Plaster Discolorations – New white pool plaster can discolor (darken or turn gray) from adding excessive calcium chloride set accelerator, from late hard troweling, from thin and thick areas due to an uneven shell, etc. Gray (or grey) mottled discoloration (also known as “water entrapment” or “hydration”) is smooth to the touch and difficult to lighten, may be remedied by acid washing, sanding, or torching the surface, but these processes are generally detrimental to a plaster finish and the discoloration often returns later. Late hard troweling can cause “trowel burn” which darkens the plaster color in localized areas. Severe mottled color variation from calcium chloride or finishing issues may occur quickly once filled with water, or take several months to become visible.

See these threads:

How White Pool Plaster Can Turn Gray

How White Pool Plaster Turns Blotchy

Gray Mottling Plaster Discoloration

White Spotting and Streaking – New Plaster (white or dark colored) may develop smooth white (lighter color) porous (soft) spots and streaks (sometimes incorrectly termed as “spot etching”) resulting from the addition of water to the hardened surface during late hard troweling in plaster containing excessive calcium chloride. This late hard troweling disturbs surface aggregate, and added water penetrates around that aggregate and spreads laterally through the porous paste caused by accelerated shrinkage. Beginning as excess porosity around the disturbed aggregate, soft spots expand and sometimes coalesce into larger affected areas as cement components are dissolved away over time. Disturbed zones along accent or surface tile, around fittings, etc. may also display this non-removable deterioration. This type of problem usually takes several months to show up.

See this thread:

White Spotting of New Plaster Pools

Whitened Discoloration of Colored Plaster – In time, integrally dark colored pool plaster may begin to show whitening (lighter color) either uniformly or in patterns. Uniform discoloration may be caused by using incompatible admixtures: specifically color pigments and calcium chloride. "Organic" and "Blue" pigments are prone to become bleached out by chlorine, and should not be used in pool plaster applications. These colored plasters may also be discolored (white streaking or spotting) from the addition of water to the surface or to trowels applied to the surface during finishing. These discolorations are permanent, unless major sanding is performed. White discoloration may be calcium scale developing due to imbalanced water, such as high CH, high TA, and overly high pH. Fortunately, the white scale can be removed by either sanding or an acid treatment.

See this thread:

White Spotting of New Plaster Pools

Spalling – Spalling is the flaking or peeling of a thin layer (1/8 inch or less) of plaster, usually in small areas on steps and shallow end floors. It is caused by the over-troweling of the surface when the underlying paste is wet but the surface cement laitance is dry. It can also be caused by adding too much water while troweling. This usually results from improperly timed troweling, or from hot, windy or dry days. When water evaporates from the surface faster than mix water bleeding up can replace it, and then when that surface dry crust is troweled, a weakened subsurface zone is created that will be prone to spall. Spalling may occur immediately, or years later when the pool is drained, etc. Spalls may be sanded, although the pool may need to be replastered if large areas have spalled.

Delaminations – This is the separation of an entire new layer of plaster from its underlying substrate, whether that is old plaster, gunite or shotcrete, etc. Delaminations are usually first seen as a round surface area that has raised or pulled away from the wall, often with small cracks and nodules forming. This defect is usually caused by improper surface preparation to create a good bond during a replaster. It may manifest itself within a month or two or several years later when the pool is drained and the plaster dries out. Ground movement such as during earthquakes, can also initiate bond failure. Occasionally, some plaster areas completely pop off, exposing the underlying surface. Delaminated areas may be patched if small, but larger delaminations require replastering.

See this thread:

Calcium Nodules in pools

Calcium Nodules – Nodule spots are a raised and rough form of calcium efflorescence that sporadically forms on a plaster surface. Nodules may be circular volcano-type formations or stalactite-like drips down the plaster wall. They are most often associated with plaster delaminations (as mentioned above), or with severe craze cracks, either of which allow balanced water to penetrate the surface and dissolve and bring calcium from the interior to the exterior of the pool plaster layer. Nodules may be removed by sanding or scraping, but generally continue to form again and again. See this thread:

Calcium Nodules in pools

Craze Cracks – Crazing is an excessive amount of surface shrinkage cracking which can result from an overly-wet plaster mix, from excessive calcium chloride set accelerator added to the mix, from the adding of excessive water while troweling, or from excessive drying of the plaster before the pool is filled. Crazing often leads to other problems including calcium nodules, staining, and provide a home to black algae. Excessive crazing may require replastering.

Identifying Curing Effects on New Pool Plaster - Newly plastered pools must be filled at the right time, and any water exposure must be even and uniform. Filling a pool too early can result in a weakened and deteriorated paste surface, especially in the bowl of the pool where the effect is worse because it may be exposed to fill water mere minutes after final troweling. The optimum fill delay (time between final troweling and filling the pool) is at least six or more hours. (Moderate temperatures and sufficient humidity is also necessary for proper hardening and curing of plaster). This fill delay is often realized for the upper half of the pool, which may not be submerged for a day or longer depending on water pressure, while some plastering crews start the fill before they leave and thus compromise the lower areas of the pool.

Wetting of parts of the surface by rinsing down the deck, rinsing off pool steps or areas where debris falls, etc. must also be avoided, since the uneven exposure of fresh plaster to water makes permanent discoloration. The fill must also be continual – pauses in the fill may result in “bathtub ring” permanent discoloration.

Staining – Fill water containing excessive levels of iron, copper, or other metals can cause various colors of staining and should be filtered and removed, or at least treated before the pool is filled, or, if that is not possible, immediately upon filling the pool to the surface tile level. This kind of staining can usually be removed by acid washing, sanding or chelation. Some of these techniques are invasive to the surface, and avoiding staining is better than removing it later.

Scale or Etching from Improper Chemical Addition – Pool chemicals need to be added to the water in a manner that prevents aggressive/scaling amounts of chemical or imbalanced water from affecting the new plaster surface. Acid should always be pre-diluted before adding, salt should only be added after 30 days of plastering, and should not be allowed to sit as a solid on fresh plaster. Cyanuric acid and soda ash must also not sit as a solid on new plaster.

Water Balance, Scaling and Etching - Before filling a new plaster pool, the chemistry of the fill water should be determined. Tap water that is too soft (aggressive) can create plaster dust, and etch or weaken the new plaster surface, and should be balanced before filling. Of course, once the pool is filled, the Saturation Index (or CSI) provides an excellent guide for maintaining pool water in a manner which will minimize detrimental effects to the new plaster surface. Scaling is caused by overly scale forming (high positive CSI) water. Sanding or an acid treatment usually removes the white scale.

Etching (from low pH/alkalinity/calcium) and scaling (from high pH/alkalinity/calcium) are uniform effects across the pool surface, unless affected by areas of greater or lesser pool plaster surface porosity. The etching process can create a uniform rough and pitted surface, but does not discolor the plaster. Calcium scale on the surface is also generally rough to the touch, white, and uniform (much like sandpaper). In time, scale or an etched surface will attract dirt and minerals, and discolor. Although stains, dirt, and scale deposits can generally be removed by sanding, acid washing or chelation, etching is permanent and can only be moderately mitigated by sanding the surface.

Acid Start-ups – Swimming pools should never undergo the acid start-up process. Designed as a way to remove plaster dust without filtration, acid start-ups are too aggressive for fresh plaster and will etch the surface. Subjecting fresh plaster to water with a pH below 5 is not an appropriate substitute for doing things right in the first place. This just ages the pool plaster and will likely begin to show dirt and metal staining sooner than usual.

Plaster Dust in New Pools – This is the bleeding (loss) of calcium from a new plaster surface that may be caused by improper plastering practices and/or as a result of filling too soon or with too soft (aggressive) tap water. This dust can harden into a surface calcification and trap dirt or metals, creating further discoloration. Dusting from new pool plaster is preventable by properly mixing, troweling, curing the surface in moderate temperatures and with sufficient humidity, waiting at least six hours before filling, and then ensuring the chemistry of the fill water is balanced before being used to fill the new plaster pool. When necessary, the fill water chemistry should be adjusted by adding sodium bicarbonate, acid, chelating or sequestering agents, etc. through a slurry tank as the pool fills. Although plaster dust can be removed by brushing and filtering, the damage from the calcium loss from the surface creates porosity and is permanent.

Prevention is the key – proper plastering procedures, proper curing, and proper water balance result in a plaster surface that is both maintainable and aesthetically pleasing. Fixing errors after-the-fact is generally less than desirable, and some detrimental effects can only be remedied by replacing the plaster. Quality plaster that is maintained well and in CSI balance will generally last 20 years.

Also see these posts:

Being Blamed for Plaster Discolorations? Don't Get Hoodwinked

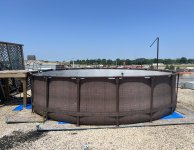

ten-guidelines-for-quality-pool-plaster-t42957.html that I don't know what to do. It has increased from a pin size to a BB size in the past week. There is a soft spot in the metal wall about golf ball size around this hole. The water has went down about 3 inches since last week. Our temps have went back down this week in GA so I haven't got in the pool to patch the hole in the liner. I believe that the hole is directly in same spot as the hole in metal wall as I can stop the water coming out the metal wall if I put the plastic net on opposite side of wall flush with the liner. It is 33 degrees here right now and I am not looking forward to getting into the pool to stop this leak. I bought Boxer patch kit and the Dye leak test kit. I do have a dive suit but I dislike cold temps. Can I drain this pool a little so that I'm not jumping in 4 foot of ice cold water? Please advice of how to fix my leaking pool. What is my first step? Stopping the leak in liner? How do I know if the leak was from the hole in the metal wall or just a tear in liner? I read a similar post and got some ideas as to what could have happened. I just want to fix this properly and not make anything worse.

that I don't know what to do. It has increased from a pin size to a BB size in the past week. There is a soft spot in the metal wall about golf ball size around this hole. The water has went down about 3 inches since last week. Our temps have went back down this week in GA so I haven't got in the pool to patch the hole in the liner. I believe that the hole is directly in same spot as the hole in metal wall as I can stop the water coming out the metal wall if I put the plastic net on opposite side of wall flush with the liner. It is 33 degrees here right now and I am not looking forward to getting into the pool to stop this leak. I bought Boxer patch kit and the Dye leak test kit. I do have a dive suit but I dislike cold temps. Can I drain this pool a little so that I'm not jumping in 4 foot of ice cold water? Please advice of how to fix my leaking pool. What is my first step? Stopping the leak in liner? How do I know if the leak was from the hole in the metal wall or just a tear in liner? I read a similar post and got some ideas as to what could have happened. I just want to fix this properly and not make anything worse.