Can't really tell how fine it adjusts to but I can't see a failure happening! Why don't you try it out and let us know how they work...lol!

Homemade Acid OR Chlorine Injection System

- Thread starter mas985

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Has anyone identified the cheapest source for the 1/4" hayward needle valve? Just opened my pool and since it looks like the feedback on this valve has been positive I need to order one.

Thanks, and good to read everyone again

Thanks, and good to read everyone again

Drillspot has had the best price that I've seen so far on the hayward valves. I found one on ebay last year but not since.

Thanks. I hit ebay before posting here. I figured you got the last one

Looks like drillspot just has the NV and not the NVA. Any difference?

Looks like drillspot just has the NV and not the NVA. Any difference?

Looks like the only difference between the NV & NVA is the pretty red thumbwheel. I bet you get the NVA even though it's not listed.

Bama Rambler said:Looks like the only difference between the NV & NVA is the pretty red thumbwheel. I bet you get the NVA even though it's not listed.

Ordered it yesterday afternoon, using google checkout it took all of 10 seconds. Painless. With free shipping it said it would show up Friday, but it came today, from Grainger.

And it is the NVA with the red thumbwheel. Good call

lborne

0

bobodaclown said:Has anyone tried using a duck bill valve for the check valve. I have a chlorine injector pump on our well (iron bacteria). It allows the chlorine to get injected to the water supply but doesn't allow the water to flow back into the chlorine container. When the valve goes bad it will allow reverse flow. OOPS. But its a 5 minute fix. Info on duck bill valve:http://www.general-rubber.com/flex-valve/styles/4100.html

That is essentially what the aquarium check valve I am using. The spring ones don't last long as the acid eats away the steel, so I went with a duck bill type. Think I got it at wal-mart.

lborne

0

minmex said:Has anyone tried this valve for a chlorine dispensing version?

http://www.usplastic.com/catalog/item.aspx?itemid=23076

It just goes over the tubing. Seems like perhaps two of them in line might work?

I'm using a hard plastic tube since it is all on the suction side, so not sure how well it would work. A pair of vice grips might work just as well

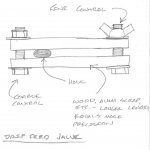

The hose clamping valves mentioned by several posters gave me an idea for making a simple diy / homemade precision valve.

This should cost less than a dollar in materials and take less than 10 minutes to make (if your drill is handy).

Take two pieces of wood... sketching... see attached drawing.

[attachment=0:36k03fhl]drip feed valve.jpg[/attachment:36k03fhl]

The valve is a simple device to pinch the hose. Using 2 bolts, some washers, a nut, a wingnut, and two pieces of wood or aluminum (or strong scrap material).

The hose is set near one end where the bolt is adjusted to make the course adjustment. At the far end, the wingnut makes a fine adjustment. The longer the lever arm, the more precise the adjustment available.

Note: Wood, if not sufficiently thick, may bend over time and require periodic tightening.

Width of the lever may have some effect, but my guess is that whatever point of the tube is pinched the most will be what sets the rate, so width won't matter.

Although I've been reading this thread with interest, I'm still a while from needing to add any chlorine to my pool so this project is a low priority for me. Middle of cold spell here and under my opaque solar cover, my chlorine level keeps holding. So if anyone tries this, please share your results.

This should cost less than a dollar in materials and take less than 10 minutes to make (if your drill is handy).

Take two pieces of wood... sketching... see attached drawing.

[attachment=0:36k03fhl]drip feed valve.jpg[/attachment:36k03fhl]

The valve is a simple device to pinch the hose. Using 2 bolts, some washers, a nut, a wingnut, and two pieces of wood or aluminum (or strong scrap material).

The hose is set near one end where the bolt is adjusted to make the course adjustment. At the far end, the wingnut makes a fine adjustment. The longer the lever arm, the more precise the adjustment available.

Note: Wood, if not sufficiently thick, may bend over time and require periodic tightening.

Width of the lever may have some effect, but my guess is that whatever point of the tube is pinched the most will be what sets the rate, so width won't matter.

Although I've been reading this thread with interest, I'm still a while from needing to add any chlorine to my pool so this project is a low priority for me. Middle of cold spell here and under my opaque solar cover, my chlorine level keeps holding. So if anyone tries this, please share your results.

Attachments

- May 31, 2011

- 248

- Pool Size

- 23000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Hi there!

Can anyone please send me their design which has been working? kinda got lost in this thread!

Thanks!

Can anyone please send me their design which has been working? kinda got lost in this thread!

Thanks!

- May 31, 2011

- 248

- Pool Size

- 23000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

- May 3, 2007

- 18,071

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

The particular design that I proposed in the first post is based on using the suction side of the pump. This allows the pump to siphon the acid or chlorine out the tank. This type of setup only works on the suction side of the pump.

Your drawing shows the return side of the pump. The only way to make that work is to have a sealed tank under pressure. This would require a tank able to handle the pressure and chemicals ($$$$). Even if you could find one, I would not recommend this because it is too dangerous. If the tank bursts, you would have chemicals exploding everywhere.

Your drawing shows the return side of the pump. The only way to make that work is to have a sealed tank under pressure. This would require a tank able to handle the pressure and chemicals ($$$$). Even if you could find one, I would not recommend this because it is too dangerous. If the tank bursts, you would have chemicals exploding everywhere.

Could you use a venturi with a bypass manifold on the return side?mas985 said:The particular design that I proposed in the first post is based on using the suction side of the pump. This allows the pump to siphon the acid or chlorine out the tank. This type of setup only works on the suction side of the pump.

- May 3, 2007

- 18,071

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

I think a venturi may be possible but it would need to have the correct design to create negative pressure at the injection port. But given the plumbing changes required for a venturi, I don't see a clear benefit in doing that over the suction side injection.

I've been working on a venturi aerator for raising my ph. I found that a length of tube at the return nozzle worked well when I held it in the right spot with my hand. When I tried to assemble a pvc piece to thread into the return and hold the tube in the right place, it got much more tricky. Once I get some photos, I'll start a new thread with instructions because I think it could be useful to others.

Point is that building the venturi by trial and error is a bit more of a challenge than I would have expected.

But here's some info I found that was useful if you're thinking of making venturi feeders for chlorine/acid.

http://leisure.prior-it.co.uk/diy-build-pond-venturi.shtml

http://leisure.prior-it.co.uk/venturi-pond-aeration.shtml

Adding the teeth to the tube certainly helped for my aerator performance.

Point is that building the venturi by trial and error is a bit more of a challenge than I would have expected.

But here's some info I found that was useful if you're thinking of making venturi feeders for chlorine/acid.

http://leisure.prior-it.co.uk/diy-build-pond-venturi.shtml

http://leisure.prior-it.co.uk/venturi-pond-aeration.shtml

Adding the teeth to the tube certainly helped for my aerator performance.

General question for passive chlorine feeder tinkerers:

How high is your pump station compared to your pool?

I would think this could make a big difference in the performance of a given setup.

For example, my pump station is in my garage, about 5 feet above the pool water level. Any time I open the strainer basket, air rushes in quickly and I loose prime unless I am really quick. I would think that almost any passive system at my pump station would still see too much suction to know to stop feeding when the pump is stopped.

Sorry if I'm recovering old ground. I read this whole thread a few weeks ago so I don't recall the contents of every post.

How high is your pump station compared to your pool?

I would think this could make a big difference in the performance of a given setup.

For example, my pump station is in my garage, about 5 feet above the pool water level. Any time I open the strainer basket, air rushes in quickly and I loose prime unless I am really quick. I would think that almost any passive system at my pump station would still see too much suction to know to stop feeding when the pump is stopped.

Sorry if I'm recovering old ground. I read this whole thread a few weeks ago so I don't recall the contents of every post.

- May 3, 2007

- 18,071

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Static head is really no different than dynamic head for this setup and the adjustment just needs to compensate for the higher suction. Having the pump 5' feet higher simply adds 5' of static head and 5.7" hg to the dynamic suction head. The more suction there is, the finer the adjustment needs to be so a Hayward needle valve might be advisable.

Thanks mas985

I also re-reviewed your Hydraulics 101 link and am now less concerned about the impact of pump station height (in comparison to the pumping suction). Very Fine adjustment valve it is.

Although now the wheels are spinning on how to use a linkage attached to the mechanical pump timer to trip a small valve open and closed... time to stop thinking about it and build something.

I also re-reviewed your Hydraulics 101 link and am now less concerned about the impact of pump station height (in comparison to the pumping suction). Very Fine adjustment valve it is.

Although now the wheels are spinning on how to use a linkage attached to the mechanical pump timer to trip a small valve open and closed... time to stop thinking about it and build something.

What a fantastic thread!!

Instead of dispensing concentrated liquid bleach, has anyone attempted/successfully created a homemade liquidator using the pool water bed? Besides "keeping out the odors," it seems to me that circulating the water instead of the liquid chlorine would help with the flow regulation, along with the other crystalization problems (ie, instead of dispensing/pumping minute amounts of liquid chlorine, you could dispense/pump larger amounts of highly chlorinated water).

I ran across the BBB method after closing my pool this year, and that's how I'm planning on opening it in the spring. If a DIY liquidator is possible, I'd like to work on it during the winter while I've got time.

Thoughts?

Instead of dispensing concentrated liquid bleach, has anyone attempted/successfully created a homemade liquidator using the pool water bed? Besides "keeping out the odors," it seems to me that circulating the water instead of the liquid chlorine would help with the flow regulation, along with the other crystalization problems (ie, instead of dispensing/pumping minute amounts of liquid chlorine, you could dispense/pump larger amounts of highly chlorinated water).

I ran across the BBB method after closing my pool this year, and that's how I'm planning on opening it in the spring. If a DIY liquidator is possible, I'd like to work on it during the winter while I've got time.

Thoughts?

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.