Stenner liquid chlorine pump - How to choose and install

- By Steve_in_C

- Pumps, Filters, and Plumbing

- 222 Replies

CHLORINE (LIQUID CHLORINE OR BLEACH) INJECTION SYSTEM

Overall comment: if you can use a salt water generator (SWG), you should. Bleach is harder to do.

Do you really want to use bleach? Will a SWG (generates bleach in the pool) work for you? If you have a variable speed (VS) pump, then a Stenner injection pump vs a SWG is not a significant economic issue either way. You should stop here and get a SWG. If you loathe hauling bleach, you should get a SWG. If you do not have any DIY abilities, you should get a SWG. There is likely an installer associated with a pool store near you who will come out and install a SWG. Not so with a Stenner. A Stenner injection pump is simple, but may be unknown to the pool store installer. A plumber could likely install it. If your municipality has restrictions on the discharge of salt water, or you don't have anywhere to discharge it you may want to go with a liquid chlorine injection system. The discharge of salt water can kill your grass or injure plants http://hort.cornell.edu/gardening/soil/salts.pdf If you have concerns over corrosion, you may want a bleach injection system.

After reading the above, if a liquid chlorine injection pump is for you, read on. Carefully consider the specifics of your situation.

Choosing pump

Most think that a peristaltic pump such as Stenner is the most reliable means to inject daily bleach. To correctly size, use Pool Math to calculate the volume of bleach needed to raise your FC by 3ppm. You want to add this within 4 hours or less or you will may have to run your main pool pump too long. (This is not an issue with a VS pump).

Example: 20,000-gallon pool, 3ppm is 125 oz 6% bleach. You would need to be able to pump ¼ of the bleach in 1 hour. That would make 31.25 oz per hour, 750 oz per day, or 5.85 gallons per day for 6% bleach. Using the links at the bottom from Stenner, choose a pump and tube combination that delivers 5.85 gallons per day (GPD) or more. In this example you could use the 45MFL2 pump which delivers 10 GPD. A digital lamp timer can be used to cut the Stenner pump on and off. This example uses the fixed head Stenner. The adjustable head Stenner will work but makes a loud clicking noise during the cycle and is not recommended. If you have already purchased an adjustable head pump, you may turn it all the way up to stop the clicking noise. You could choose the 45 series, the 85 series, Econ T, 25, 80, or 100 PSI: all will work.

Choosing timer

Choose a digital timer with 3 prongs (grounded). This timer should be programmable to the minute AND have a battery backup. Many of these timers have an internal battery backup and do not use replaceable batteries. These are often found as "lamp timers".

Choosing tank

A larger tank will store more chlorine and reduce your space requirement for bleach inventory. It's very nice to have a tank large enough to store a month's worth of bleach. A plastic barrel might work. The Stenner pump and tank combination units are very nice and the 30 gallon tank will fulfill the requirements for most residential pool owners. At the time of this writing, a Stenner pump with a 30 gallon tank, tubing, weighted strainer, and injection fitting could be purchased for under $400 including shipping.

Installation

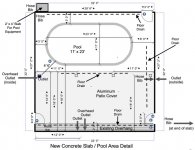

Install your Stenner to pump bleach out of a tank. You should set up the tank in a cool and darkened area to prevent chlorine breakdown while the bleach is stored in the tank. An opaque tank will also help. The bleach tank must be vented (a tank from Stenner is already vented) with at least a small hole somewhere to prevent air lock. Use a Stenner weighted suction line strainer 3” off the bottom of your tank to prevent suctioning sediment. A Stenner injection fitting or a Stenner check valve should be used to inject the bleach into your plumbing circuit after the pump, filter, and heater. If you get the Stenner Check Valve injection fitting, you may remove the duckbill (check valve) as it is not necessary for the lower pressures of a pool system. I have discussed this directly with Stenner Pump technical support. They tell me that the check valve is not a necessity. Pool pressures are highest between the pump and filter. You can read this pressure off of your gauge. After the filter the pressure is less. At the point of injection the pressure should be less than 10 PSI. The liquid chlorine should be pumped in right before the water returns to the pool. You can put in a fitting such as a 2" slip x 1/4" female pipe threat x 2" slip Tee, install a PVC saddle such as "Pentair 2" Saddle Clamp Kit 521512", or use a 1/4" pipe tap to cut threads directly into PVC pipe or fitting (most pools will use either 1.5" or 2" PVC). If you cut threads or "tap" your PVC pipe or fitting to install the Stenner injection fitting DO NOT overtighten as you may crack the PVC pipe. Pipe threads are tapered and have a larger diameter the more you screw them in. Set the Stenner pump to run only when the main pool pump is running. Otherwise, the bleach may run back towards your heater/pump/etc.

Calibration

Before calibration, make sure your pool is "holding chlorine". This means that there is nothing alive in your pool that is consuming chlorine. After dark check your chlorine twice a couple of hours apart. If the chlorine level is not dropping, you are OK. A pool that needs to be slammed will use chlorine (in absence of sunlight) and your calibration will be inaccurate. Calibrate your Stenner pump set up by agitating your pool water and checking the FC after dark. In this manner there will be no breakdown of chlorine by the sun. If your test kit allows, use the larger sample size for improved accuracy. Run the Stenner pump for 60 minutes and stop. Allow the water to agitate for another 15 minutes or more and retest. This is how much FC your pump will add in 60 minutes. Divide 60 minutes by your change in FC and you will tell you how many minutes it takes to add 1ppm to your pool. You will have 1ppm=X minutes. You can now adjust your Stenner pump to add 1X (1ppm), 1.5X (1.5ppm), 2X (2ppm) etc. This will tell you how many minutes to put on your Stenner pump timer based on your FC demands. This is usually 1-3 ppm.

Example: Stenner pump runs for 60 minutes, FC goes from 3.8ppm to 5.0ppm. This gives a FC change of 1.2ppm.

1.2 ppm = 60min; divide both sides by 1.2 and you have 1ppm = 50 minutes. You’d run your pump 50 min for 1ppm, 75 min for 1.5ppm, 100 min for 2ppm, 125 min for 2.5 ppm, or 150 min for 3ppm.

Once your Stenner is calibrated, if you change bleach concentration, you can use the following formula: old run time x old concentration/new concentration = new run time

Example: Old run time: 1ppm=50min (6% bleach). Now you now have 8.25% bleach. 50min x 6/8.25 = 36min. Your new values: 1ppm=36min

Bleach choice

Bleach degrades fast. Factors affecting degradation are concentration (lower is better) , temperature (lower is better), pH (higher is better) , and light (darkness is best). Bleach half life at 90 degrees F: 15% - 48 days, 10% - 115 days, 5% - 371 days. The commonly available 6% has a relatively long half life. If buying 10% / 12.5%, you'd better check the birthday of your bleach. Choose plain beach, no scent, splashless, etc. Order bleach if necessary so that you don't have to buy frequently. It's not economical to drive around hunting for cheap bleach. Bleach still in the boxes that has not been unpacked stacks much better than jugs. Most bleach has a date of manufacture as a Julian date embedded in a number on the bleach jug. Julian date calendar: Julian Day Calendar

COVID update : I changed to bulk beach because of shortages. You can sometimes buy from a pressure washer or janitorial supply. Price in 2020 was $129/55 gallon barrel. 2023-2025 price $195/55 gallon barrel. This bleach is advertised as 12.5% but is often closer to 15% when I get it. I cut in half with water on day 1 because weaker is more stable. 4 grams of lye added to 1/2 barrel to raise pH of my fill water to 11 (also more stable).

https://www.landanc.com/wp-content/uploads/2023/07/2023-Chemical-sheet-04-03-23.pdf Bleach is on the bottom of page 2

Barrel pump: $33

You may test the bleach by using 0.1mL of the unknown bleach concentration in 1 liter of nonchlorinated water (do not use tap water if chlorinated). Agitate and test this with your pool test kit. The chlorine value you obtain is your bleach percentage.

Testing the chlorine percentage of your bleach

The barrel pump tubing is used in respiratory applications. You can find it on Amazon as "aerosol tubing" and use a piece of 1/2" PVC as an inside coupling to connect the tubing together. Make it as long as you need. Just remember that is is a siphon situation and the liquid must flow to lower level.

https://www.amazon.com/1-Pack-Westmed-Corrugated-Aerosol-Tubing/dp/B087JFR6LK/ref=sr_1_4?crid=23AX9GFVKMQT0&keywords=aerosol+tubing&qid=1687699218&sprefix=aerosol+tubing,aps,77&sr=8-4

Wiring

You may have your Stenner pump come on at the same time as your pump with synchronized timers, flow switches, pressure switches, or current sensing from your pool circuit, etc. The idea is for the Stenner pump to only be able to run when the pool pump is running.

Advantages over SWG

Pump run times (and electricity costs) less that required for SWG (8 hours of unnecessary run time per day with a 1500 watt pump at 13cent/kwh is $47/month); this disadvantage is significantly reduced or even erased if you have a VS pump

Can operate in low temperatures (not much of advantage)

More customizable: may mimic manual dosing, SWG slow dosing, or pulse dose multiple times per day.

Less salt to discharge when draining pool. Discharge of high salt pool water may be an issue with a SWG. This depends on your situation. Water with high salt content can kill plants / lawn, some municipalities have codes concerning salt water discharge.

May run VS pump at lowest setting and still inject bleach.

Disadvantages over SWG

Takes some do it yourself (DIY) ability to install .

Must shop/haul/store bleach and recycle jugs (THIS IS THE GREATEST DISADVANTAGE BY FAR)

Annual maintenance once a season (relatively easy), but you have to perform some maintenance on a SWG as well.

Must purchase weak bleach (6%) or keep up with age of bleach due to concerns over degradation for stronger (10-12.5%) bleach.

Requires space to set up bleach tank and to store bleach inventory.

Stenner maintenance (many YouTube videos)

Need to change pump tube annually. Apply Aquashield grease to bushing annually when changing tube.

Cut off 1/2" of tube and replace ferrules on any connecting nut you loosen. Only hand tighten tubing connection nuts.

Need to change sun exposed connecting nuts which break down in sunlight annually (or prevent by covering with foil)

Change all tubing every 2 years.

Parts required with Stenner part numbers

Stenner pump of correct size, ¼” connecting nuts UCAK100, ¼” ferrules UCAK200, ¼” tubing AK4010B, ¼” weighted strainer ST114, ¼” injection fitting CVIJ1/4, bleach tank with 1 month’s capacity, and grounded 3-prong digital lamp timer (adjustable to the minute and not necessary with Econ T Series). Plumbing fittings to allow injection check valve to screw into your plumbing right before water returns to pool.

Stenner Classic fixed head pumps

https://stenner.com/products/pumps/single-head-fixed-output-injection-pump/#boxtab4

Stenner Econ T series pumps

Stenner pumps Econ T programmable automatic timed dosing on a schedule

Stenner has good technical support

[email protected]

(800) 683-2378, (904) 641-1666

eBay often has pumps, both new and used as well as parts.

JULY 2018, with many edits since then.

Overall comment: if you can use a salt water generator (SWG), you should. Bleach is harder to do.

Do you really want to use bleach? Will a SWG (generates bleach in the pool) work for you? If you have a variable speed (VS) pump, then a Stenner injection pump vs a SWG is not a significant economic issue either way. You should stop here and get a SWG. If you loathe hauling bleach, you should get a SWG. If you do not have any DIY abilities, you should get a SWG. There is likely an installer associated with a pool store near you who will come out and install a SWG. Not so with a Stenner. A Stenner injection pump is simple, but may be unknown to the pool store installer. A plumber could likely install it. If your municipality has restrictions on the discharge of salt water, or you don't have anywhere to discharge it you may want to go with a liquid chlorine injection system. The discharge of salt water can kill your grass or injure plants http://hort.cornell.edu/gardening/soil/salts.pdf If you have concerns over corrosion, you may want a bleach injection system.

After reading the above, if a liquid chlorine injection pump is for you, read on. Carefully consider the specifics of your situation.

Choosing pump

Most think that a peristaltic pump such as Stenner is the most reliable means to inject daily bleach. To correctly size, use Pool Math to calculate the volume of bleach needed to raise your FC by 3ppm. You want to add this within 4 hours or less or you will may have to run your main pool pump too long. (This is not an issue with a VS pump).

Example: 20,000-gallon pool, 3ppm is 125 oz 6% bleach. You would need to be able to pump ¼ of the bleach in 1 hour. That would make 31.25 oz per hour, 750 oz per day, or 5.85 gallons per day for 6% bleach. Using the links at the bottom from Stenner, choose a pump and tube combination that delivers 5.85 gallons per day (GPD) or more. In this example you could use the 45MFL2 pump which delivers 10 GPD. A digital lamp timer can be used to cut the Stenner pump on and off. This example uses the fixed head Stenner. The adjustable head Stenner will work but makes a loud clicking noise during the cycle and is not recommended. If you have already purchased an adjustable head pump, you may turn it all the way up to stop the clicking noise. You could choose the 45 series, the 85 series, Econ T, 25, 80, or 100 PSI: all will work.

Choosing timer

Choose a digital timer with 3 prongs (grounded). This timer should be programmable to the minute AND have a battery backup. Many of these timers have an internal battery backup and do not use replaceable batteries. These are often found as "lamp timers".

Choosing tank

A larger tank will store more chlorine and reduce your space requirement for bleach inventory. It's very nice to have a tank large enough to store a month's worth of bleach. A plastic barrel might work. The Stenner pump and tank combination units are very nice and the 30 gallon tank will fulfill the requirements for most residential pool owners. At the time of this writing, a Stenner pump with a 30 gallon tank, tubing, weighted strainer, and injection fitting could be purchased for under $400 including shipping.

Installation

Install your Stenner to pump bleach out of a tank. You should set up the tank in a cool and darkened area to prevent chlorine breakdown while the bleach is stored in the tank. An opaque tank will also help. The bleach tank must be vented (a tank from Stenner is already vented) with at least a small hole somewhere to prevent air lock. Use a Stenner weighted suction line strainer 3” off the bottom of your tank to prevent suctioning sediment. A Stenner injection fitting or a Stenner check valve should be used to inject the bleach into your plumbing circuit after the pump, filter, and heater. If you get the Stenner Check Valve injection fitting, you may remove the duckbill (check valve) as it is not necessary for the lower pressures of a pool system. I have discussed this directly with Stenner Pump technical support. They tell me that the check valve is not a necessity. Pool pressures are highest between the pump and filter. You can read this pressure off of your gauge. After the filter the pressure is less. At the point of injection the pressure should be less than 10 PSI. The liquid chlorine should be pumped in right before the water returns to the pool. You can put in a fitting such as a 2" slip x 1/4" female pipe threat x 2" slip Tee, install a PVC saddle such as "Pentair 2" Saddle Clamp Kit 521512", or use a 1/4" pipe tap to cut threads directly into PVC pipe or fitting (most pools will use either 1.5" or 2" PVC). If you cut threads or "tap" your PVC pipe or fitting to install the Stenner injection fitting DO NOT overtighten as you may crack the PVC pipe. Pipe threads are tapered and have a larger diameter the more you screw them in. Set the Stenner pump to run only when the main pool pump is running. Otherwise, the bleach may run back towards your heater/pump/etc.

Calibration

Before calibration, make sure your pool is "holding chlorine". This means that there is nothing alive in your pool that is consuming chlorine. After dark check your chlorine twice a couple of hours apart. If the chlorine level is not dropping, you are OK. A pool that needs to be slammed will use chlorine (in absence of sunlight) and your calibration will be inaccurate. Calibrate your Stenner pump set up by agitating your pool water and checking the FC after dark. In this manner there will be no breakdown of chlorine by the sun. If your test kit allows, use the larger sample size for improved accuracy. Run the Stenner pump for 60 minutes and stop. Allow the water to agitate for another 15 minutes or more and retest. This is how much FC your pump will add in 60 minutes. Divide 60 minutes by your change in FC and you will tell you how many minutes it takes to add 1ppm to your pool. You will have 1ppm=X minutes. You can now adjust your Stenner pump to add 1X (1ppm), 1.5X (1.5ppm), 2X (2ppm) etc. This will tell you how many minutes to put on your Stenner pump timer based on your FC demands. This is usually 1-3 ppm.

Example: Stenner pump runs for 60 minutes, FC goes from 3.8ppm to 5.0ppm. This gives a FC change of 1.2ppm.

1.2 ppm = 60min; divide both sides by 1.2 and you have 1ppm = 50 minutes. You’d run your pump 50 min for 1ppm, 75 min for 1.5ppm, 100 min for 2ppm, 125 min for 2.5 ppm, or 150 min for 3ppm.

Once your Stenner is calibrated, if you change bleach concentration, you can use the following formula: old run time x old concentration/new concentration = new run time

Example: Old run time: 1ppm=50min (6% bleach). Now you now have 8.25% bleach. 50min x 6/8.25 = 36min. Your new values: 1ppm=36min

Bleach choice

Bleach degrades fast. Factors affecting degradation are concentration (lower is better) , temperature (lower is better), pH (higher is better) , and light (darkness is best). Bleach half life at 90 degrees F: 15% - 48 days, 10% - 115 days, 5% - 371 days. The commonly available 6% has a relatively long half life. If buying 10% / 12.5%, you'd better check the birthday of your bleach. Choose plain beach, no scent, splashless, etc. Order bleach if necessary so that you don't have to buy frequently. It's not economical to drive around hunting for cheap bleach. Bleach still in the boxes that has not been unpacked stacks much better than jugs. Most bleach has a date of manufacture as a Julian date embedded in a number on the bleach jug. Julian date calendar: Julian Day Calendar

COVID update : I changed to bulk beach because of shortages. You can sometimes buy from a pressure washer or janitorial supply. Price in 2020 was $129/55 gallon barrel. 2023-2025 price $195/55 gallon barrel. This bleach is advertised as 12.5% but is often closer to 15% when I get it. I cut in half with water on day 1 because weaker is more stable. 4 grams of lye added to 1/2 barrel to raise pH of my fill water to 11 (also more stable).

https://www.landanc.com/wp-content/uploads/2023/07/2023-Chemical-sheet-04-03-23.pdf Bleach is on the bottom of page 2

Barrel pump: $33

You may test the bleach by using 0.1mL of the unknown bleach concentration in 1 liter of nonchlorinated water (do not use tap water if chlorinated). Agitate and test this with your pool test kit. The chlorine value you obtain is your bleach percentage.

Testing the chlorine percentage of your bleach

The barrel pump tubing is used in respiratory applications. You can find it on Amazon as "aerosol tubing" and use a piece of 1/2" PVC as an inside coupling to connect the tubing together. Make it as long as you need. Just remember that is is a siphon situation and the liquid must flow to lower level.

https://www.amazon.com/1-Pack-Westmed-Corrugated-Aerosol-Tubing/dp/B087JFR6LK/ref=sr_1_4?crid=23AX9GFVKMQT0&keywords=aerosol+tubing&qid=1687699218&sprefix=aerosol+tubing,aps,77&sr=8-4

Wiring

You may have your Stenner pump come on at the same time as your pump with synchronized timers, flow switches, pressure switches, or current sensing from your pool circuit, etc. The idea is for the Stenner pump to only be able to run when the pool pump is running.

Advantages over SWG

Pump run times (and electricity costs) less that required for SWG (8 hours of unnecessary run time per day with a 1500 watt pump at 13cent/kwh is $47/month); this disadvantage is significantly reduced or even erased if you have a VS pump

Can operate in low temperatures (not much of advantage)

More customizable: may mimic manual dosing, SWG slow dosing, or pulse dose multiple times per day.

Less salt to discharge when draining pool. Discharge of high salt pool water may be an issue with a SWG. This depends on your situation. Water with high salt content can kill plants / lawn, some municipalities have codes concerning salt water discharge.

May run VS pump at lowest setting and still inject bleach.

Disadvantages over SWG

Takes some do it yourself (DIY) ability to install .

Must shop/haul/store bleach and recycle jugs (THIS IS THE GREATEST DISADVANTAGE BY FAR)

Annual maintenance once a season (relatively easy), but you have to perform some maintenance on a SWG as well.

Must purchase weak bleach (6%) or keep up with age of bleach due to concerns over degradation for stronger (10-12.5%) bleach.

Requires space to set up bleach tank and to store bleach inventory.

Stenner maintenance (many YouTube videos)

Need to change pump tube annually. Apply Aquashield grease to bushing annually when changing tube.

Cut off 1/2" of tube and replace ferrules on any connecting nut you loosen. Only hand tighten tubing connection nuts.

Need to change sun exposed connecting nuts which break down in sunlight annually (or prevent by covering with foil)

Change all tubing every 2 years.

Parts required with Stenner part numbers

Stenner pump of correct size, ¼” connecting nuts UCAK100, ¼” ferrules UCAK200, ¼” tubing AK4010B, ¼” weighted strainer ST114, ¼” injection fitting CVIJ1/4, bleach tank with 1 month’s capacity, and grounded 3-prong digital lamp timer (adjustable to the minute and not necessary with Econ T Series). Plumbing fittings to allow injection check valve to screw into your plumbing right before water returns to pool.

Stenner Classic fixed head pumps

https://stenner.com/products/pumps/single-head-fixed-output-injection-pump/#boxtab4

Stenner Econ T series pumps

Stenner pumps Econ T programmable automatic timed dosing on a schedule

Stenner has good technical support

[email protected]

(800) 683-2378, (904) 641-1666

eBay often has pumps, both new and used as well as parts.

JULY 2018, with many edits since then.