Rattus Suffocatus

Silver Supporter

- Jun 5, 2019

- 1,713

- Pool Size

- 14000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool Universal40

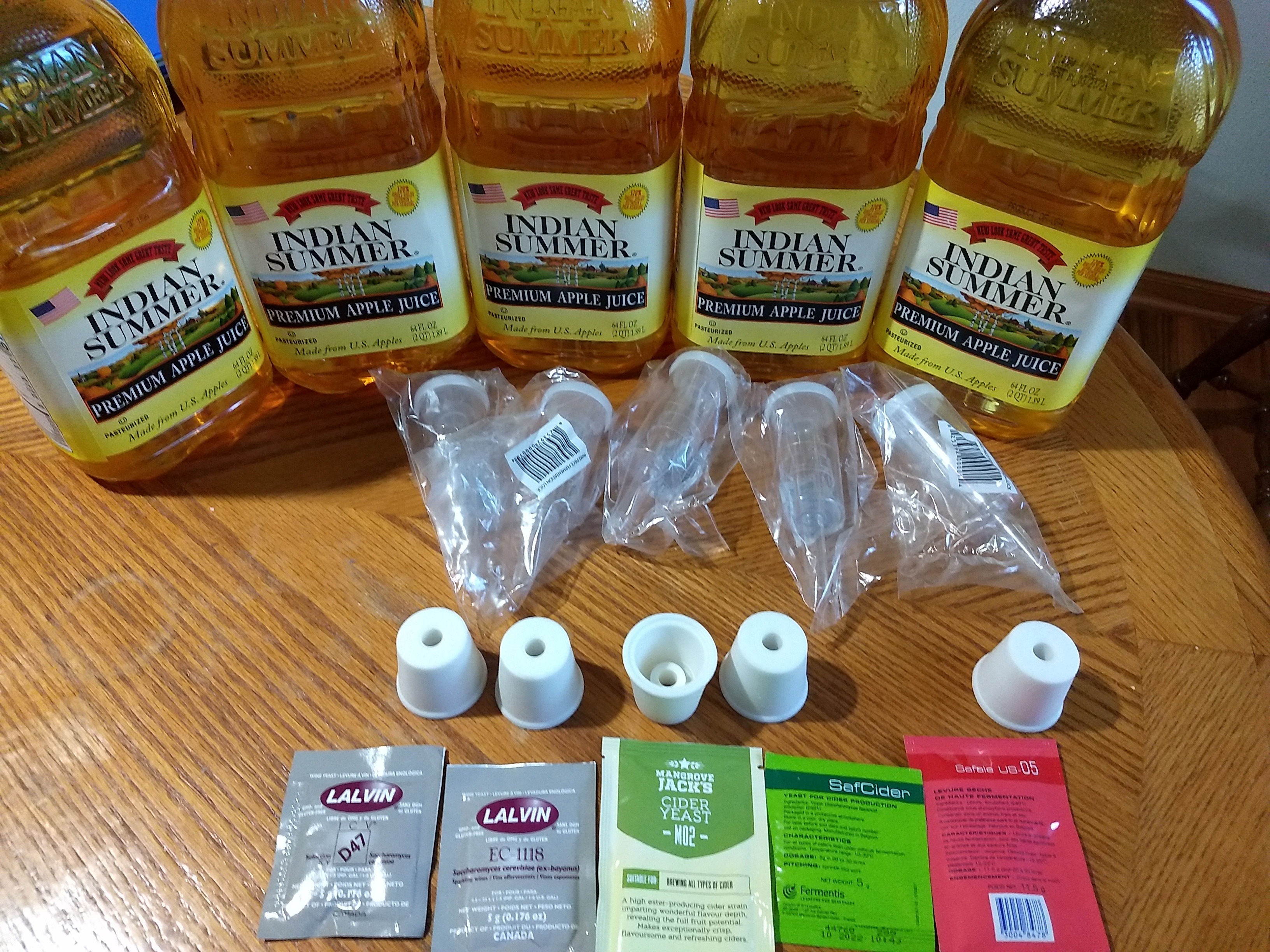

I actually picked up four gallons of apple juice myself this weekend. The local Wally only had two of the good Musselmans, so it's going to be 1/2 good have cheap. I generally do a gallon of water with enough sugar to raise the gravity a bit to dry it out... but I might pick up another gallon of the good stuff when they have it in stock again. I am awaiting the cider yeast, and I have to decide to take the keezer down for a week or two to do the 70F it needs to be to properly temperature control. So I have some time. But I am looking forward to it again... been along time.

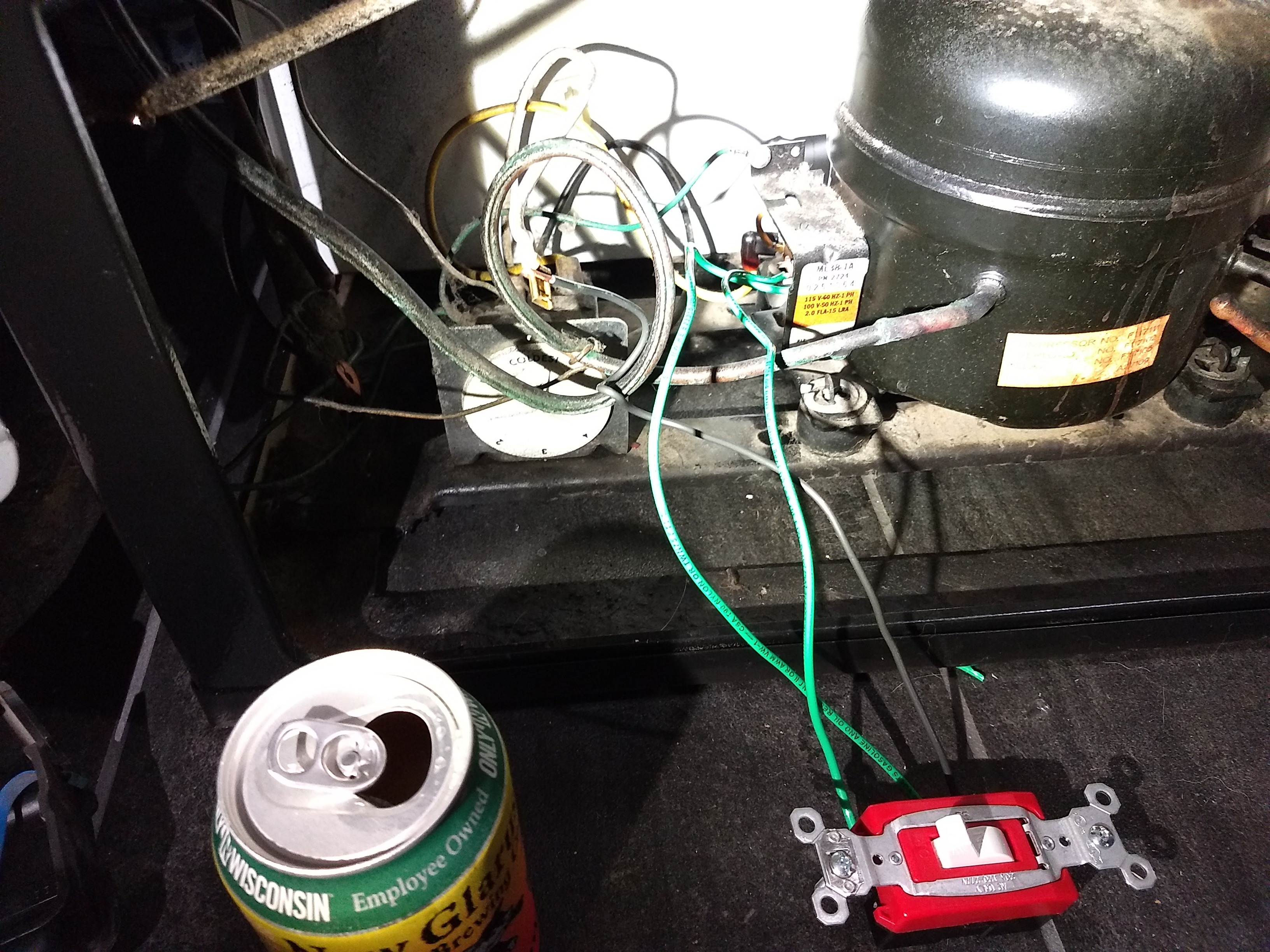

And , yah, it looks pretty sexy. Not ghetto like mine. But I wanted to be able to eventually convert back to a chest freezer if I wanted, so that is why mine is built the way it is. I figure I'll be able to tolerate doing this physically only a couple of more years to maybe five... it's heck to get old...

But yeah, that looks very nice so far.

And , yah, it looks pretty sexy. Not ghetto like mine. But I wanted to be able to eventually convert back to a chest freezer if I wanted, so that is why mine is built the way it is. I figure I'll be able to tolerate doing this physically only a couple of more years to maybe five... it's heck to get old...

But yeah, that looks very nice so far.