- Jul 21, 2013

- 65,634

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

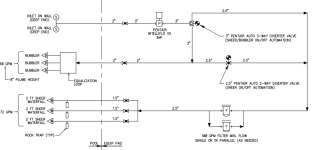

Nope, diverter can be opposite the intake pipe so both output pipes are open.the three way valve is just like the pool/spa three way valve. it only allows water in one of the directions shown with the arrows, right?

View attachment 553354