thanks

@Latitude22 ... i forgot yours were still coming!

hey

@Dirk, on oakwater's unit i'm going to pull the connector, relay and the other dead parts so I can look at the board and try to figure out a little more. I was thinking I'd use wire nuts or a basic "barrier terminal block" or something to keep high currents off the board...

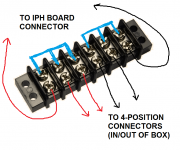

The terminal block idea was to cut the wires off of the connector, attach the 2 red wires coming into the box, and 1 of the red wires from the connector to 3 of the terminals, joining them with a 3-position jumper. Then do the same for the black wires. The red/black wires going to the iph board will occupy one of the un-burned connector positions

That should be fine because it doesn't take much to power the iph board itself... something like this:

View attachment 402650

I don't really think it's any better that just wire-nutting them together... so maybe just do what's easiest? Either way you do it I'm sure it'll void any remaning warranty. But it might be something you just have to do when you install an intellichlor or iph?

Oh, and I'll leave the white/green (data lines) on the connector because they don't seem to cook... which makes sense because there shouldn't be any current on them anyway. What

doesn't make sense is how the data line protection diodes and comm chips are blowing up when there shouldn't be any current.