- Jul 21, 2013

- 65,127

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

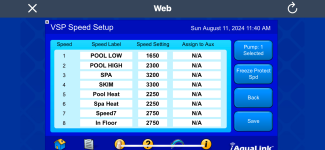

Reduce RPM 100 at a time until your SWG shows NO FLOW. Then add 300 RPM and that should be your pump low speed setting.

Add 400-500 RPM and that should be your pump high speed.

See how those speed work and then tweak them up or down.

Add 400-500 RPM and that should be your pump high speed.

See how those speed work and then tweak them up or down.