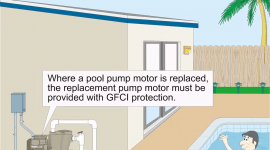

The offset is not the best, but OK, done all the time to accommodate a new pump . Biggest concern is that the installer used standard PVC fittings and threaded them in all the way, bad on both counts. If you use your spa, those fittings will eventually start to leak as the material is not designed to stay stable above 90 degrees, it shrinks, especially under the pressure of the installation (not water pressure). Not a problem with the rest of the plumbing, but is at pump fittings. Hi-temp unions should have been used, or at least a CPVC nipple or male adapter and standard pool union. The same pipe adapters are going into your filter, but are CPVC, able to handle water up to about 140 degrees. More expensive and most likely came with the filter from Hayward. Do you have, or was a GFCI breaker installed with the pump? Needed to meet code.Ok, new whisperflo VST is in. A little excitement after install as I noticed no comms cable to automation. When I questioned that I was told that the pump is not compatible with automation. But the pump will turn on/off per my automation jut like the old one. A call to store owner clarified that they have no cables in store and when they arrive I will be scheduled for cable install.

Only other thing bothering be is the offset connector into pump (was told that had to be done). Should I be concerned with this (see pic). Also told "keep speed below 3K otherwise may blow pipes".

Is the pump being turned on by a relay in your automation? The manual doesn't seem to address that (that I could find), but most VSP require constant power, regardless of what is controlling them. If it is being done that way, you will have no control over speeds when and if you use your spa without going directly to the pump and manually changing it.

Not likely to "blow your pipes" if the speed is over 3K, but, unless you need it for your spa, you wouldn't likely need anything approaching that speed.

![20221118_095413[1].jpg](/data/attachments/243/243257-3e62af55850de071faeda0ede76e90df.jpg)