I just experienced a failure of a Pentair Intelliph (acid dispenser) control board, and I plan on replacing it with a home-brewed "Arduino" microcontroller-based board. Two diodes, D3 and D4 appeared fried on the native board. I don't know their function, but they may be supplying DC power to the pump motor, which will not run using "mandatory" commanding from the native board. The board led status is constant red. The pump motor runs fine when I supply it with 24 v DC, so I know it's the board that has somehow failed. The IC40 is making chlorine. The plumbing is fine, but I may replace the pump tube, just in case.

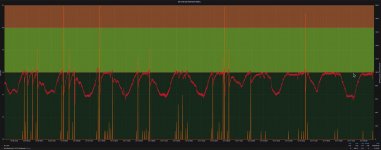

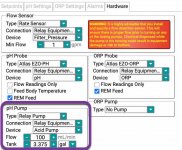

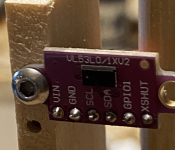

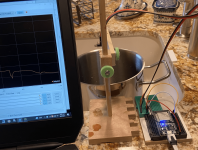

I place Arduino in quotes above, because I'm actually going to use an ESP32 microcontroller which is WiFi connected to the internet, and I will use the Arduino IDE (Integrated Development Environment) to program the microcontroller board. Basically, I'll design a unit that wakes up when power is supplied by the mother Pentair control panel, and then times the events. I'll start a recurring programmable timer to dispense a programmable amount of acid, just like the factory board. I'll shut off the IC40 chlorinator during the dispense, just like the native control board. I'll keep a record of the dispense times and amounts, and display it on a "dashboard" accessible from the internet. The amount of acid to dispense will be controlled from the internet dashboard. as well.

So, does anyone out there know of any other requirements I should include? Anyone know what the red, black, white and green wires in the connector are used for? I'll figure it out, but if someone can give me a head start, I would appreciate it. Any other Arduino enthusiasts out there that wants to contribute? Thanks...Jack Ripper.

I place Arduino in quotes above, because I'm actually going to use an ESP32 microcontroller which is WiFi connected to the internet, and I will use the Arduino IDE (Integrated Development Environment) to program the microcontroller board. Basically, I'll design a unit that wakes up when power is supplied by the mother Pentair control panel, and then times the events. I'll start a recurring programmable timer to dispense a programmable amount of acid, just like the factory board. I'll shut off the IC40 chlorinator during the dispense, just like the native control board. I'll keep a record of the dispense times and amounts, and display it on a "dashboard" accessible from the internet. The amount of acid to dispense will be controlled from the internet dashboard. as well.

So, does anyone out there know of any other requirements I should include? Anyone know what the red, black, white and green wires in the connector are used for? I'll figure it out, but if someone can give me a head start, I would appreciate it. Any other Arduino enthusiasts out there that wants to contribute? Thanks...Jack Ripper.

I like it.

I like it.