- Sep 28, 2018

- 238

- Pool Size

- 13000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

TLDR: The intellicenter sensor ports are shorted together somehow, or the software/firmware inside needs to be reset.

We came out of Ian pretty fortunate here in Tampa, so I can't complain too much. However, the 12ga exterior wire I used for my solar sensor had its insulation ripped off and wire almost cut in half by a rogue tree branch - pretty surprising that there was no other apparent roof damage.

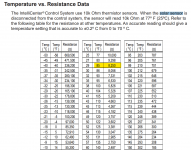

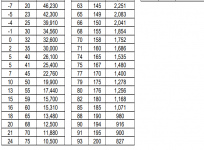

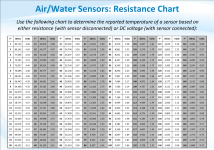

After removing the damaged part of the wire and re-splicing in the sensor, I assumed I was getting still "ERR" because the sensor was also destroyed, so I purchased a new one. However, when testing this new sensor hardwired directly into intellicenter, I get a quickly increasing temperature starting around 600 degrees, then 700, then "ERR." As before. My multimeter correctly shows around 1.2k ohms for the new sensor, and around 4.6k for the one on the roof (110 degrees).

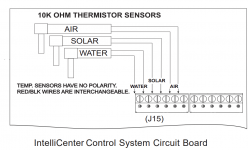

Just for a sanity check, I tested the known working water and air sensors in the solar terminals and get the same error. I tested the new sensor in the water and air sensor terminals and get the proper temperature. With nothing connected, intellicenter settles to believe the temperature is around 85 degrees, which would indicate about 1k ohms, meaning the issue is in the solar terminals themselves as if they are somehow very nearly shorted together (far too little resistance). The resistance should be essentially infinite or at least as high as the 670k resistance in the chart, representing -50 degrees. So by the time you add the sensor, the resistance goes way down and the temperature is seen as impossibly high. I've reset it several times to no avail. I haven't yet performed a factory reset, only because I'm not sure how that would help and I have SO many schedules set up.

We came out of Ian pretty fortunate here in Tampa, so I can't complain too much. However, the 12ga exterior wire I used for my solar sensor had its insulation ripped off and wire almost cut in half by a rogue tree branch - pretty surprising that there was no other apparent roof damage.

After removing the damaged part of the wire and re-splicing in the sensor, I assumed I was getting still "ERR" because the sensor was also destroyed, so I purchased a new one. However, when testing this new sensor hardwired directly into intellicenter, I get a quickly increasing temperature starting around 600 degrees, then 700, then "ERR." As before. My multimeter correctly shows around 1.2k ohms for the new sensor, and around 4.6k for the one on the roof (110 degrees).

Just for a sanity check, I tested the known working water and air sensors in the solar terminals and get the same error. I tested the new sensor in the water and air sensor terminals and get the proper temperature. With nothing connected, intellicenter settles to believe the temperature is around 85 degrees, which would indicate about 1k ohms, meaning the issue is in the solar terminals themselves as if they are somehow very nearly shorted together (far too little resistance). The resistance should be essentially infinite or at least as high as the 670k resistance in the chart, representing -50 degrees. So by the time you add the sensor, the resistance goes way down and the temperature is seen as impossibly high. I've reset it several times to no avail. I haven't yet performed a factory reset, only because I'm not sure how that would help and I have SO many schedules set up.