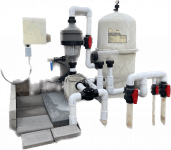

Please Review my plumbing before I glue

- Thread starter Nochain

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Jun 24, 2021

- 7,654

- Pool Size

- 30000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60

@Nochain I don't know what is glued and what is not. I would remove and replace the PVC valves with never-lube (like you have on the suction side). The PVC valves will lock up over time. Never-lubes can be rebuilt. Sucks to cut them out and replace when they do fail. Better to do it now. Ask me how I know.

Oh and I have one question. The 220V line comming in has a conduit gnd clamp with the wire all curled up in the picture. Should that be connected to a ground rod? If so how long does that rod need to be?

- Jun 24, 2021

- 7,654

- Pool Size

- 30000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60

Thanks I was thinking about that and tried to be cheap. Hearing your inpul I’ll bite the bullet and get a Jandy.@Nochain I don't know what is glued and what is not. I would remove and replace the PVC valves with never-lube (like you have on the suction side). The PVC valves will lock up over time. Never-lubes can be rebuilt. Sucks to cut them out and replace when they do fail. Better to do it now. Ask me how I know.

Thanks!

- Jun 24, 2021

- 7,654

- Pool Size

- 30000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60

"a" jandy? You have 4 PVC valves in the picture...get a Jandy

To be able to back wash the cyclone filter easier. It was in the instructions.@Nochain Why do you have a valve between the pump and the filter?

The three on the outlet side are legacy. I also never use them. I might change those in the future."a" jandy? You have 4 PVC valves in the picture...

- Jun 24, 2021

- 7,654

- Pool Size

- 30000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60

You must use them...they are turned off...I also never use them. I might change those in the future.

Not a big deal as that section has unions and can be remade fairly easily. However, I like to avoid remaking thing.Hearing your inpul I’ll bite the bullet and get a Jandy.

What type of valves should be used on the outlet side? Looks like a 3/4” and 1.5” pipe? Maybe I’ll redo those as well. Just not sure what to use.

- Jun 24, 2021

- 7,654

- Pool Size

- 30000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60

For the 1.5": (not recommending poolzoom, just showing the valve.What type of valves should be used on the outlet side? Looks like a 3/4” and 1.5” pipe? Maybe I’ll redo those as well. Just not sure what to use.

2 Port Neverlube Valve, 1-1/2" x 2"

Jandy 2 Port Neverlube Valve. 1-1/2" internal port x 2" external port. Manufacturer Part Number: 4724. We stock replacement parts for all major brands in the pool industry. Flat Rate Shipping!

For the 3/4" you could use a "true union valve," or "double union" valve. the mechanism can then be re-placed if needed.:

Jandy Heavy Duty Double Union Ball Valve | 3/4" PVC | Grey | BVDU008

Pool Supply Unlimited has some of the best prices when shopping for Jandy Heavy Duty Double Union Ball Valve | 3/4" PVC | Grey | BVDU008

Let's ping @ajw22, @JamesW and @Jimrahbe ...they may have better ideas on the 3/4"

- Jun 24, 2021

- 7,654

- Pool Size

- 30000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60

- Feb 6, 2015

- 6,236

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

For the 3/4" valve, these are good...

The Jandy valves are 1.5" inside and 2" outside.

In the AZ heat, the cheap ball valves will seize or break within a few years.

HYDROSEAL Kaplan 3/4" PVC True Union Ball Valve

For the 1.5 inch - with a little plumbing work, you could use a single 3-way Jandy valve instead of two 2-way Jandy valves. Just plumb in the 3/4" valve before the 1.5 inch Jandy.The Jandy valves are 1.5" inside and 2" outside.

In the AZ heat, the cheap ball valves will seize or break within a few years.

Left main output to wall ports. Center is the aerator and the right line is water fall feature that is a mess to use.@Nochain To help, what are your input and output lines going to, left to right?

- Feb 6, 2015

- 6,236

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

Oh and I have one question. The 220V line comming in has a conduit gnd clamp with the wire all curled up in the picture. Should that be connected to a ground rod? If so how long does that rod need to be?

That's a "bonding" wire, not a ground wire. The bonding wire needs to be attached to all your equipment - the pump, Circupool controller box and the timer/sub-panel.

Bonding is the process by which the electrical and metallic components of the pool are joined together with a wire to form a non-resistive path between the components. The goal of bonding is to connect, contain and prevent the transmission of any harmful electrical voltage to pool equipment, people and pets.

Electrical Bonding - Further Reading

Thanks makes sense. Reminds me of solving ground loop issues on HAM equipment.That's a "bonding" wire, not a ground wire. The bonding wire needs to be attached to all your equipment - the pump, Circupool controller box and the timer/sub-panel.

Bonding is the process by which the electrical and metallic components of the pool are joined together with a wire to form a non-resistive path between the components. The goal of bonding is to connect, contain and prevent the transmission of any harmful electrical voltage to pool equipment, people and pets.

Electrical Bonding - Further Reading

www.troublefreepool.com

Ok after taking all your inputs (thank you) and waiting for parts here is my dry (before glue) fitment. Thought I would throw this up before I glue it all together. Let me know if you see anything I need to change from here.

Oh an what is the best procedure for putting the valves together? Ie glue each end then tighten down? Should the rings be loose fit and then glues in on both sides then tightened down? Seems straight forward but sometimes theres a nuance that is needed.

Oh an what is the best procedure for putting the valves together? Ie glue each end then tighten down? Should the rings be loose fit and then glues in on both sides then tightened down? Seems straight forward but sometimes theres a nuance that is needed.

- Jun 24, 2021

- 7,654

- Pool Size

- 30000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60

Totally personal preference, but I would use the double union only on the 3/4 inch and use the neverlubes on the 1.5" connections.

I would connect the aerator before the T.

I would replace the T with a single three way neverlube and eliminate having the two 1.5 ball valves.

I would raise the salt cell so the return from cell to the now 3 way valve only requires two 90s instead of 3.

I would connect the aerator before the T.

I would replace the T with a single three way neverlube and eliminate having the two 1.5 ball valves.

I would raise the salt cell so the return from cell to the now 3 way valve only requires two 90s instead of 3.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.

Similar threads

- Replies

- 6

- Views

- 180

- Replies

- 199

- Views

- 3K

- Replies

- 9

- Views

- 139

- Replies

- 47

- Views

- 1K