Update: As I write this, the spa is filling!

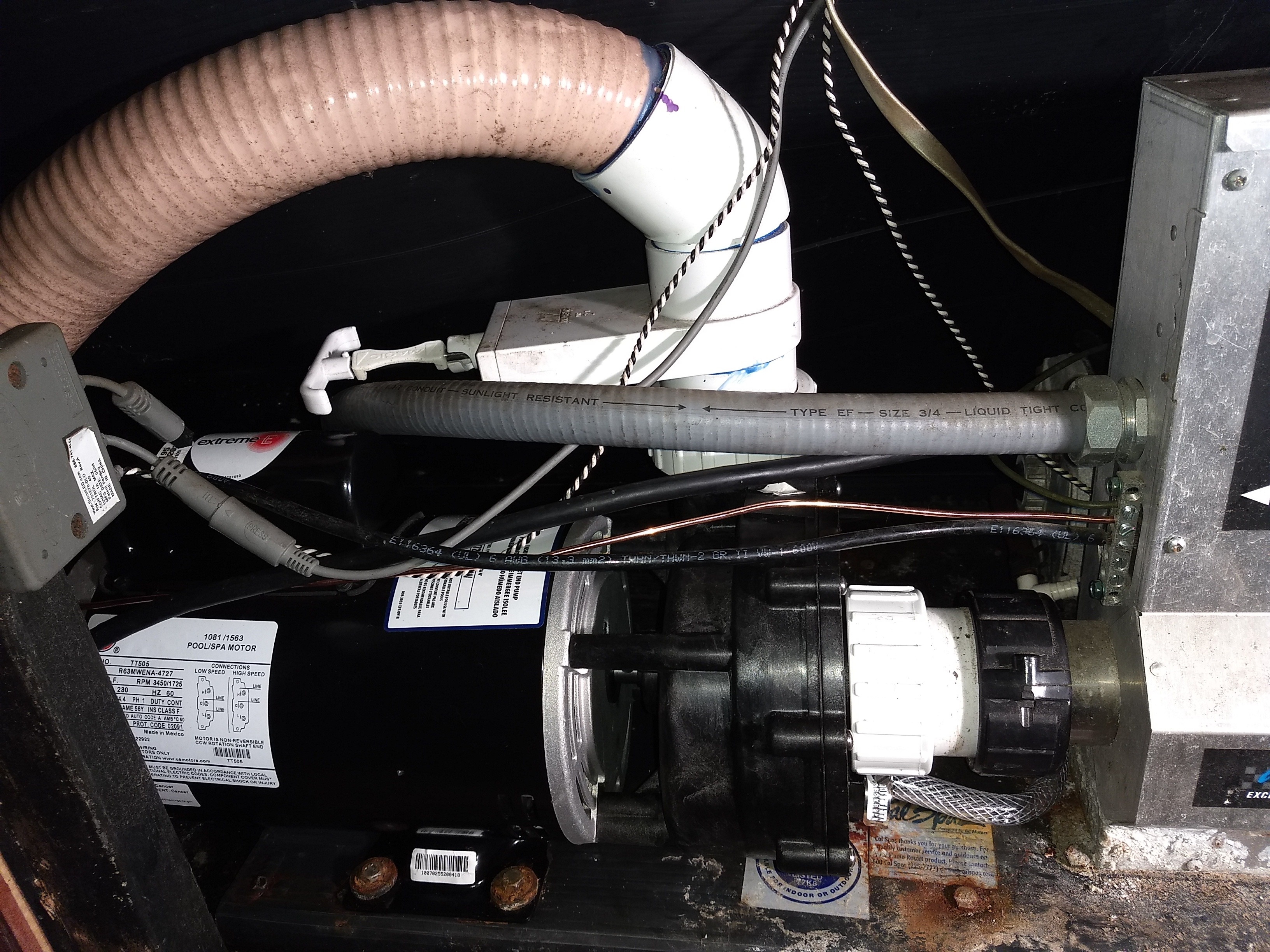

So, the previous lead seemed to be a combination of a thin walled tube and the uneven pressure of a hose clamp. As I didn't have spring clamps handy, I did the next best thing, got hose that was twice as thick as the previously used hose. The idea is the thicker walls allow the uneven hose clamp pressure to spread out and obtain a good seal. Also the new clamps from Home Depot are a lot wider than the dinky ones that came from Spa Depot, hopefully that helps a little as well.

I attached this hose to the tee first, before the pump got in the way.

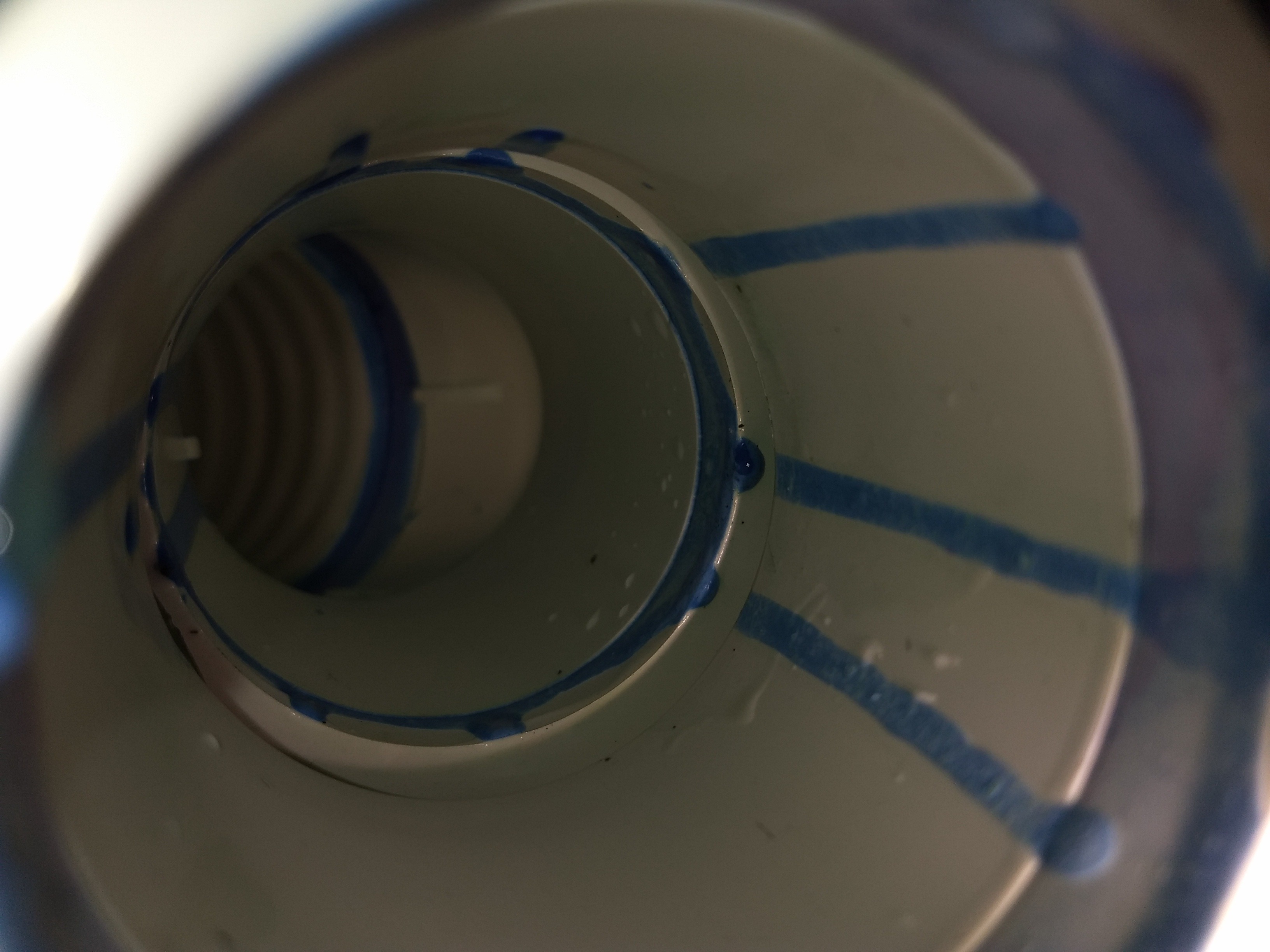

I also took a look at the gate valve, figured out (I think) why the it wouldn't close. There's a hardened drop of glue on one side where the slide needs to go to seal.

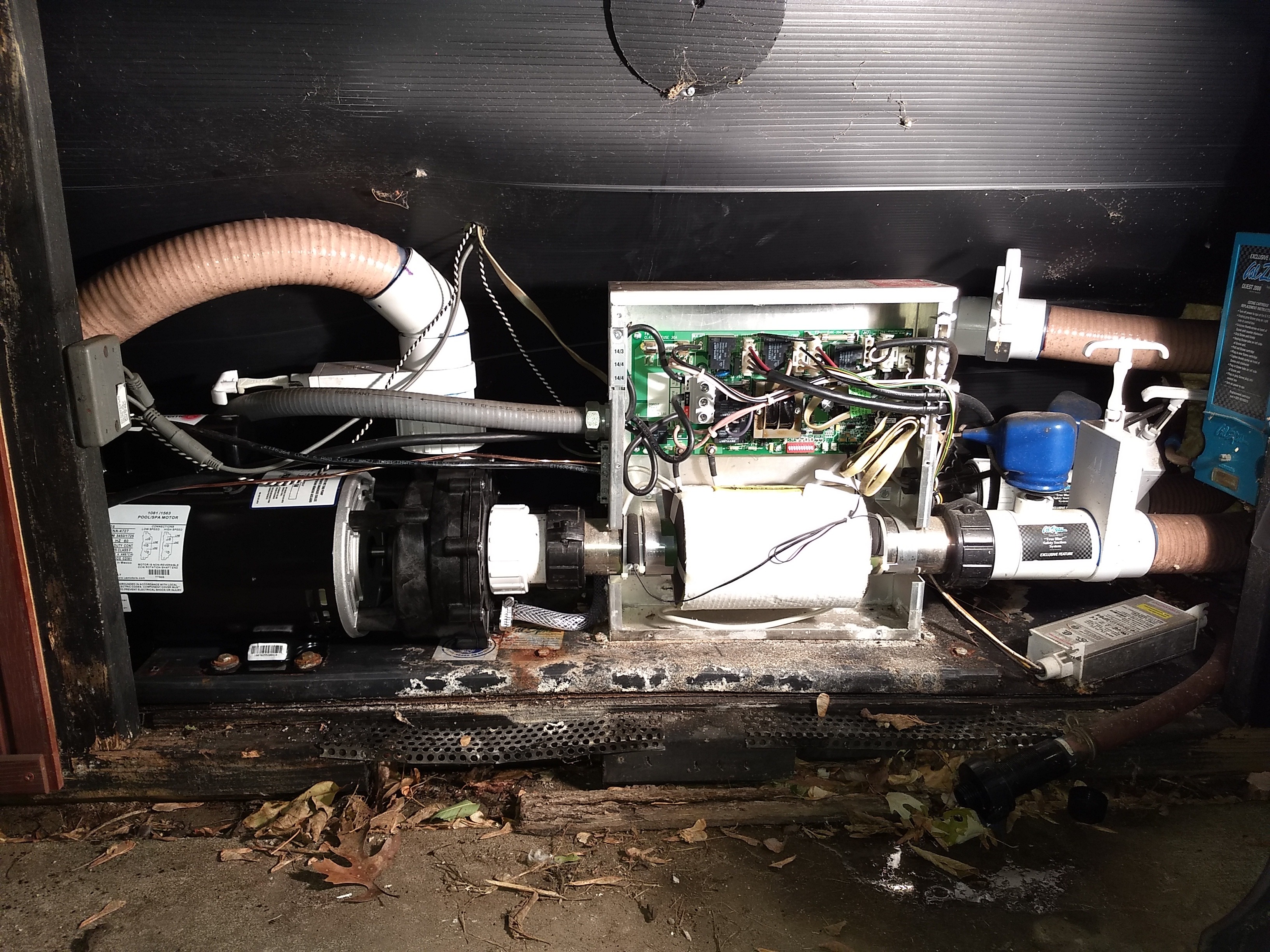

I test fit the pump, all looked good.

While the pump was in place for test fitting, I used a sharpie to outline the new mounting hole locations. After I took this picture I drilled pilot holes for the for mounting bolts.

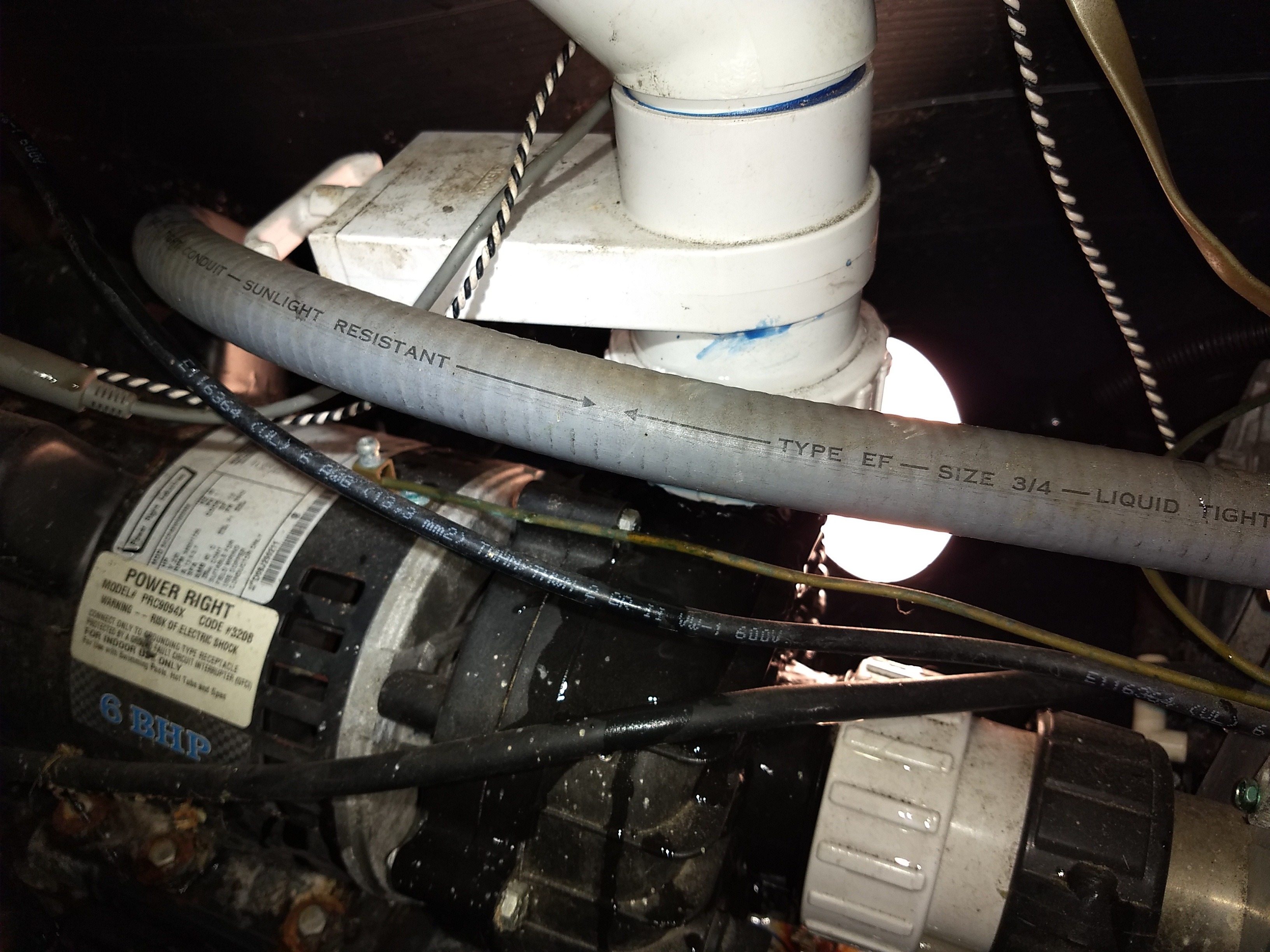

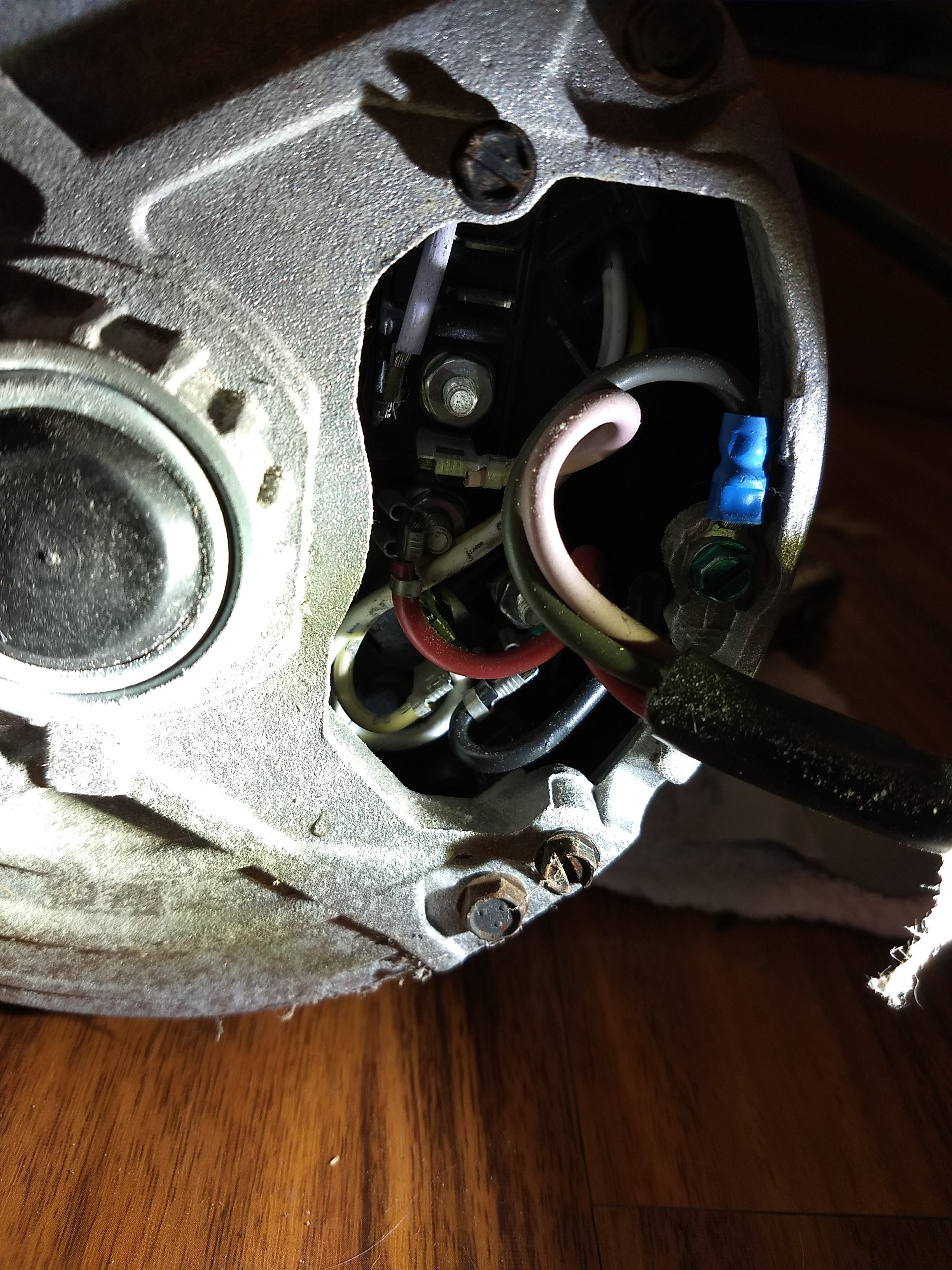

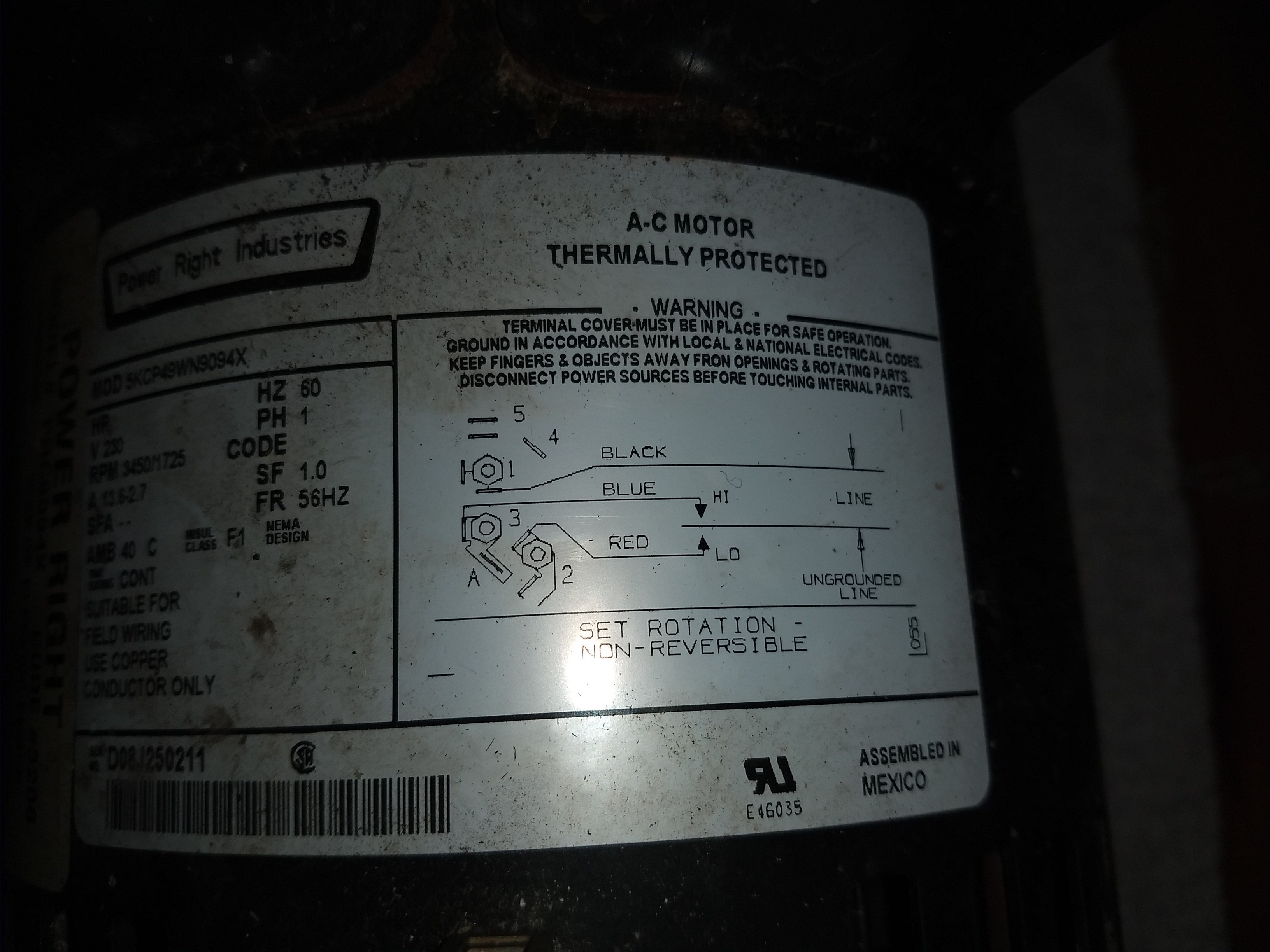

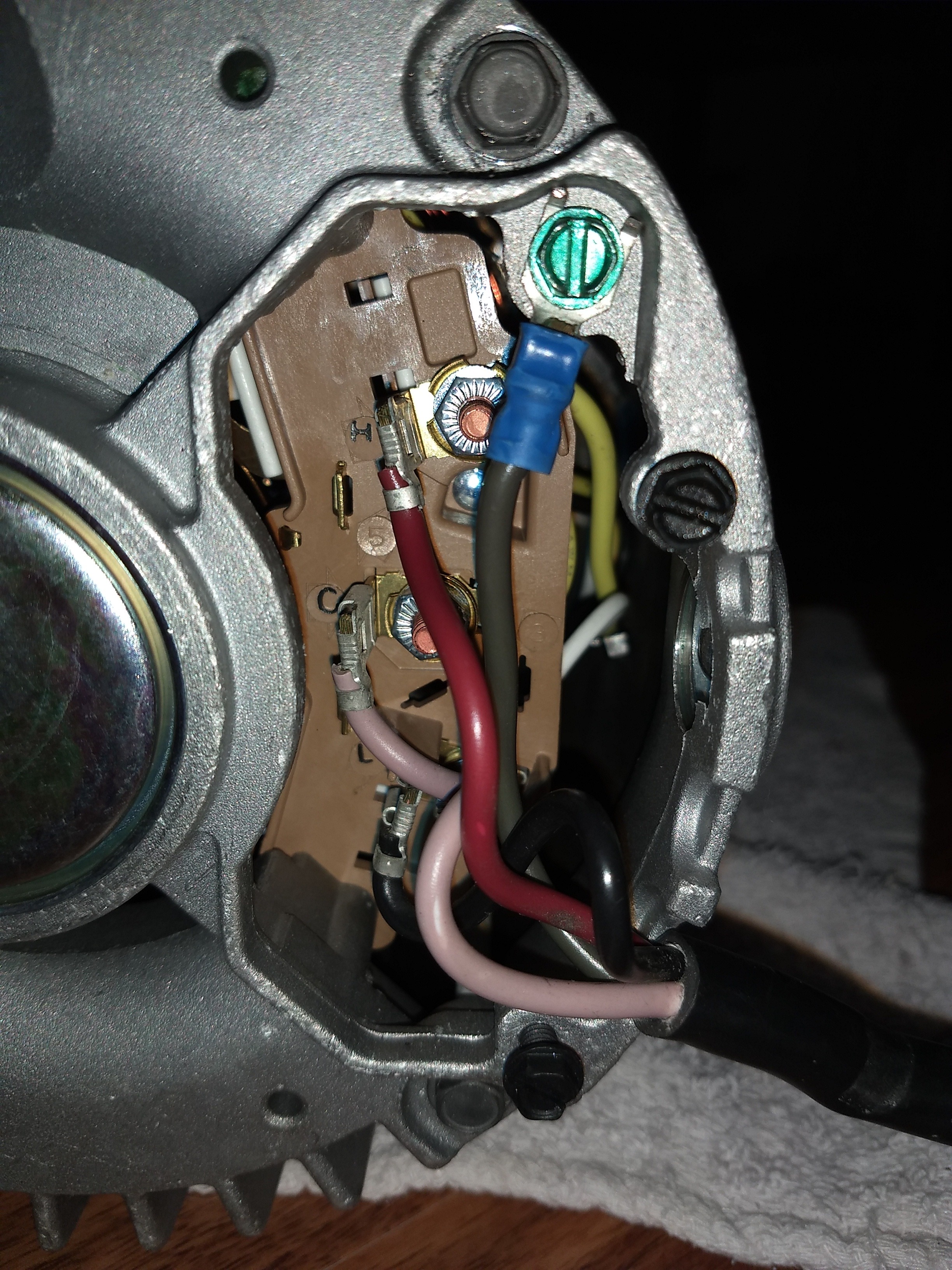

I then had to run to Home Depot as the old equipotential bonding wire was cut for a top mounted terminal on the old motor, and the new motor has the terminal on the back of the motor. This needs to be 8 AWG or larger, and the largest scrap I had laying around was 10 AWG.

I cut a section a bit long on purpose and attached it to the motor.

I then put the pump back in, connected the heater water line, screwed it down, connected the other water line, the equipotential bonding wire, pump power wire, and drain hose. All set for water and testing!

One thing I did note that may be an issue in the future is it seems the glue joint between the hose and elbow is breaking. There's a bit of stress on the hose here, not sure why they didn't do a 90 instead of a 45 here.

Don't forget to close your drain valve before filling!

Anyway, that's the progress so far. If no leaks during filling, then once the spa is filled it's time to flip the disconnect and see if we have leaks under pressure. Hopefully all is good, if so it's water balance time and we'll be enjoying this tomorrow evening!

Keen readers may note I did NOT change the valve that wouldn't shut, I didn't get a new one ordered. Hopefully everything is wired up right and works! I will order one here shortly, to have on hand, and next time I need to drain and do maintenance I'll put the new valve in.

(great warnings in place=

(great warnings in place= )

)