so wacky how the trucks were sinking. there was no rain in a week and these hoppers have to be lighter than a full tri-ax that we have been running in and out when the ground was way more wet. it sprinkled for the first 3 hours of the day.

IMG_8284

IMG_8284 by

Jim, on Flickr

IMG_8314

IMG_8314 by

Jim, on Flickr

kids had a ball. all day they played in the dirt. god love the gunite crew dealing with everyone! we had 3 generations of pool builders there. was really nice. my kids and them wanted to know when the next play date was. lol junior lived down by phili but senior lives up here so the kids come in often so we will have to get them together again.

IMG_8331

IMG_8331 by

Jim, on Flickr

IMG_8282

IMG_8282 by

Jim, on Flickr

those are my 2 young-ins with our neighbor's daughter.

ok this was the coolest part of the day! water level. i have never seen one. seniors guy who is from naples said what kinda italian and i that i never used a water level. lol the crew used this all day for getting the beam level. i guess it is more accurate than a laser level when used properly.

IMG_8271

IMG_8271 by

Jim, on Flickr

IMG_8297

IMG_8297 by

Jim, on Flickr

the word of the day was rebound. i never knew exactly what it was. i thought it was only when they start or stop the gun, but it's actually anything that hits the shell that is not immedialty covered by gunite. all gunite needs to be applied under pressure so if they spray and move and the income back to that areas after a certain amount of time it should be pulled and shovels out of the hole. junior was all over this but these guys didn't have to be told once to get it out. the only time he needed to say something was when they hit some new section and the rebar was barely covered. they shut the gun off to switch trucks. junior went over to the rebar and cleaned off all the rebar and had them do the same. he didn't want any rebar coated unless it was fully covered with a build up on it so the adherence to the rebar was again under pressure.

IMG_8327

IMG_8327 by

Jim, on Flickr

IMG_8320

IMG_8320 by

Jim, on Flickr

IMG_8309

IMG_8309 by

Jim, on Flickr

IMG_8288

IMG_8288 by

Jim, on Flickr

scrape that rebar!

IMG_0588

IMG_0588 by

Jim, on Flickr

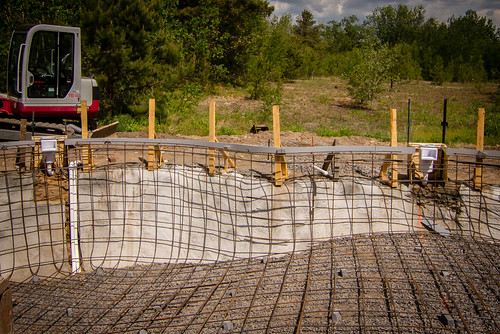

the other thing that was good the crew went over all the lines to make sure everything was level and also checked all the rebar. there was a rim around the shell they didn't like so for the first hour they and my builder added more rebar pieces and blocks and ties to make it proper.

IMG_8267

IMG_8267 by

Jim, on Flickr

IMG_8277

IMG_8277 by

Jim, on Flickr

this is one of the things the crew had to be told about. the pressure relief. they just stuck em in on top of the gravel. junior wanted them dug inputs the gravel.

IMG_8305

IMG_8305 by

Jim, on Flickr

step build out with benches

IMG_8308

IMG_8308 by

Jim, on Flickr

so after they made marks wit the water level the foreman of the crew would come and cut the top of the beam. i so wanted to play with that thing!

IMG_8302

IMG_8302 by

Jim, on Flickr

IMG_8295

IMG_8295 by

Jim, on Flickr

swim out build out:

IMG_8316

IMG_8316 by

Jim, on Flickr

IMG_8326

IMG_8326 by

Jim, on Flickr

end of the day junior went over all the penetrations to make sure they were deep enough so they get a good seal with the hydraulic cement before plaster.

IMG_8329

IMG_8329 by

Jim, on Flickr

that's it people. i know a lot of you know all this, but figured it would be nice for someone like me who didn't have a clue.

so what i took away from the day:

1. i would have been dead in the water without my pool builder there all day. they r the first line of defense to make sure no short cuts happen. i wouldn't know what to look for. we had a great crew so it was minimal, but again they knew the builder was on site also.

2. rebound. holy cow, rebound! a lot of it a lot! like so much make sure you have an extra hopper of sand! lol it can't sit on a surface unless it is applied with more ontop quickly due to it needed to be all under pressure. if the rebound sits and then gets covered that's how you get those hallow knocks on the shell which will cause issues down the road. also keep it off the rebar if more was not applied right after.

3. the water level is for true pros! lol the water level was compared to not only old school italian craftsmen, but present day latino craftsmen. oh and back in egyptian time! lol it was so awesome! i'm easy to please. lol

4. nice deep pockets for penetrations to allow for a good tight seal before plaster.

5. feed the crew. just cause it's the right thing to do cause these guys work like animals. it's so physical. so demanding. it's a long day very long. they appreciate it. and i know that cause they told me, which was nice to hear. my wife worked her butt off keeping them happy and full for when they were able to switch in and out of the hole.

6. i personally think it was really nice to only have the plumbing stubs. they were able to move them if need be without cutting anything and making a mess of a plumbing run or move the stub forward or backward on the fly to make sure they are proper, especially in areas where steps are.

that's all i got. i'm going to bed!

jim

ps i really lucked out i think so far. things might get pushed back here and there, but i think the job is going well.

- - - Updated - - -

DUDE! Your poor hands, back,shoulders, everything! Well done! I can just see the head guy laughing at you WHILE he was grabbing the shovel to help you finish THEN SIR shows up and you are DONE??? Funny stuff there!!!! You are a machine!

Sounds like you have a good plan and it is all coming together now!

Kim

(waiting on pics! LOL)

i think senior was kinda mad at first, but it was done before the day actually started. and best part. no wasted pipe! it was all moved and reheated and used. His main guy is just good. I really like him. it was nice spending the day with him. We would stop what we were each doing and talk. he is actually moving to my town. has a kid my son's age so we said we have to get them together. I like him. you should see the outdoor pizza ovens he build by hand! no kit. his own design and then he finished them however u want. crazy!