rod. To remove it, simply insert your finger into the small hole and pull firmly. It should pop out. If stuck, use some pliers on the outer lip and gently pull it off.

Next image you see one of the nylon washers and what's left of my rusted retaining ring (e-clip).

Now you need to purchase a new one-inch "e-clip". Below is one I got from Lowe's (2-pack) for about $1.50 (P/N 881403). But that steel e-clip should only be used temporarily to get your filter back on as the steel will rust too fast.

Ideally you want a stainless steel e-clip. If you shop on-line you'll find some pool stores selling this e-clip for about $11. HERE is an e-clip from Amazon for about $11.00. I opted for the e-clip you see below from McMasters-Carr. While I had to pay shipping of about $10.00, each clip was only a little over $2.00, so I got two of them for about $15.00.

After you wipe-off the area inside, you'll slip the nylon washer back into position. Make sure the locking knob is fully pressed down "into" the housing so the stem is protruding inside as much as it will go. You need access to the tiny grove at the end of that stem so you can slip the new e-clip into place. If you find that the groove at the end of the handle stem is clogged with rust, remove the knob assembly in its entirety to clean-out the groove so it will accept a new e-clip. Lube everything well with pool silicone when you put it back together.

The e-clip holds the nylon washer in-place and also keeps the locking knob pulled-in tightly inside the housing. It may seem a bit tricky to squeeze that e-clip back on, but some needle nose pliers should help. The video below will show you how.

Once done, it should look like this:

Login to view embedded media

I think that about covers it. Good luck!

Circupool RJ-45 Production Test

- By Texas Splash

- Salt Water Chlorine Generators (SWG)

- 115 Replies

Fellow RJ-45 owners, I am curious to know what type of FC production you are seeing with your SWG - specifically an overnight GAIN test. For my pool, just under 18K, the PoolMath APP shows that my cell should provide ~3.9 ppm of chlorine in 7 hours at 100% output. I have conducted four overnight gain tests and I am not seeing that much production in 7 hrs. To maximize overnight gain potential, I cleaned my cell twice, water is crystal clear, and I passed two OCLTs. Never an error on the module. Still, the most I've gained in 7 hrs is 2.5 ppm, so I'm on the fence of whether to pursue a warranty claim. The reason I started this overnight gain testing to begin with is because some of my daytime FC tests seemed to be falling a bit, so I wanted to take the sun out of the equation.

I understand several variables can influence this overnight gain result such as FC testing, an acceptable OCLT loss of 1 ppm, programmed estimates of the PoolMath APP, and the cell itself, but I wonder if my overnight FC gains are typical of fellow RJ-45 owners. So if any of you have done am overnight gain test recently, or are curious about the performance of your own SWG and wish to share those results here, feel free. Below is a snapshot of my test.

UNIT: RJ-45+

AGE: 27 months

HOURS (Nighttime) TESTED: 7

OUTPUT SETTING: 100%

PROJECTED FC OUTPUT (per Poolmath) - 3.9 ppm

ACTUAL FC OUTPUT: 2.5

I understand several variables can influence this overnight gain result such as FC testing, an acceptable OCLT loss of 1 ppm, programmed estimates of the PoolMath APP, and the cell itself, but I wonder if my overnight FC gains are typical of fellow RJ-45 owners. So if any of you have done am overnight gain test recently, or are curious about the performance of your own SWG and wish to share those results here, feel free. Below is a snapshot of my test.

UNIT: RJ-45+

AGE: 27 months

HOURS (Nighttime) TESTED: 7

OUTPUT SETTING: 100%

PROJECTED FC OUTPUT (per Poolmath) - 3.9 ppm

ACTUAL FC OUTPUT: 2.5

Simple Automation with Shelly - Air in pump detection

- By peterolson07

- Everything Else

- 20 Replies

TL;DR Use Shelly relay's to automate the pool timer and swg autooff if pump is off. Also use home assistant to check if there is air in the pump using power monitoring. This is not a full how-to, just an overview.

Last year I put up a 21' AGP. When I running my electrical, I wanted an easy way to schedule my pump and SWG. There are a million smart plugs out there, but it seemed like Home | Shelly Cloud were some of the best for compatibility and security (you don't need to use there cloud if you don't want). I've been very happy with the result.

What I am doing with shelly:

- Turn on my pump and SWG remotely (in my house, at work, wherever)

- Schedule my pump and SWG

- Set timers on my SWG and pump

- view on-off logs to see when it ran

Basic Equipment:

- 2 shelly 1pm's Shelly 1PM | Shelly Cloud

- 2 standard paddle switches

- Modification: I converted a couple paddle switches to momentary switches using this video: Login to view embedded media - All wiring and gang boxes needed for exterior use.

Some simple automations using Shelly "Scenes"

- Turn off SWG if the pump is turned off

- Turn on the pump if the SWG is turned on.

Advanced - Problem and solution

This is my second season with the pool and I have an air leak on the intake side. Its not a bad leak and only shows itself if the skimmer is getting clogged (I use hair nets in the skimmer which can get clogged). I would also find kids toys stuck in the skimmer flap. I kept finding my pump running dry... not good.

Since I bought the Shelly 1pm's, they have power monitoring. When my pump is running on high it pulls about 975-1013 watts. If its on low, it pulls around 200 watts.

I realized that when there is air in the pump, the wattage drops quite a bit. On high it will drop below 900 watts, on low it will drop below 190 watts.

Shelly doesn't look like they have a great way to do this in their "scenes" so I installed a program called Home Assistant. I'd never used it before but had a file server running in my basement and just installed it right there.

Home assistant detected and added my shelly's instantly. It was super easy and required zero coding, I could do it all in the web interface.

My simple automation - Detect water in the pump, turn it off and notify me:

When the pump is on high speed -

- Trigger: pump power is <900w for at least 30 sec.

- Condition: if pump power is >500w (this is so it doesn't trigger when the pump is in low speed mode) & the pump is on

- action: turn off the pump & notify me with notify.notify (this is basically just the android app). This will notify me and my wife.

When the pump is on low speed-

- Trigger: pump power is <195w for at least 30 sec.

- Condition: if pump power is >1w & the pump is on

- action: turn off the pump & notify me with notify.notify (this is basically just the android app). This will notify me and my wife.

Conclusion:

I'm very happy with my simple low effort solution. It didn't take a lot of time and it runs perfectly.

In the future I'm going to add a thermometer to one of the shelly's and setup home assistant to do temperature logging of my pool water into a google sheet. I want to better understand how the pool temps fluctuate with outdoor temps

Last year I put up a 21' AGP. When I running my electrical, I wanted an easy way to schedule my pump and SWG. There are a million smart plugs out there, but it seemed like Home | Shelly Cloud were some of the best for compatibility and security (you don't need to use there cloud if you don't want). I've been very happy with the result.

What I am doing with shelly:

- Turn on my pump and SWG remotely (in my house, at work, wherever)

- Schedule my pump and SWG

- Set timers on my SWG and pump

- view on-off logs to see when it ran

Basic Equipment:

- 2 shelly 1pm's Shelly 1PM | Shelly Cloud

- 2 standard paddle switches

- Modification: I converted a couple paddle switches to momentary switches using this video: Login to view embedded media - All wiring and gang boxes needed for exterior use.

Some simple automations using Shelly "Scenes"

- Turn off SWG if the pump is turned off

- Turn on the pump if the SWG is turned on.

Advanced - Problem and solution

This is my second season with the pool and I have an air leak on the intake side. Its not a bad leak and only shows itself if the skimmer is getting clogged (I use hair nets in the skimmer which can get clogged). I would also find kids toys stuck in the skimmer flap. I kept finding my pump running dry... not good.

Since I bought the Shelly 1pm's, they have power monitoring. When my pump is running on high it pulls about 975-1013 watts. If its on low, it pulls around 200 watts.

I realized that when there is air in the pump, the wattage drops quite a bit. On high it will drop below 900 watts, on low it will drop below 190 watts.

Shelly doesn't look like they have a great way to do this in their "scenes" so I installed a program called Home Assistant. I'd never used it before but had a file server running in my basement and just installed it right there.

Home assistant detected and added my shelly's instantly. It was super easy and required zero coding, I could do it all in the web interface.

My simple automation - Detect water in the pump, turn it off and notify me:

When the pump is on high speed -

- Trigger: pump power is <900w for at least 30 sec.

- Condition: if pump power is >500w (this is so it doesn't trigger when the pump is in low speed mode) & the pump is on

- action: turn off the pump & notify me with notify.notify (this is basically just the android app). This will notify me and my wife.

When the pump is on low speed-

- Trigger: pump power is <195w for at least 30 sec.

- Condition: if pump power is >1w & the pump is on

- action: turn off the pump & notify me with notify.notify (this is basically just the android app). This will notify me and my wife.

Conclusion:

I'm very happy with my simple low effort solution. It didn't take a lot of time and it runs perfectly.

In the future I'm going to add a thermometer to one of the shelly's and setup home assistant to do temperature logging of my pool water into a google sheet. I want to better understand how the pool temps fluctuate with outdoor temps

An fun observation......

- By jokael

- Testing and Balancing Your Water

- 7 Replies

The weekend, the youngest had a load of his friends over for a "pool party" (they're 11 years old), so I had bumped the FC up to 10-ish.

Later that day, a relative came with her 3-year-old to swim.

Her comment: "Oh, it's just so nice to swim in a pool without chlorine - everyone I know loads it up so it stinks like a public swimmingpool. Yours is much healthier for the little one".........

I didn't tell her that I probably had 8-10 times as much chlorine in our pool than those she refers to (the ones who go by "1-3 ppm max" and only uses pucks)

(the ones who go by "1-3 ppm max" and only uses pucks)

Later that day, a relative came with her 3-year-old to swim.

Her comment: "Oh, it's just so nice to swim in a pool without chlorine - everyone I know loads it up so it stinks like a public swimmingpool. Yours is much healthier for the little one".........

I didn't tell her that I probably had 8-10 times as much chlorine in our pool than those she refers to

Retiring Rita

- By MyAZPool

- Pool Cleaners

- 19 Replies

Well, after nearly two years of procrastinating and taking some friendly ribbing by @Katodude for not living in the 21st century, I finally decided to pull the trigger on a Maytronics robot.

So, I will now be retiring Rita Hayward (aka Hayworth) into mothballs. Rita has been my trusty Hayward Aquanaut 400 Suction-Side Cleaner. She was a literal tank that I could not kill. But it’s now time for her to rest in peace.

I’ll only bring her out of mothballs if something goes really bad with the Maytronics unit and I have to send it in for repairs. I can only hope that my new Matronics Robot lives as long as Rita did (7 years).

Being on TFP for a while now, I had seen enough threads to know that I should direct my initial questions to Margaret at Marina Pool, Spa & Patio.

Man, trying to get a hold of her was a challenge because those folks are busy. But once I did, the hassles of busy signals, leaving messages, missing calls etc., was well worth it. She knows her stuff. Period….. We talked about the size and shape of my pool and what my requirements were.

My requirements were:

1. The unit HAD to have “Automation Mode” capability.

2. I wanted a caddy to accommodate the control unit and move and store the unit during those times when she was not in the pool.

3. I didn’t care about all of the Bluetooth/WiFi enabled features and gidgets and gadgets.

Well, once you want Automation Mode and a caddy, I discovered that you’re going to get all of the other bells and whistles, whether you want them or not.

The units that fit my requirements were:

1. Active 30i/S300i

2. Active 60/M600

Here are some things that I learned during my conversation with Margaret.

1. That the M400 and M500 have been replaced by the M600.

2. I also learned that the only difference between the Active 30i and S300i, Active 60 and M600, as well as the Active 20/S200 and Active 30/S300 is nothing more than color. The “Active’s” are lighter in color (light grey and blue) and the S or M series are darker in color (blue).

So now it was down to the Active 30i (S300i is out of stock) and the Active 60/M600. Here are the difference between the two sets.

1. The Active 60/M600 has a 3-year warranty versus 2-year for the Active30i/S300i

2. The suction rate for the Active 60/M600 is 5000 gallons an hour versus 3,735 gallons per hour (no big deal here).

3. The Active 60/M600 is “beefier.” It has a dual drive and a split brush. She said the Active 60/M600 will negotiate obstacles in the pool a bit better.

NOTE: One thing I really appreciated about Margaret at Marina. She does not try to “upsell” you. She genuinely seems completely interested in getting you the right robot for your pool, your requirements and your wallet. She is a real pleasure to deal with over the phone...

She noted that the Active 30i would be perfect for my requirements but I liked the 3-year warranty and the dual drive/split brush feature, so I opted for the Active 60. It was only $400.00 more and you do get a $75.00 rebate from Maytronics, so what the heck.

It was a breeze ordering over the phone and in less than an hour later, I received a shipping notification. Nice!!

Don’t forget… At Marina Pool, Spa & Patio, there are no shipping charges and if you live in the right state (which apparently I do at the moment), NO TAXES…. WooHoo

A VERY IMPORTANT NOTE IF YOU ARE ON THE FENCE REGARDING THE PURCHASE OF A MAYTRONICS ROBOT.

I learned that supplies are dwindling rapidly.. The Maytronic’s are built in Israel and if you are up on current affairs, you can understand the problem. Between that issue and shipping backlog issues due to Covid-19, at some point very soon, these Robot's may not be had until the fall of 2021 or later. So if you’re thinking about purchasing one soon, you might want to “jump off that fence” and move out and grab your phone…. In fact, there are only a few Active 30i’s left in stock at Marina.

In fact, there are only a few Active 30i’s left in stock at Marina.

UPDATE: 5/27/2021

Well, my Maytronics Active 60 arrived via FedEx today.

I unboxed it, put the caddy together and got it into the pool for a test run.

Very impressive. First impressions of this robot are very positive. After watching this monster for awhile, I affectionately named it "Creighton." The way it moves and the apparent ruggedness of the unit reminds me of an M1 Abrams battle tank.

After a 1.5 hour run, I got it out of the pool and checked the filters. Yup, it's doing it's job alright.

Then I proceeded to download the iOS app, get it onto my WiFi network and set about to customizing the configurations, registering with Maytronics and completing warranty information and completing the rebate info.

The app so far seems to be very user friendly.

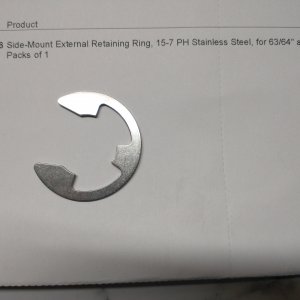

I decided to get the underwater camera out and dove in.

I put together a short video of Creighton at work for anyone who would prefer a real world demo versus watching the promo videos.

Login to view embedded media r.

UPDATE: 6/5/2021

1. I knew that I wanted to use the "Automation Feature". Since the Control Panel/Caddy lives on my patio, I needed to install a GFCI receptacle which is controlled via a Lutron Smart Switch. There was an inside receptacle opposite where I wanted to install the receptacle for the robot, so I set to work.

Here is my solution so I can use the Maytronics Automation Feature.

2. Since I leave "Creighton" in my pool 24x7 and utilize the built-in "Automation Mode" now, I didn't particularly like the control/low voltage power cable running across the patio and kool decking. Not only that, but It was somewhat of a trip hazard.

I decided to put that cable in a cord protector. This is the one that I determined should work out the best for me.

So far, I'm pleased with the result.

3. I may have solved a confliction that typically exists between leaving a surface bot and a Maytronics bot in the water 24x7. Here is a link to that thread.

www.troublefreepool.com

www.troublefreepool.com

r.

So, I will now be retiring Rita Hayward (aka Hayworth) into mothballs. Rita has been my trusty Hayward Aquanaut 400 Suction-Side Cleaner. She was a literal tank that I could not kill. But it’s now time for her to rest in peace.

I’ll only bring her out of mothballs if something goes really bad with the Maytronics unit and I have to send it in for repairs. I can only hope that my new Matronics Robot lives as long as Rita did (7 years).

Being on TFP for a while now, I had seen enough threads to know that I should direct my initial questions to Margaret at Marina Pool, Spa & Patio.

Man, trying to get a hold of her was a challenge because those folks are busy. But once I did, the hassles of busy signals, leaving messages, missing calls etc., was well worth it. She knows her stuff. Period….. We talked about the size and shape of my pool and what my requirements were.

My requirements were:

1. The unit HAD to have “Automation Mode” capability.

2. I wanted a caddy to accommodate the control unit and move and store the unit during those times when she was not in the pool.

3. I didn’t care about all of the Bluetooth/WiFi enabled features and gidgets and gadgets.

Well, once you want Automation Mode and a caddy, I discovered that you’re going to get all of the other bells and whistles, whether you want them or not.

The units that fit my requirements were:

1. Active 30i/S300i

2. Active 60/M600

Here are some things that I learned during my conversation with Margaret.

1. That the M400 and M500 have been replaced by the M600.

2. I also learned that the only difference between the Active 30i and S300i, Active 60 and M600, as well as the Active 20/S200 and Active 30/S300 is nothing more than color. The “Active’s” are lighter in color (light grey and blue) and the S or M series are darker in color (blue).

So now it was down to the Active 30i (S300i is out of stock) and the Active 60/M600. Here are the difference between the two sets.

1. The Active 60/M600 has a 3-year warranty versus 2-year for the Active30i/S300i

2. The suction rate for the Active 60/M600 is 5000 gallons an hour versus 3,735 gallons per hour (no big deal here).

3. The Active 60/M600 is “beefier.” It has a dual drive and a split brush. She said the Active 60/M600 will negotiate obstacles in the pool a bit better.

NOTE: One thing I really appreciated about Margaret at Marina. She does not try to “upsell” you. She genuinely seems completely interested in getting you the right robot for your pool, your requirements and your wallet. She is a real pleasure to deal with over the phone...

She noted that the Active 30i would be perfect for my requirements but I liked the 3-year warranty and the dual drive/split brush feature, so I opted for the Active 60. It was only $400.00 more and you do get a $75.00 rebate from Maytronics, so what the heck.

It was a breeze ordering over the phone and in less than an hour later, I received a shipping notification. Nice!!

Don’t forget… At Marina Pool, Spa & Patio, there are no shipping charges and if you live in the right state (which apparently I do at the moment), NO TAXES…. WooHoo

A VERY IMPORTANT NOTE IF YOU ARE ON THE FENCE REGARDING THE PURCHASE OF A MAYTRONICS ROBOT.

I learned that supplies are dwindling rapidly.. The Maytronic’s are built in Israel and if you are up on current affairs, you can understand the problem. Between that issue and shipping backlog issues due to Covid-19, at some point very soon, these Robot's may not be had until the fall of 2021 or later. So if you’re thinking about purchasing one soon, you might want to “jump off that fence” and move out and grab your phone….

UPDATE: 5/27/2021

Well, my Maytronics Active 60 arrived via FedEx today.

I unboxed it, put the caddy together and got it into the pool for a test run.

Very impressive. First impressions of this robot are very positive. After watching this monster for awhile, I affectionately named it "Creighton." The way it moves and the apparent ruggedness of the unit reminds me of an M1 Abrams battle tank.

After a 1.5 hour run, I got it out of the pool and checked the filters. Yup, it's doing it's job alright.

Then I proceeded to download the iOS app, get it onto my WiFi network and set about to customizing the configurations, registering with Maytronics and completing warranty information and completing the rebate info.

The app so far seems to be very user friendly.

I decided to get the underwater camera out and dove in.

I put together a short video of Creighton at work for anyone who would prefer a real world demo versus watching the promo videos.

Login to view embedded media r.

UPDATE: 6/5/2021

1. I knew that I wanted to use the "Automation Feature". Since the Control Panel/Caddy lives on my patio, I needed to install a GFCI receptacle which is controlled via a Lutron Smart Switch. There was an inside receptacle opposite where I wanted to install the receptacle for the robot, so I set to work.

Here is my solution so I can use the Maytronics Automation Feature.

2. Since I leave "Creighton" in my pool 24x7 and utilize the built-in "Automation Mode" now, I didn't particularly like the control/low voltage power cable running across the patio and kool decking. Not only that, but It was somewhat of a trip hazard.

I decided to put that cable in a cord protector. This is the one that I determined should work out the best for me.

So far, I'm pleased with the result.

3. I may have solved a confliction that typically exists between leaving a surface bot and a Maytronics bot in the water 24x7. Here is a link to that thread.

Ariel Surface bot and Maytronics Dolphin Deconfliction

Last November, I pre-ordered an “Ariel by Solar-Breeze” surface bot. Before the actual delivery of Ariel, I had then decided to also make the switch from a suction-side cleaner to a Dolphin Robot by Maytronics for cleaning the bottom, sides and tile. In my research, I noticed several threads...

r.

New CoverStar LCD Touch Pad

- By wgipe

- Everything Else

- 40 Replies

Our pool build was finalized last year, which included a CoverStar cover with a WiFi Touch Pad. We had lots of problems with connectivity, false over-current messages every time the cover was opened or closed, etc. and CoverStar Central graciously offered to replace our Touch Pad with the new one they were developing as soon as it was released. I can't seem to find much about it online yet, so I've attached a few pictures here. It arrived today, and I just finished installing it. I must say it is an enormous improvement over the previous version. It appears that it still may be in beta based on the firmware upgrade procedure, but I would highly recommend waiting until it is available if you are planning a build this year. Any questions, I'd be glad to answer what I can.

Attachments

We Have a Winner! TFP Pool of the Month (July 2023); Theme - Pets

- By Texas Splash

- About Trouble Free Pool

- 29 Replies

Always a crowd favorite. Let's see your fur-kids in action.

1. On the first of each month, a contest "theme" will be announced (i.e. water clarity, family fun, decking, custom features, lighting, scenery, etc)

2. Members have 10 days to UPLOAD ONE image for consideration; Photo must be related to the thread titled theme for that month.

3. Per general TFP rules, nothing profane, political, or insulting.

4. The first 10 days is the submission period. Posts are limited to ONE image ONLY. No discussion posts yet. This will make viewing much easier for all.

5. Days 11 - 15 the thread will be locked and is for voting only. No more uploads. Viewers now have a final opportunity to vote (or modify their selection) for their favorite upload.

6. Members are encouraged to use an emotion icon ("Like" or "Love") to vote for their favorite upload; it will be tough, but select only one favorite.

7. On day 16, emotion Likes/Loves will be tallied for a winner. In the event of a tie, we will create a poll on the thread to make a final selection.

8. Once a winner is announced, the thread will be unlocked and comments/discussions are welcomed. Winner and nominees can tell us all about their pool/photo/event.

9. A member can only be selected as winner once per calendar year.

10. Winner will receive a $50 gift certificate from tstestkits.net! Oh, and maybe some bragging rights.

This should be fun. Tell your furry family members it's time to go swimming. Let's see your pets in action! Have fun and good luck to those who apply!

1. On the first of each month, a contest "theme" will be announced (i.e. water clarity, family fun, decking, custom features, lighting, scenery, etc)

2. Members have 10 days to UPLOAD ONE image for consideration; Photo must be related to the thread titled theme for that month.

3. Per general TFP rules, nothing profane, political, or insulting.

4. The first 10 days is the submission period. Posts are limited to ONE image ONLY. No discussion posts yet. This will make viewing much easier for all.

5. Days 11 - 15 the thread will be locked and is for voting only. No more uploads. Viewers now have a final opportunity to vote (or modify their selection) for their favorite upload.

6. Members are encouraged to use an emotion icon ("Like" or "Love") to vote for their favorite upload; it will be tough, but select only one favorite.

7. On day 16, emotion Likes/Loves will be tallied for a winner. In the event of a tie, we will create a poll on the thread to make a final selection.

8. Once a winner is announced, the thread will be unlocked and comments/discussions are welcomed. Winner and nominees can tell us all about their pool/photo/event.

9. A member can only be selected as winner once per calendar year.

10. Winner will receive a $50 gift certificate from tstestkits.net! Oh, and maybe some bragging rights.

This should be fun. Tell your furry family members it's time to go swimming. Let's see your pets in action! Have fun and good luck to those who apply!

Pool Cover Log

- By SoCalTFP

- Everything Else

- 10 Replies

Hey Everyone I finally broke down and purchased a pool cover because we were losing so much heat and water overnight with the high temperature we like to heat our pool to. I don't mind the cost, well I do but tell myself the enjoyment is worth it, but I'd prefer to not go through the mental gymnastics of deciding if firing up our gas heater is worth it every time we plan to use the pool. I plan to log some general information for myself and figured someone who's trying to determine if a pool cover is worth the trouble might benefit as well so I'll post up information in this thread.

Background:

We have a ~12k pool/spa that we've owned for the past year in the inland Southern California area. 2 months back we fired the pool guy (after the second algae bloom and major scaling issues) and take up the TFP method. We have plaster finish, IC40 SWG, VSP, Raypack Gas Heater, and a Cartridge Filter. My kids started summer break so I keep the pool heated to ~85 daily, and then crank it up to 90-92 when the adults plan to swim because we like it hot. I have been noticing a large amount of evaporation with the low 50's night temperatures and have been topping the pool off every couple of days instead of weekly, which obviously is also contributing to a massive heat loss. I've been avoiding the Pool Cover since I remember them being a pain and my time is valuable enough that wrangling a sheet of bubble twice a day didn't sound worth it. My wife recently started talking about adding Solar and after some research it sounds like even that route a pool cover would be highly recommended.

A couple of days ago we received the pool cover I ordered. We have a kidney shaped pool with raised overflowing spa. I bought a 16x24 8-mil cover that covers about 80-90% of our pool/spa with some minor overlap on the sides. I planned to do-it-yourself roller with the foam piping and clips that seemed popular on here if needed, and potenially get a second cover to get the spa and non-standard sides that the current cover doesn't cover. Both of those will be based on the next few weeks of testing.

6/21/2023 Log:

I've been timing myself on putting the cover on and off the past couple of times, by myself it takes me less than 4 minutes to put it on and take it off. This morning I rolled it up and we have some outdoor storage that I should be able to place it in to keep it out of the sun and from being an eyesore. Overall my experience with taking it on and off has been extremely easy considering how many people mention they really struggle with these.

Last night the pump shut off ~6pm and was reading 92 degrees for the pool. This morning when it turned on ~6am (circulates water for morning testing) the temp was 87 degrees. I'll be simulating the same temperatures and leaving it off overnight for a couple of nights to log the uncovered temperature loss as well. We're starting off with a full pool (just below refill piping) and will track fill frequency and potentially do some uncovered tests as well.

Free Chlorine (tested with FAS DPD daily) is usually 9-9.5ppm based on CYA 80 without the cover and 0 CC. This morning it was 8.5ppm FC and 0.5ppm CC. I will continue to monitor this but at first glance my assumption is the cover is potentially leading to the slight increase in CC. Also this could just be a minor testing discrepancy. I'll be tracking this because I'd like to better understand how the cover impacts chemical usage in the event I'd like to leave it on during a vacation or if we'd like to stop removing the cover daily in the winter to retain heat for the occasional weekend "pool hot tub" party. PH is 7.6, although I'm a little color blind so I'm never fully confident on that test for .1-2 accuracy.

Given the ease of removal and "close enough" fit I will likely push out my plans to build the DIY roller and custom fitting it to the pool for another week or two unless something changes. My kids are too small to remove it and my wife likely won't want to, so it's pretty much going to fall on me.

My plan is to update this daily (or maybe every couple days). If nothing else it will help me keep my thoughts straight and help someone who's been considering a cover but not sure if it's worth the trouble.

Background:

We have a ~12k pool/spa that we've owned for the past year in the inland Southern California area. 2 months back we fired the pool guy (after the second algae bloom and major scaling issues) and take up the TFP method. We have plaster finish, IC40 SWG, VSP, Raypack Gas Heater, and a Cartridge Filter. My kids started summer break so I keep the pool heated to ~85 daily, and then crank it up to 90-92 when the adults plan to swim because we like it hot. I have been noticing a large amount of evaporation with the low 50's night temperatures and have been topping the pool off every couple of days instead of weekly, which obviously is also contributing to a massive heat loss. I've been avoiding the Pool Cover since I remember them being a pain and my time is valuable enough that wrangling a sheet of bubble twice a day didn't sound worth it. My wife recently started talking about adding Solar and after some research it sounds like even that route a pool cover would be highly recommended.

A couple of days ago we received the pool cover I ordered. We have a kidney shaped pool with raised overflowing spa. I bought a 16x24 8-mil cover that covers about 80-90% of our pool/spa with some minor overlap on the sides. I planned to do-it-yourself roller with the foam piping and clips that seemed popular on here if needed, and potenially get a second cover to get the spa and non-standard sides that the current cover doesn't cover. Both of those will be based on the next few weeks of testing.

6/21/2023 Log:

I've been timing myself on putting the cover on and off the past couple of times, by myself it takes me less than 4 minutes to put it on and take it off. This morning I rolled it up and we have some outdoor storage that I should be able to place it in to keep it out of the sun and from being an eyesore. Overall my experience with taking it on and off has been extremely easy considering how many people mention they really struggle with these.

Last night the pump shut off ~6pm and was reading 92 degrees for the pool. This morning when it turned on ~6am (circulates water for morning testing) the temp was 87 degrees. I'll be simulating the same temperatures and leaving it off overnight for a couple of nights to log the uncovered temperature loss as well. We're starting off with a full pool (just below refill piping) and will track fill frequency and potentially do some uncovered tests as well.

Free Chlorine (tested with FAS DPD daily) is usually 9-9.5ppm based on CYA 80 without the cover and 0 CC. This morning it was 8.5ppm FC and 0.5ppm CC. I will continue to monitor this but at first glance my assumption is the cover is potentially leading to the slight increase in CC. Also this could just be a minor testing discrepancy. I'll be tracking this because I'd like to better understand how the cover impacts chemical usage in the event I'd like to leave it on during a vacation or if we'd like to stop removing the cover daily in the winter to retain heat for the occasional weekend "pool hot tub" party. PH is 7.6, although I'm a little color blind so I'm never fully confident on that test for .1-2 accuracy.

Given the ease of removal and "close enough" fit I will likely push out my plans to build the DIY roller and custom fitting it to the pool for another week or two unless something changes. My kids are too small to remove it and my wife likely won't want to, so it's pretty much going to fall on me.

My plan is to update this daily (or maybe every couple days). If nothing else it will help me keep my thoughts straight and help someone who's been considering a cover but not sure if it's worth the trouble.

Conversion complete (I think!)

- By katwhen31

- Testing and Balancing Your Water

- 17 Replies

Hello! I completed my conversion from Baquacil to chlorine and I’m very happy about it.  My pool looks great and feels great. I did run into a small issue when my just-over-one-year-old Hayward pump started leaking at the shaft.

My pool looks great and feels great. I did run into a small issue when my just-over-one-year-old Hayward pump started leaking at the shaft.  I don’t know if that had anything to do with the conversion but regardless, it’s fine now. I found out pretty quickly that getting someone to replace the seals was going to be difficult and expensive so I bought a repair kit and did it myself!

I don’t know if that had anything to do with the conversion but regardless, it’s fine now. I found out pretty quickly that getting someone to replace the seals was going to be difficult and expensive so I bought a repair kit and did it myself!  (proud of me). No more leaking.

(proud of me). No more leaking.

Now here’s my question:

I’ve been checking the FC every evening when the sun is low and it’s been zero after a day of sun. My CYA is 40. So I’ve been adding chlorine every evening and in the morning sometimes it has dropped a bit, so I add the recommended amount to bring it up.

Will I need to check FC daily and add chlorine every day? Or is something else going on?

I did change out my filter after passing the overnight test twice and the CC has always been <.5

I also plan to add borates but wanted to get the conversion completed before doing anything else.

TIA.

Now here’s my question:

I’ve been checking the FC every evening when the sun is low and it’s been zero after a day of sun. My CYA is 40. So I’ve been adding chlorine every evening and in the morning sometimes it has dropped a bit, so I add the recommended amount to bring it up.

Will I need to check FC daily and add chlorine every day? Or is something else going on?

I did change out my filter after passing the overnight test twice and the CC has always been <.5

I also plan to add borates but wanted to get the conversion completed before doing anything else.

TIA.

Mouse in line to pump basket

- By PegInAz

- Everything Else

- 13 Replies

Help! I found a very small deceased mouse in the top window our Pentair pump and every time we open the lid to remove it from the basket, it flows back into the incoming line. We tried pushing water through the line with a garden hose to see if it comes back up through the pool skimmer, but no luck. After turning on the pool again he comes back into the pump window. Is there a way to lower the water slowly to allow it to fall past that line opening so we can get it out of the basket? So gross to have it in there….

. PS. We replaced all of our Hayward equipment with Pentair a few months ago and our old Hayward pump water level would lower with it turned off, unlike this new one, so everything would drop to the bottom of the basket.

. PS. We replaced all of our Hayward equipment with Pentair a few months ago and our old Hayward pump water level would lower with it turned off, unlike this new one, so everything would drop to the bottom of the basket.

Attachments

-

Locked

Glacier Pool Cooler with Omnilogic Automation DIY in Louisiana

- By twillux

- Everything Else

- 29 Replies

Hello TFP! I just finished a DYI install of a Glacier Pool Cooler and thought I’d share my experience; had done some research on these initially and while it seems they’re fairly popular, I couldn’t find a lot of information on self-installation. Hope this helps anyone else looking to do their own.

Overview: Glacier GPC-25 Pool Cooler, Hayward OmniPL controller, 13k gallon gunnite inground pool.

I’m in south Louisiana and it’s hot! My pool is in full sun most of the day. It’s early summer and the pool is consistently 92-95 degrees, and I’ve even seen it as high as 98 over the past few weeks; basically an un-swimmable, expensive bathtub. I researched both heat pumps and the Glacier, but opted for the latter as it costs basically nothing to run; a heat pump would be fairly expensive at today’s fuel prices. I originally received quotes from both of my local PB’s on the Glacier, and they each quoted about $5k to 5.2k installed, with a delivery in late Fall; while that may be reasonable by today’s pricing, I didn’t want to wait and went forward with a self-install.

The pool is just under two years old, and I’d fortunately designed for a chiller in the event it were ever needed: space on the pad, dedicated return line to the middle-sidewall of the deep end, and T in the plumbing. I opted for the GPC-25, good up to 20k gallons, as the open space on my pad is 2’x2’ and the only gain from a larger chiller is quicker cooling, though not lower temps.

TC Pool Equipment in California had three in stock for $2.3k plus shipping; bought on Monday and delivery on Thursday. First, this thing is big. Thankfully I didn’t go with the 30k gallon GPC-210; the pad I have was barely enough for the 25. The build quality was a little surprising: it looks almost hand-made; lots of small scratches and imperfections in the fiberglass, grating, mesh, etc., though the unit functionally has no issues so far. So, after getting the unit to the pad, it was on to electrical, automation, plumbing and programming.

Electrical: The GPC-25 is a 120VAC/8A single phase unit, comprised of one sump pump and a fan. It has a weather-proof light-switch box on the side, but note that the unit arrived with nothing wired; just a stock on/off switch. I wired both motors to the electrical box, to the ON contact of the switch. From there, I ran 14AWG wiring from the OFF contact through flexible nonmetallic liquid-tight conduit to the OmniPL controller. This will allow me to control on/off from the controller, and use the manual switch on the Glacier as a disconnect if I ever need to force the unit off locally.

Automation: The OmniPL controller has 4 stock high voltage relays (HVR1-4), with room for two more internal (HVR9 and HVR10), plus an external bank of four (HVR5-8). All onboard were already in use, so I ordered an extra HLRELAY and installed as HVR9, and wired to a new Eaton BR10 20A breaker that I installed in a spare slot dedicated to the Chiller. The OmniPL also has room for four temperature sensors; I have two open, so ordered another sensor to plump into the Chiller’s return line to monitor temperature of the cold water return going into the pool. Not sure if the Omni will allow easy monitoring of this not tied to a named heat pump or solar array, but it was worth the try for $20. The last part of the automation was a new 3-way diverter valve and a Hayward GVA-24 actuator to handle water flow connected to a spare valve channel.

Plumbing: This was definitely the hardest part; plumbing is not fun. While I had asked my PB to pre-plumb for a future chiller, I have multiple issues with my plumbing. Specifically in this case, they installed the diverter valve for the chiller upstream of the filter; you can’t run unfiltered water to ANYTHING, so no idea why they did this. I abandoned that valve, and cut my own diverter connection into the piping downstream of the filter, before the heater. This valve and actuator are typically closed to the chiller, but open when set to run and divert some of the water off to the chiller for cooling.

From there, the input is plumbed to a Jandy ball valve, then into the inlet on the chiller. The return to the pool then runs through a new union to the PVC in the pad, and out to the pool return.

The Glacier manual states for new installs that the return line should be in the bottom center of the pool, but I’m glad my PB located it on the lower sidewall; the cooled water will get picked up by both the skimmer and main drain, then easily spread through the plumbing and off to the entire pool.

Each Glacier also has a drain plug that needs a small ball valve on it for quick draining and winterization; the manual states this is 1”, but on the GPC-25 apparently it’s only 3/4”! That cost me one of my 4 Home Depot runs. In addition to the cost of the Glacier, I spent probably another $400 altogether on the electrical, relay, valves, actuator, PVC, glue, sandpaper and other odds and ends.

Programming: Once everything was installed and running, I ran through a bit of programming on the OmniPL to attempt to automate as much as possible. I setup the Chiller as a new Water Feature, tied to the high voltage relay and the actuator. While the Omni doesn’t allow conditional logic, you can do some things within Interlocks. The downside of the Interlocks is that they force states, so you don’t want to force the Chiller to run: you wouldn’t be able to turn it off. Instead, I setup schedules to run the Chiller essentially full-time though outside of the hour or so that I run my VSP on a higher speed to skim. I then configured a bunch of interlocks: do not run the chiller when the heater is running, don’t run the chiller when in Spa mode, don’t run the chiller when the cleaner booster pump is running, don’t run the heater if the chiller is running, don’t run the chiller if the main VSP isn’t running, etc etc.

The key interlocks I then added are to stop the chiller if the water temp drops below 82 degrees, and to stop the chiller if ambient temperature drops below 78 degrees. Still tweaking those setpoints, but the thought is that if either of these cases occur, the pool is already going to be cool enough naturally and I don’t need to bring the temp any further down! Have more to experiment on this front, but hope that this will essentially allow me to set and forget it, though I’ll still have to consider runtime on the VSP.

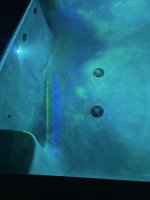

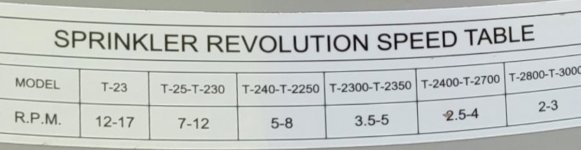

From there, startup was very straightforward. Open the inlet ball valve all the way, start the pump and chiller, then pinch back on the ball valve and attempt to time the spray bars to meet a 7-12 RPM speed. Very small movements on the valve make a big difference in speed, so it takes some tweaking to tune it. As others have said on TFP with these, pump speed also matters; I attempted to start on a low speed of 1,300 RPMs, but this wasn’t pushing enough water to run both the chiller and feed my three pool returns, nor to effectively circulate the chilled pool water. I stepped this up to 1,800 RPMs which seemed plenty, which also moved enough water throughout the pool.

From an operational cost standpoint, my first full day cost only $0.51 to run the chiller, and an additional $0.32 to run the VSP; that’s less than a dollar a day adder. The pool temp dropped from 95 degrees to 86, from 3pm when I finished the install and finally turned it on, to 7am the next morning. This was in 97 degree weather with a heat index of 106 and humidity as high as 88. Pretty impressive, as my pool hasn’t seen below 92 in weeks. We jumped in the pool after having the chiller on for maybe 15 minutes, and the water coming out of the return felt ice cold next to the heat of the surrounding water. Running the chiller the entire next day also held temp to a maximum of 88, well within my desired temperature range, and the change was incredible.

Total installed cost was about $3.1k, saving about two thousand from having it professionally installed. My next steps are to install the temperature sensor and continue to tweak the programming setpoints, pump speed, ball valve setting, etc. and try to find an optimal setup. The rain finally came out and this heat wave seems to have finally passed, so I’m halfway disappointed that I won’t need to run the chiller for at least the next week after all that work!

Hope this was a fun read and provided some information for anyone looking to do the same, and I’d be happy to answer any further specifics if interested.

Cheers!

07/03/2022 Automation Update:

Spent quite a bit of time over the last week trying to find the ideal way to configure the Chiller within the OmniPL. Originally I had it configured as a water feature as described above, but wanted to be able to monitor the return temperature as well. The temp sensor is available and can be read while in service mode, but unfortunately the controller does not expose additional sensors outside of equipment. I tried the chiller as a Solar cooler, but the sensor then acts as a lockout when the cooler is off and the temp is at or above the pool temp. I also considered configuring it as another body of water, but it would have to function as a pump and there are limitations on being able to activate the valve and configure needed interlocks.

I gave up on being able to see return temp outside of service mode (for now until Hayward adds this capability , and ultimately configured it as a chiller within the heat/cool setup alongside my gas heater. This functionality was added to the Omni in a recent firmware, v4.3.x.

, and ultimately configured it as a chiller within the heat/cool setup alongside my gas heater. This functionality was added to the Omni in a recent firmware, v4.3.x.

This works very well and is much simpler, allowing temperature control to set point without having to rely on interlocks, and I can essentially leave the chiller enabled through the summer and it will automatically run as needed.

Overview: Glacier GPC-25 Pool Cooler, Hayward OmniPL controller, 13k gallon gunnite inground pool.

I’m in south Louisiana and it’s hot! My pool is in full sun most of the day. It’s early summer and the pool is consistently 92-95 degrees, and I’ve even seen it as high as 98 over the past few weeks; basically an un-swimmable, expensive bathtub. I researched both heat pumps and the Glacier, but opted for the latter as it costs basically nothing to run; a heat pump would be fairly expensive at today’s fuel prices. I originally received quotes from both of my local PB’s on the Glacier, and they each quoted about $5k to 5.2k installed, with a delivery in late Fall; while that may be reasonable by today’s pricing, I didn’t want to wait and went forward with a self-install.

The pool is just under two years old, and I’d fortunately designed for a chiller in the event it were ever needed: space on the pad, dedicated return line to the middle-sidewall of the deep end, and T in the plumbing. I opted for the GPC-25, good up to 20k gallons, as the open space on my pad is 2’x2’ and the only gain from a larger chiller is quicker cooling, though not lower temps.

TC Pool Equipment in California had three in stock for $2.3k plus shipping; bought on Monday and delivery on Thursday. First, this thing is big. Thankfully I didn’t go with the 30k gallon GPC-210; the pad I have was barely enough for the 25. The build quality was a little surprising: it looks almost hand-made; lots of small scratches and imperfections in the fiberglass, grating, mesh, etc., though the unit functionally has no issues so far. So, after getting the unit to the pad, it was on to electrical, automation, plumbing and programming.

Electrical: The GPC-25 is a 120VAC/8A single phase unit, comprised of one sump pump and a fan. It has a weather-proof light-switch box on the side, but note that the unit arrived with nothing wired; just a stock on/off switch. I wired both motors to the electrical box, to the ON contact of the switch. From there, I ran 14AWG wiring from the OFF contact through flexible nonmetallic liquid-tight conduit to the OmniPL controller. This will allow me to control on/off from the controller, and use the manual switch on the Glacier as a disconnect if I ever need to force the unit off locally.

Automation: The OmniPL controller has 4 stock high voltage relays (HVR1-4), with room for two more internal (HVR9 and HVR10), plus an external bank of four (HVR5-8). All onboard were already in use, so I ordered an extra HLRELAY and installed as HVR9, and wired to a new Eaton BR10 20A breaker that I installed in a spare slot dedicated to the Chiller. The OmniPL also has room for four temperature sensors; I have two open, so ordered another sensor to plump into the Chiller’s return line to monitor temperature of the cold water return going into the pool. Not sure if the Omni will allow easy monitoring of this not tied to a named heat pump or solar array, but it was worth the try for $20. The last part of the automation was a new 3-way diverter valve and a Hayward GVA-24 actuator to handle water flow connected to a spare valve channel.

Plumbing: This was definitely the hardest part; plumbing is not fun. While I had asked my PB to pre-plumb for a future chiller, I have multiple issues with my plumbing. Specifically in this case, they installed the diverter valve for the chiller upstream of the filter; you can’t run unfiltered water to ANYTHING, so no idea why they did this. I abandoned that valve, and cut my own diverter connection into the piping downstream of the filter, before the heater. This valve and actuator are typically closed to the chiller, but open when set to run and divert some of the water off to the chiller for cooling.

From there, the input is plumbed to a Jandy ball valve, then into the inlet on the chiller. The return to the pool then runs through a new union to the PVC in the pad, and out to the pool return.

The Glacier manual states for new installs that the return line should be in the bottom center of the pool, but I’m glad my PB located it on the lower sidewall; the cooled water will get picked up by both the skimmer and main drain, then easily spread through the plumbing and off to the entire pool.

Each Glacier also has a drain plug that needs a small ball valve on it for quick draining and winterization; the manual states this is 1”, but on the GPC-25 apparently it’s only 3/4”! That cost me one of my 4 Home Depot runs. In addition to the cost of the Glacier, I spent probably another $400 altogether on the electrical, relay, valves, actuator, PVC, glue, sandpaper and other odds and ends.

Programming: Once everything was installed and running, I ran through a bit of programming on the OmniPL to attempt to automate as much as possible. I setup the Chiller as a new Water Feature, tied to the high voltage relay and the actuator. While the Omni doesn’t allow conditional logic, you can do some things within Interlocks. The downside of the Interlocks is that they force states, so you don’t want to force the Chiller to run: you wouldn’t be able to turn it off. Instead, I setup schedules to run the Chiller essentially full-time though outside of the hour or so that I run my VSP on a higher speed to skim. I then configured a bunch of interlocks: do not run the chiller when the heater is running, don’t run the chiller when in Spa mode, don’t run the chiller when the cleaner booster pump is running, don’t run the heater if the chiller is running, don’t run the chiller if the main VSP isn’t running, etc etc.

The key interlocks I then added are to stop the chiller if the water temp drops below 82 degrees, and to stop the chiller if ambient temperature drops below 78 degrees. Still tweaking those setpoints, but the thought is that if either of these cases occur, the pool is already going to be cool enough naturally and I don’t need to bring the temp any further down! Have more to experiment on this front, but hope that this will essentially allow me to set and forget it, though I’ll still have to consider runtime on the VSP.

From there, startup was very straightforward. Open the inlet ball valve all the way, start the pump and chiller, then pinch back on the ball valve and attempt to time the spray bars to meet a 7-12 RPM speed. Very small movements on the valve make a big difference in speed, so it takes some tweaking to tune it. As others have said on TFP with these, pump speed also matters; I attempted to start on a low speed of 1,300 RPMs, but this wasn’t pushing enough water to run both the chiller and feed my three pool returns, nor to effectively circulate the chilled pool water. I stepped this up to 1,800 RPMs which seemed plenty, which also moved enough water throughout the pool.

From an operational cost standpoint, my first full day cost only $0.51 to run the chiller, and an additional $0.32 to run the VSP; that’s less than a dollar a day adder. The pool temp dropped from 95 degrees to 86, from 3pm when I finished the install and finally turned it on, to 7am the next morning. This was in 97 degree weather with a heat index of 106 and humidity as high as 88. Pretty impressive, as my pool hasn’t seen below 92 in weeks. We jumped in the pool after having the chiller on for maybe 15 minutes, and the water coming out of the return felt ice cold next to the heat of the surrounding water. Running the chiller the entire next day also held temp to a maximum of 88, well within my desired temperature range, and the change was incredible.

Total installed cost was about $3.1k, saving about two thousand from having it professionally installed. My next steps are to install the temperature sensor and continue to tweak the programming setpoints, pump speed, ball valve setting, etc. and try to find an optimal setup. The rain finally came out and this heat wave seems to have finally passed, so I’m halfway disappointed that I won’t need to run the chiller for at least the next week after all that work!

Hope this was a fun read and provided some information for anyone looking to do the same, and I’d be happy to answer any further specifics if interested.

Cheers!

07/03/2022 Automation Update:

Spent quite a bit of time over the last week trying to find the ideal way to configure the Chiller within the OmniPL. Originally I had it configured as a water feature as described above, but wanted to be able to monitor the return temperature as well. The temp sensor is available and can be read while in service mode, but unfortunately the controller does not expose additional sensors outside of equipment. I tried the chiller as a Solar cooler, but the sensor then acts as a lockout when the cooler is off and the temp is at or above the pool temp. I also considered configuring it as another body of water, but it would have to function as a pump and there are limitations on being able to activate the valve and configure needed interlocks.

I gave up on being able to see return temp outside of service mode (for now until Hayward adds this capability

This works very well and is much simpler, allowing temperature control to set point without having to rely on interlocks, and I can essentially leave the chiller enabled through the summer and it will automatically run as needed.

How to test for Iron without sending out water to testing lab or pool store! (pics included)

- By jesse-99

- The Deep End...

- 17 Replies

I originally posted this in another thread regarding an AA treatment another TFP'er is going through but I felt it warranted it's own thread specifically.

If anyone is concerned their fill water or auto-fill water has Iron in it, you can do a 5-gallon white-bucket test with your water.

Here's my side by side comparisons. One 5-gallon bucket that has iron in it, one 5-gallon bucket that doesn't have iron in it (because my dual Water Softener removed the iron through an ion exchange process).

From 8:55am

Left Bucket: Filled from Well, and passed through 4 13x52 iron filters.

Right Bucket: Filled from Well, and passed through 4 13x52 iron filters and through dual tank Water Softener

From 9:15am (20 mins later)

Left Bucket: Filled from Well, and passed through 4 13x52 iron filters, and 1TBS of 12.5% chlorine (mixed)

Right Bucket: Filled from Well, and passed through 4 13x52 iron filters and through dual tank Water Softener, and 1TBS of 12.5% chlorine (mixed)

From 9:55am (1 hour later)

Left Bucket: Filled from Well, and passed through 4 13x52 iron filters, and 1TBS of 12.5% chlorine (mixed)

Right Bucket: Filled from Well, and passed through 4 13x52 iron filters and through dual tank Water Softener, and 1TBS of 12.5% chlorine (mixed)

Note: The FC is 23PPM in the 2nd and 3rd picture, and STILL no changing of the color in the 5-gallon bucket that was filled through my Soft Water system. (yes, 23PPM, I verified/tested with my Taylor kit)

I know it's not scientific but, anyone that wants to check for Iron in their fill/auto-fill water, can EASILY do this and not have to pay for testing (and we also know LOTS of people "test' for Iron and get results of 0ppm even though they have Iron in their pool, proven from Vitamin-C testing on the stains they have!) So I feel this test is more accurate than some of the actual iron "testing" done by stores or labs and basically costs *nothing* ... If anyone thinks this iron-test isn't valid please add your input, I'm no science wizard and plenty of smarter people on TFP than I am.

Hope this helps some people.

EDIT: Crud, I can't remember if it was 1TBS or 1TSP that I added. Please note. In hindsight I'm thinking maybe it was a TSP (the smaller amount).

2ND EDIT: Clarifying I'm using a 5-gallon bucket.

If anyone is concerned their fill water or auto-fill water has Iron in it, you can do a 5-gallon white-bucket test with your water.

- Iron in water (without ANY chlorine) will be in a solution state, meaning it's invisible to the eye.

- Iron in water (with chlorine added) will go into a suspension state, meaning it's visible to the eye (caveat: assuming NO sequestrants are in the test water)

Here's my side by side comparisons. One 5-gallon bucket that has iron in it, one 5-gallon bucket that doesn't have iron in it (because my dual Water Softener removed the iron through an ion exchange process).

From 8:55am

Left Bucket: Filled from Well, and passed through 4 13x52 iron filters.

Right Bucket: Filled from Well, and passed through 4 13x52 iron filters and through dual tank Water Softener

From 9:15am (20 mins later)

Left Bucket: Filled from Well, and passed through 4 13x52 iron filters, and 1TBS of 12.5% chlorine (mixed)

Right Bucket: Filled from Well, and passed through 4 13x52 iron filters and through dual tank Water Softener, and 1TBS of 12.5% chlorine (mixed)

From 9:55am (1 hour later)

Left Bucket: Filled from Well, and passed through 4 13x52 iron filters, and 1TBS of 12.5% chlorine (mixed)

Right Bucket: Filled from Well, and passed through 4 13x52 iron filters and through dual tank Water Softener, and 1TBS of 12.5% chlorine (mixed)

Note: The FC is 23PPM in the 2nd and 3rd picture, and STILL no changing of the color in the 5-gallon bucket that was filled through my Soft Water system. (yes, 23PPM, I verified/tested with my Taylor kit)

I know it's not scientific but, anyone that wants to check for Iron in their fill/auto-fill water, can EASILY do this and not have to pay for testing (and we also know LOTS of people "test' for Iron and get results of 0ppm even though they have Iron in their pool, proven from Vitamin-C testing on the stains they have!) So I feel this test is more accurate than some of the actual iron "testing" done by stores or labs and basically costs *nothing* ... If anyone thinks this iron-test isn't valid please add your input, I'm no science wizard and plenty of smarter people on TFP than I am.

Hope this helps some people.

EDIT: Crud, I can't remember if it was 1TBS or 1TSP that I added. Please note. In hindsight I'm thinking maybe it was a TSP (the smaller amount).