Thanks everyone for all of the help. I was at work yesterday and haven't had a chance to go through James' full troubleshooting procedure. I will try putting the system into boost mode.

Jandy AquaPure No Chlorine Production, But No Error Codes

- Thread starter socalsharky

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

If the amperage was not good, the system would show an error.

So, I think that the testing is probably off.

You need to make sure that the meter is set to DC amps or DC volts and autoranging.

For voltage, you need a solid connection to the wires and you need to watch before the system turns on and then watch for 5 minutes after the system turns on.

You can make a test rig to see if the amperage and voltage are good.

You can use a 24 volt 150 watt bulb.

If you get (2) 12 volt 75 watt bulbs, you can put them in series to make a 24 volt 150 watt test rig.

Note 75 watts actual and not "Equivalent.

Not LED bulbs, incandescent.

Disconnect the cell and connect the test rig and the lights should light up indicating that power is working.

Test amperage and it should be about 6.25 amps for 24 volts and 150 watts.

When testing amps, only clamp around one wire and not both wires.

www.westmarine.com

www.westmarine.com

aqlightinggroup.com

aqlightinggroup.com

Model # 360990 Mfg # 531075

Amperage: 6.25 Amps

Base Type: Standard

Best Use: Standard Screw Base Lamps, Sold in Pairs

Voltage: 12 Volts

Wattage: 75 Watts

Model # 360990 Mfg # 531075

3433 Via Lido Newport Beach, CA 92663-3908

lightingandsupplies.com

lightingandsupplies.com

lights.signaturelighting.com

lights.signaturelighting.com

www.1000bulbs.com

www.1000bulbs.com

SYLVANIA 54263 - FCS - T4 - 150 Watt

24 Volt - G6.35 Base - 3400 Kelvin - SYLVANIA 54263

www.bulbamerica.com

www.bulbamerica.com

www.bulbs.com

www.bulbs.com

So, I think that the testing is probably off.

You need to make sure that the meter is set to DC amps or DC volts and autoranging.

For voltage, you need a solid connection to the wires and you need to watch before the system turns on and then watch for 5 minutes after the system turns on.

You can make a test rig to see if the amperage and voltage are good.

You can use a 24 volt 150 watt bulb.

If you get (2) 12 volt 75 watt bulbs, you can put them in series to make a 24 volt 150 watt test rig.

Note 75 watts actual and not "Equivalent.

Not LED bulbs, incandescent.

Disconnect the cell and connect the test rig and the lights should light up indicating that power is working.

Test amperage and it should be about 6.25 amps for 24 volts and 150 watts.

When testing amps, only clamp around one wire and not both wires.

75 WATT A19/FROST 12V 12 VOLT INDUSTRIAL GRADE LIGHT BULB (6 PACK)

12 volt A19 light bulb 75 watts 75A19/Frost 12V frosted incandescent light bulb 75 watt 12 volts rough service e27 base marine light bulb rv bulbs

bulborama.com

12V Standard Replacement Bulbs, 75W, 6.25A, 2-Pack | West Marine

Check out our 12V Standard Replacement Bulbs, 75W, 6.25A, 2-Pack and more from West Marine!

12V 75w Frosted A19 Light Bulb

Save energy with our wide selection of low voltage light bulbs. Check out the features and functions of Low Voltage 75w Frosted A19 Bulb at AQLighting and get the best deals today!

Model # 360990 Mfg # 531075

Amperage: 6.25 Amps

Base Type: Standard

Best Use: Standard Screw Base Lamps, Sold in Pairs

Voltage: 12 Volts

Wattage: 75 Watts

Model # 360990 Mfg # 531075

3433 Via Lido Newport Beach, CA 92663-3908

Westinghouse 0473900 75 Watt T4 JC Halogen LowVage Light Bulb 3050K Clear GY6.35 Base, 12V

Shop Westinghouse 0473900 75 Watt T4 JC Halogen LowVage Light Bulb 3050K Clear GY6.35 Base, 12V online at Lightingandsupplies.com! Fast Shipping.

ItemDetail | SIGNATURE LIGHTING AND FANS

75 Watt; Halogen; T4; Clear; 2000 Average rated hours; 1350 Lumens; Bi Pin GY6.35 base; 12 Volt

Buy SYLVANIA 54263 FCS T4 150 Watt | 1000Bulbs | 1000Bulbs.com

Buy the Sylvania 54263 medical lamp. 150-watt bulb can be used in microscope and medical equipment. Great prices and fast shipping at 1000Bulbs.com!

SYLVANIA 54263 - FCS - T4 - 150 Watt

24 Volt - G6.35 Base - 3400 Kelvin - SYLVANIA 54263

FCS 64640 bulb OSRAM HLX 150w 24v G6.35 Single Ended Halogen Light Bulb

This bulb is an FCS Bulb. It uses 150 watts and 24 volts.Another Ansi Code for it is 64640. It has a G6.35 Bi-Pin base. This bulb produces 6000 lumens and has a rated life of 50 hours. APPLICATIONS: - 8mm Movie Projector - 35mm Movie Projector - 35mm Slide Projector - Bar/Night Club/Disco...

Osram 64640-HLX Projector Bulb

64640 HLX Osram halogem lamp FCS 7158 409836 JC24V-150W Bulb Type T-4 Base Type G6.

Connect the power wires to the bulb and if the bulb lights up 100%, then the unit is working.

Measure volts and amps (DC).

SYLVANIA 54263 - FCS - T4 - 150 Watt

24 Volt - G6.35 Base - 3400 Kelvin - SYLVANIA 54263

www.lightbulbs.com

www.lightbulbs.com

OSRAM 54263 150 WATT, 24 V, 4500 LUMENS, 50 Life HRS, Base: G6.35, Bulb, Clear, Filament: C-6, Halogen, T5 Shape

www.osram.us

www.osram.us

Measure volts and amps (DC).

SYLVANIA 54263 - FCS - T4 - 150 Watt

24 Volt - G6.35 Base - 3400 Kelvin - SYLVANIA 54263

#FCS 150 watt 24 volt T4 Bi-Pin Base 3400K Natural White

#FCS - 150 watt - 24 volt - T4 - Bi-Pin (G6.35) Base - 3,400K - Natural White - 64640-HLX | Sylvania Halogen Incandescent Light Bulb

OSRAM 54263 150 WATT, 24 V, 4500 LUMENS, 50 Life HRS, Base: G6.35, Bulb, Clear, Filament: C-6, Halogen, T5 Shape

FCS 64640 HLX 150W 24V 40/CS 1/SKU | OSRAM PIA

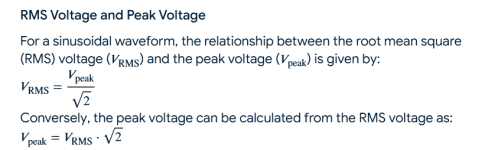

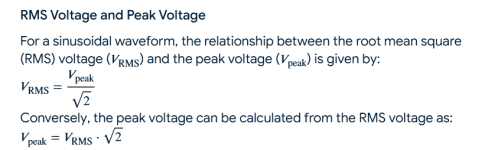

Note that AC voltage is measured as RMS value, which is the peak voltage/sqrt 2.

VRMS x sqrt 2 = VPeak

120 volts RMS = 169.7 Volts Peak to Peak.

240 volts RMS = 339.4 Volts Peak to Peak.

When voltage appears to increase coming out of a bridge rectifier, it's because a voltmeter typically reads the RMS (root mean square) value of an AC signal, while the output of a rectifier is closer to the peak voltage of the AC waveform, which is higher than the RMS value; this effect is further amplified when a filter capacitor is added, as it charges to the peak voltage and provides a relatively stable DC output close to the peak value.

So, the AC voltage out of the transformer x 1.4142 = DC voltage not under load.

Under load, the DC voltage drops by about 1 volt per amp.

So, a 30 volt DC with no load becomes about 24 volts at 6 amps of load.

Hayward has a single voltage for cell power at about 30 to 32 volts DC no load and about 24 volts under load.

Pentair and Jandy use a multitap transformer to adjust the voltage to the cell to try to make the cell current relatively constant for different salinity and different water temperatures.

This can make measuring the Pentair and Jandy voltages more difficult.

The Jandy circuit board has voltage test points that you can use if you have the technical manual showing the correct test spots.

VRMS x sqrt 2 = VPeak

120 volts RMS = 169.7 Volts Peak to Peak.

240 volts RMS = 339.4 Volts Peak to Peak.

When voltage appears to increase coming out of a bridge rectifier, it's because a voltmeter typically reads the RMS (root mean square) value of an AC signal, while the output of a rectifier is closer to the peak voltage of the AC waveform, which is higher than the RMS value; this effect is further amplified when a filter capacitor is added, as it charges to the peak voltage and provides a relatively stable DC output close to the peak value.

So, the AC voltage out of the transformer x 1.4142 = DC voltage not under load.

Under load, the DC voltage drops by about 1 volt per amp.

So, a 30 volt DC with no load becomes about 24 volts at 6 amps of load.

Hayward has a single voltage for cell power at about 30 to 32 volts DC no load and about 24 volts under load.

Pentair and Jandy use a multitap transformer to adjust the voltage to the cell to try to make the cell current relatively constant for different salinity and different water temperatures.

This can make measuring the Pentair and Jandy voltages more difficult.

The Jandy circuit board has voltage test points that you can use if you have the technical manual showing the correct test spots.

The 24 volt light should work.Blue to Blue/white is 37.5 Volts AC at 6 amps and this is the power for the cell.

You can also use (3) 12 volt, 75 watt lights in series to make a 36 volt, 225 watt, 6.25 amp tester.

You can use (1) 12 volt, 75 watt, 6.25 amp light in series with a 24 volt, 150 watt, 6.25 amp bulb to make a 36 volt, 225 watt, 6.25 amp tester.

For loads in series, the amperage does not add up, but the wattage and voltage does add up.

The voltage divides based on the load.

For example, a total 36 volt, 225 watt, 6.25 amp load will give (36 x 75/225) 12 volts to the 12 volt light and (36 x 150/225) 24 volts to the 24 volt light.

Last edited:

I thought I would give the system some time to see if the problems cleared up on their own, but that didn't happen. The cell is still not producing chlorine. Now it is throwing error codes 125 and 194. It looks like the cell, or perhaps the whole chlorinator system is toast.

Based on consulting with a few professionals and a bunch of online research (including TFP) I am strongly considering switching to the Pentair Intellichlor 40.

Based on consulting with a few professionals and a bunch of online research (including TFP) I am strongly considering switching to the Pentair Intellichlor 40.

- Jul 21, 2013

- 65,062

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

If you are going to keep your Aqualink then stay with the Aquapure.

The IntelliChlor cannot be controlled by the Aqualink and will only do 20% adjustment increments.

The IntelliChlor cannot be controlled by the Aqualink and will only do 20% adjustment increments.

I like the idea of being able to control the SWG thru my Aqualink, but it seems like the Jandy AquaPure SWG's are junk. It's a regular 2-year replacement cycle at $1000 each. My Hayward system at the last house lasted twice that long, and I hear that Pentair is even better.If you are going to keep your Aqualink then stay with the Aquapure.

The IntelliChlor cannot be controlled by the Aqualink and will only do 20% adjustment increments.

Last edited:

- Jul 21, 2013

- 65,062

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Yes, but Pentair IntelliChlor without Pentair automation can only be adjusted in 20% increments.I hear that Pentair is even better.

If you are set on dumping your Aquapure look at the Circupool RJ+....

Circupool SWG - Further Reading

You can control a Hayward AquaRite SWG through the Aqualink if you use a converter board. Read Jandy Aqualink RS - Further Reading

BTW, I dumped all my Jandy equipment and Aqualink and installed a Pentair IntelliCenter. I am happy I did.

Replacing an Aqualink with an IntelliCenter

This thread is for me to work out what I do in upgrading my 20 year old pool equipment. Jandy RS8 automation, 1.5HP SS Pentair pump, Pentair Mastertemp 400 NG heater, IC40 SWG, typical pool/spa combo with spa spillover, Pentair JVA actuators on suctions & return Jandy valves, 1HP pump for spa...

What about Jandy Tru Clear? I just came across that one, and it seems to be more reliable than the AquaPure.

- Jul 21, 2013

- 65,062

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

TruClear is junk. Worse than the Aquapure.What about Jandy Tru Clear? I just came across that one, and it seems to be more reliable than the AquaPure.

I don't know where you're reading your stuff.

The internet of course.TruClear is junk. Worse than the Aquapure.

I don't know where you're reading your stuff.

OK, good to know. What is the approximate cost of replacing my panel with an IntelliCenter? Would it work with Jandy VF pumps and Jandy heater?

Another option is to go with a CircuPool SWCG. Call them and ask about the new series that is coming out with remote control. It may mean having to work off of 2 apps but far cheaper then buying a IntelliCenter with a IC SWCG. Something to consider.The internet of course.

OK, good to know. What is the approximate cost of replacing my panel with an IntelliCenter? Would it work with Jandy VF pumps and Jandy heater?

- Jul 21, 2013

- 65,062

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

What is the approximate cost of replacing my panel with an IntelliCenter?

Pentair Automation Systems - Further Reading

Would it work with Jandy VF pumps

No. I had got a Pentair IntellifloPump I was using with my Aqualink.

Yes.and Jandy heater?

Sam721

Active member

If "LO" is shown on the display, you can still get the cell to turn on by setting it to "Boost" the pool. This overrides the low temperature stopping production.

If "LO" is NOT shown, it should turn on the cell. You can verify with the "Cell on" light which will always light up when the cell is being powered. Any problems with the cell do not result in error messages immediately and some reset themselves pretty quickly so they are easy to miss. Measure the voltage and amps on the DC connection to the cell, that will tell you if it's working good or not. The amps need to be 4.5 - 6.8A to work nominally. As the control board will try to maintain this current it will vary the voltage between 22-28VDC nominally. My system has been pushing close to 34VDC to maintain the current and I'm wondering if that's shortening the life of my cells (average 1.5 seasons which is ridiculous).

See my post for pics and the cell repair I've been doing.

If "LO" is NOT shown, it should turn on the cell. You can verify with the "Cell on" light which will always light up when the cell is being powered. Any problems with the cell do not result in error messages immediately and some reset themselves pretty quickly so they are easy to miss. Measure the voltage and amps on the DC connection to the cell, that will tell you if it's working good or not. The amps need to be 4.5 - 6.8A to work nominally. As the control board will try to maintain this current it will vary the voltage between 22-28VDC nominally. My system has been pushing close to 34VDC to maintain the current and I'm wondering if that's shortening the life of my cells (average 1.5 seasons which is ridiculous).

See my post for pics and the cell repair I've been doing.

Mine never displayed LO. Water temp does not seem to be the issue. Boost did not help. Based on the current error codes I think my cell is dead.If "LO" is shown on the display, you can still get the cell to turn on by setting it to "Boost" the pool. This overrides the low temperature stopping production.

If "LO" is NOT shown, it should turn on the cell. You can verify with the "Cell on" light which will always light up when the cell is being powered.

I would do the load test with the light to determine if the problem is with the cell or the power supply.

Sam721

Active member

If the "cell on" light is on, you should see voltage above 19V at the DC leads to the cell, if not, your PCB is dead. If you do see voltage but 0 amps, the cell is broken. You may be able to repair with some ingenuity, see my link in previous post.I would do the load test with the light to determine if the problem is with the cell or the power supply.