IntelliCenter Quick Reference/Information Guide

- Thread starter MyAZPool

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Oct 25, 2015

- 5,812

- Pool Size

- 28000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

Every additional new information is very helpful to the DIY community. Thanks to Ron for the posts and Allen for making this readily available in Wiki.

Ron any update on the next version of the apps? This is the time of year where I'd like to make changes to my swg schedule with the app. I never have lost ability to do this at the power center but it would be nice if they can get another cycle on the apps.

Chris

Ron any update on the next version of the apps? This is the time of year where I'd like to make changes to my swg schedule with the app. I never have lost ability to do this at the power center but it would be nice if they can get another cycle on the apps.

Chris

Matterpro,This post is amazing and was exactly what I needed. So, first off, thank you for all this hard work and research.

Thanks.. I'm really glad you were able to glean some useful information from the thread.

Regarding your UltraTemp, yep, I did see where tech support got you squared away on that. I had known about that previously, but never thought to address it in my IntelliCenter threads. Glad you brought it up now and I see where @ajw22 has taken the time to add it to the UltraTemp Wiki, so looks like that base is covered.I installed over the weekend and turned it on Monday. I've figured out how to get it all running, and am working on schedules and groups. My only hiccup is despite all my efforts, the Intellicenter is failing to control the UltraTemp heat pump. It sees it, and the heartbeat shows it's connected on the pump side, but it won't kick on. The heat pump works manually just fine, just not through the RS-485 connection from the controller. Looks like this is not new, and EasyTouch and IntelliTouch had the same issues. I've changed the address to 2 on the intellicenter and the heater, in case there is conflict with the Pump on address 1. Still no love. Wondering if I should just use Relay mode instead. Thoughts?

I'll address your IntelliChlor and what Pentair Tech support said about it momentarily, as I have some material that you may find useful. Standby on that.The Intellichlor (linked through the Intelliph) also keeps sending alerts that it's lost connection, then immediately says it's back.

r.

- Jul 21, 2013

- 65,158

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Great! And will do!

I came across this mention of the Solar Sensor on page 13 point 9 of the UltraTemp manual...

Solar temperature sensor could be left loose in load center. The automation system does not use the temperature reading but just looks for resistance.

matterproOn another note, I asked why I couldn't schedule run times for the Intellichlor; it runs non-stop whenever the pool is "on". Since I want to run the heat pump, for extended times to get the temp up, but not chlorinate the whole time he said that the only way he knows how to do it is to run the IntelliPH/IntelliChlor through an Aux relay. Not sure if that's the case, but I'll keep playing around with it.

In the meantime @MyAZPool It might be a good idea to mention the need for all three temp sensors to make UltraTemp heat pumps work with the automation through RS-485 communication.

So it appears that you have stumbled on to something that has only been brought up a couple of times because its fairly "non-standard".

I too have a need to "schedule" my IntelliChlor for a couple of different reasons and I will explain below. This is not something that most do but its what I and just a couple of others choose to do, hence the term "non-standard".

Tech Support is correct. The way to do that is to wire the SWCG transformer through an AUX relay. Not only do I do that with my IntelliChlor but also my heater as well (something that you should not do with an UltraTemp and really have no need to).

Here are the details.

“Jumpering” Relays: Some users of the IntelliCenter (and other automation systems as well), use a non-standard method that I will refer to as a “jumpered” relay. It should be noted that the IntelliCenter must have enough extra or spare relays in order to employ this non-standard method.

Caution: Care and understanding of this principle must be used with this or any other type of non-standard installation as wiring relays together incorrectly, can cause serious damage to equipment and should only be attempted when a user is experienced with this type of installation and thoroughly understands what they are doing.

This method was first employed by users of the Pentair EasyTouch and IntelliTouch automation systems which is where I first noticed this type of non-standard installation method. This installation method allows for the line-side of a secondary (AUX) relay to be energized ONLY when the following two conditions exist.

This method was first employed by users of the Pentair EasyTouch and IntelliTouch automation systems which is where I first noticed this type of non-standard installation method. This installation method allows for the line-side of a secondary (AUX) relay to be energized ONLY when the following two conditions exist.1. The primary relay (i.e. the Filter Pump Relay) is activated through the control system, thus energizing the load-side of the primary relay and,

2. The secondary or “jumpered” relay (AUX) circuit is also activated through the control system, thus energizing the load-side of the secondary relay.

This method of “jumpering” relays is not a requirement in most cases and is only used when a user desires added control over the On/Off function of various pool equipment or accessories, when that pool equipment requires that the pool pump circuit is first energized.

Some users (including myself) use this method for example in order to maintain additional control over when power is delivered to their IntelliChlor unit (On), through the use of a separate relay specifically devoted to the IntelliChlor and/or IntellipH.

However, this IntelliChlor (and IntellipH if installed) AUX relay can NOT be energized by only activating its circuit. The Filter Pump circuit must be first activated which will then deliver power to the line-side of the AUX relay and then allow the load-side of the AUX relay to be energized.

NOTE: When utilizing a Pentair IntelliFlo Pump as the filter pump, it is important to note that if the IntelliFlo pump power is wired correctly, then the activation of the Filter Pump Relay is NOT what delivers power to the pump.

The IntelliFlo pump should be wired HOT at all times either by wiring it to the LINE side of the filter pump relay or directly to the breaker (either method will deliver the same result).

By activating the Filter Pump circuit, it activates the pump motor via the properly connected pump control cable. But by doing so, it also energizes the LOAD side of the Filter Pump Relay.

This then essentially delivers power to the LINE side of the IntelliChlor relay when this non-standard installation method is utilized and thus, just ensures that the pump motor is running before the LOAD side of the IntelliChlor relay can be energized through its associated circuit.

This method allows a user to completely control when power is delivered to the IntelliChlor and/or IntellipH (through this separate circuit), so long as the filter pump relay is first energized.

This method is useful as an example during the winter months in many locales when the pool water temperature falls below approximately 60-55 degrees F., and the IntelliChlor cell does not actually operate anyway because the temperature sensor inhibits the activation of the salt cell.

When this occurs, the IntelliChlor cell will not operate and so in my mind, there is really no good reason to power the IntelliChlor transformer, the IntelliChlor circuit board and consequently the IntelliChlor unit electronics.

The procedure to implement this non-standard installation method requires that the user connect “jumper” leads from the LOAD side of the Filter Pump relay to the LINE side of another AUX relay and then connect the IntelliChlor transformer to the LINE side of this second relay as illustrated below.

Then the user can create individual Circuit Groups established for both winter months (which does not include the IntelliChlor circuit) and for summer months (does include the IntelliChlor circuit). The user can then schedule those Circuit Groups as applicable.

In summary, the summer Circuit Group(s) activate the IntelliChlor circuit and the winter Circuit Group(s) do not activate the IntelliChlor circuit.

In addition, it should be noted that if an IntellipH is installed and the user wishes to manually dose in the winter, the user only needs to activate the circuit that controls the IntelliChlor transformer. Wait about a minute and the IntellipH is now available for manual dosing. When complete with the manual dosing, just deactivate the circuit that controls the IntelliChlor transformer and everything is back to normal.

When I conduct my manual testing in the winter and I find pH may have inched up and I need a couple of squirts of acid, I pull my phone out, open the IntelliCenter app, activate the pool circuit (if its off) and the IntelliChlor circuit (in my case named "sanitation") and then start making my way to the pad. Once there, I can almost begin a quick manual dose of acid and I'm good.

r.

Last edited:

That's exactly where I initially saw that.I came across this mention of the Solar Sensor on page 13 point 9 of the UltraTemp manual...

Solar temperature sensor could be left loose in load center. The automation system does not use the temperature reading but just looks for resistance.

Chris,Every additional new information is very helpful to the DIY community. Thanks to Ron for the posts and Allen for making this readily available in Wiki.

Ron any update on the next version of the apps? This is the time of year where I'd like to make changes to my swg schedule with the app. I never have lost ability to do this at the power center but it would be nice if they can get another cycle on the apps.

Chris

Good question. I received a bit of "not very encouraging" information on Tuesday. Since the COVID-19 work shutdown, little to no progress on the several IntelliCenter software issues has been made by the Pentair Software Development and Engineering teams. I kind of anticipated as much and I'm just in "hold" mode in order to try and get some movement on the issues that we are both aware of.

All I got for now.

r.

matterpro

New member

I came across this mention of the Solar Sensor on page 13 point 9 of the UltraTemp manual...

Solar temperature sensor could be left loose in load center. The automation system does not use the temperature reading but just looks for resistance.

Great catch! I misread "left loose" as meaning "not needed" and glossed over the resistance part. I'm digging through my box of electronics parts to see if I have a 10K ohm resistor I can insert instead of a temp sensor. In theory it should provide the required resistance and be a cleaner solution than another entire cable and sensor. I'll report back if it's a go.

“Jumpering” Relays: Some users of the IntelliCenter (and other automation systems as well), use a non-standard method that I will refer to as a “jumpered” relay.

Perfect. I was actually considering this very method to ensure the pump was running, good to hear that it's what you do already. Starting to think I should have gotten the box with more relays installed! Using an Aux for the intellichlor will be my last open relay, but I can always add more if needed down the road. Thanks again for another excellent description and write up.

- Jul 21, 2013

- 65,158

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Great catch! I misread "left loose" as meaning "not needed" and glossed over the resistance part. I'm digging through my box of electronics parts to see if I have a 10K ohm resistor I can insert instead of a temp sensor. In theory it should provide the required resistance and be a cleaner solution than another entire cable and sensor. I'll report back if it's a go.

10K resistor is all you need. You would think they would include a 25 cent item in the Heat Pump stuff or IntelliCenter stuff instead of telling you that you need to buy a $25-$80 temperature sensor. I really think that Pentair people don't think this stuff through.

but I can always add more if needed down the road.

That is the nice thing about the IntelliCenter that it is modular expandable.

All,

Those posts that were here in this thread regarding alternative methods of interfacing with IntelliCenter, were moved to the following more applicable thread.

www.troublefreepool.com

We kind of got "off-topic" (mostly my fault) and went down a different rabbit hole. The thread above will be a better repository for that information.

www.troublefreepool.com

We kind of got "off-topic" (mostly my fault) and went down a different rabbit hole. The thread above will be a better repository for that information.

Sorry for the inconvenience.

Stay safe.

r.

Those posts that were here in this thread regarding alternative methods of interfacing with IntelliCenter, were moved to the following more applicable thread.

IntelliCenter Home Automation Integration and Control

Ah! I think there is a misunderstanding... You need to replace 'xx' with the number of the aux circuit connected to the light, not with the number of on/off cycles. So if your light is connected to Aux Circuit 3 then the commands for one off/on cycle would be...

Sorry for the inconvenience.

Stay safe.

r.

Last edited:

SA Pentair User

Well-known member

Control4 integration with IntelliCenter is OK. Integration with ScreenLogic is poor.

Control4 (as a home automation system) is way better than Crestron (my view) and cheaper.

In terms of IntelliCenter integration, it is useful for linking Pentair circuits to other equipment (for instance, at my holiday house, I turn my pool heaters off when the Sauna and Steam Room are both turned on - this is to prevent me overloading the electricity board). I have also linked the pool lights to some of my Control4 lighting scenes so that one button (On a light switch) turns on all my outside lights (Control4) and the Pool Lights (IntelliCenter).

Pool (pumps and heat), spa (pumps and heat) and light control is good (although no colour control).

Circuit control via Control4 is poor (although this should be fixed soon - and yes, they have been saying that for 6 months) as only group circuits can be controlled (not regular circuits or feature circuits)... should be easy to fix... but so far, NOT.

Setup is easy. As long as Control4 and the Intellicenter are on the same network, simply type in the IP address of the Intellicenter into the Control4 driver and it is all done for you.

I always use the Pentair App for Intellicenter control but have linked (automated) a number of things so that they link up with other automation via control 4 (examples above). Another example is a ”Romance” button which dims all the lights, turns on the jacuzzi jets and starts playing Air Supply and Abba (my wife’s choice - don’t judge me!).

Control4 (as a home automation system) is way better than Crestron (my view) and cheaper.

In terms of IntelliCenter integration, it is useful for linking Pentair circuits to other equipment (for instance, at my holiday house, I turn my pool heaters off when the Sauna and Steam Room are both turned on - this is to prevent me overloading the electricity board). I have also linked the pool lights to some of my Control4 lighting scenes so that one button (On a light switch) turns on all my outside lights (Control4) and the Pool Lights (IntelliCenter).

Pool (pumps and heat), spa (pumps and heat) and light control is good (although no colour control).

Circuit control via Control4 is poor (although this should be fixed soon - and yes, they have been saying that for 6 months) as only group circuits can be controlled (not regular circuits or feature circuits)... should be easy to fix... but so far, NOT.

Setup is easy. As long as Control4 and the Intellicenter are on the same network, simply type in the IP address of the Intellicenter into the Control4 driver and it is all done for you.

I always use the Pentair App for Intellicenter control but have linked (automated) a number of things so that they link up with other automation via control 4 (examples above). Another example is a ”Romance” button which dims all the lights, turns on the jacuzzi jets and starts playing Air Supply and Abba (my wife’s choice - don’t judge me!).

So, only one wire connection is required ?I came across this mention of the Solar Sensor on page 13 point 9 of the UltraTemp manual...

Solar temperature sensor could be left loose in load center. The automation system does not use the temperature reading but just looks for resistance.

@JamesW does this impact our connection with FPH?

The sensor uses 2 wire connections.

The reference is for heat pumps set up as solar where the air temperature is used to determine if it's worthwhile to run the heat pump.

It does not affect your plans.

Note that the quote from the manual is misleading.

There are two ways to set up a heat pump.

One way is to set it up to run whenever the water temperature is lower than the set point. In this case, no solar sensor is used.

The other way is to set it up as solar.

When set as solar, you connect a temperature sensor to the solar temperature sensor terminal and mount the sensor the same way that you mount the air temperature sensor.

Heat pumps work best in warm/hot conditions. So, setting up a heat pump as solar ensures that the heat pump only runs during good conditions such as day and not night.

Using a resistor in the solar temperature sensor terminal defeats the purpose of setting the heat pump as solar.

If you want the heat pump to run on demand without regard to air temperature, just set it up as a normal heater.

There are two ways to set up a heat pump.

One way is to set it up to run whenever the water temperature is lower than the set point. In this case, no solar sensor is used.

The other way is to set it up as solar.

When set as solar, you connect a temperature sensor to the solar temperature sensor terminal and mount the sensor the same way that you mount the air temperature sensor.

Heat pumps work best in warm/hot conditions. So, setting up a heat pump as solar ensures that the heat pump only runs during good conditions such as day and not night.

Using a resistor in the solar temperature sensor terminal defeats the purpose of setting the heat pump as solar.

If you want the heat pump to run on demand without regard to air temperature, just set it up as a normal heater.

matterpro

So it appears that you have stumbled on to something that has only been brought up a couple of times because its fairly "non-standard".

I too have a need to "schedule" my IntelliChlor for a couple of different reasons and I will explain below. This is not something that most do but its what I and just a couple of others choose to do, hence the term "non-standard".

Tech Support is correct. The way to do that is to wire the SWCG transformer through an AUX relay. Not only do I do that with my IntelliChlor but also my heater as well (something that you should not do with an UltraTemp and really have no need to).

Here are the details.

“Jumpering” Relays: Some users of the IntelliCenter (and other automation systems as well), use a non-standard method that I will refer to as a “jumpered” relay. It should be noted that the IntelliCenter must have enough extra or spare relays in order to employ this non-standard method.

Caution: Care and understanding of this principle must be used with this or any other type of non-standard installation as wiring relays together incorrectly, can cause serious damage to equipment and should only be attempted when a user is experienced with this type of installation and thoroughly understands what they are doing.

View attachment 134336This method was first employed by users of the Pentair EasyTouch and IntelliTouch automation systems which is where I first noticed this type of non-standard installation method. This installation method allows for the line-side of a secondary (AUX) relay to be energized ONLY when the following two conditions exist.

1. The primary relay (i.e. the Filter Pump Relay) is activated through the control system, thus energizing the load-side of the primary relay and,

2. The secondary or “jumpered” relay (AUX) circuit is also activated through the control system, thus energizing the load-side of the secondary relay.

This method of “jumpering” relays is not a requirement in most cases and is only used when a user desires added control over the On/Off function of various pool equipment or accessories, when that pool equipment requires that the pool pump circuit is first energized.

Some users (including myself) use this method for example in order to maintain additional control over when power is delivered to their IntelliChlor unit (On), through the use of a separate relay specifically devoted to the IntelliChlor and/or IntellipH.

However, this IntelliChlor (and IntellipH if installed) AUX relay can NOT be energized by only activating its circuit. The Filter Pump circuit must be first activated which will then deliver power to the line-side of the AUX relay and then allow the load-side of the AUX relay to be energized.

NOTE: When utilizing a Pentair IntelliFlo Pump as the filter pump, it is important to note that if the IntelliFlo pump power is wired correctly, then the activation of the Filter Pump Relay is NOT what delivers power to the pump.

The IntelliFlo pump should be wired HOT at all times either by wiring it to the LINE side of the filter pump relay or directly to the breaker (either method will deliver the same result).

By activating the Filter Pump circuit, it activates the pump motor via the properly connected pump control cable. But by doing so, it also energizes the LOAD side of the Filter Pump Relay.

This then essentially delivers power to the LINE side of the IntelliChlor relay when this non-standard installation method is utilized and thus, just ensures that the pump motor is running before the LOAD side of the IntelliChlor relay can be energized through its associated circuit.

This method allows a user to completely control when power is delivered to the IntelliChlor and/or IntellipH (through this separate circuit), so long as the filter pump relay is first energized.

This method is useful as an example during the winter months in many locales when the pool water temperature falls below approximately 60-55 degrees F., and the IntelliChlor cell does not actually operate anyway because the temperature sensor inhibits the activation of the salt cell.

When this occurs, the IntelliChlor cell will not operate and so in my mind, there is really no good reason to power the IntelliChlor transformer, the IntelliChlor circuit board and consequently the IntelliChlor unit electronics.

The procedure to implement this non-standard installation method requires that the user connect “jumper” leads from the LOAD side of the Filter Pump relay to the LINE side of another AUX relay and then connect the IntelliChlor transformer to the LINE side of this second relay as illustrated below.

View attachment 134340

Then the user can create individual Circuit Groups established for both winter months (which does not include the IntelliChlor circuit) and for summer months (does include the IntelliChlor circuit). The user can then schedule those Circuit Groups as applicable.

View attachment 134344

View attachment 134346

In summary, the summer Circuit Group(s) activate the IntelliChlor circuit and the winter Circuit Group(s) do not activate the IntelliChlor circuit.

In addition, it should be noted that if an IntellipH is installed and the user wishes to manually dose in the winter, the user only needs to activate the circuit that controls the IntelliChlor transformer. Wait about a minute and the IntellipH is now available for manual dosing. When complete with the manual dosing, just deactivate the circuit that controls the IntelliChlor transformer and everything is back to normal.

When I conduct my manual testing in the winter and I find pH may have inched up and I need a couple of squirts of acid, I pull my phone out, open the IntelliCenter app, activate the pool circuit (if its off) and the IntelliChlor circuit (in my case named "sanitation") and then start making my way to the pad. Once there, I can almost begin a quick manual dose of acid and I'm good.

r.

I'm almost complete on a new pool build with an Intellicenter 521906 controlling everything (1 intelliflo pump, IC60, 2 Intellivalves, MasterTemp 400, water feature pump, lights...etc) Question about jumping relays to be able to control the IC60 independently...In your above example, you have 1 circuit breaker feeding your pump, IntelliChlor, and Heater all through the pump relay or am I missing something? Can the pump and the heater be on the same GFCI circuit breaker without causing any issues?

I believe my electrician has mine currently wired incorrectly (my intelliflo is wired through the load side of the pump relay) and I would like to do it the way you've described, I just want to make sure I understand correctly while I explain it to the electrician.

WerdnaycartI'm almost complete on a new pool build with an Intellicenter 521906 controlling everything (1 intelliflo pump, IC60, 2 Intellivalves, MasterTemp 400, water feature pump, lights...etc) Question about jumping relays to be able to control the IC60 independently...In your above example, you have 1 circuit breaker feeding your pump, IntelliChlor, and Heater all through the pump relay or am I missing something? Can the pump and the heater be on the same GFCI circuit breaker without causing any issues?

You are correct. I am powering my VSF, the IntelliChlor transformer and the electrical functions of my gas heater off of the same 20 Amp breaker. But keep in mind the IC xformer only draws 0.1A and the electronics of my gas heater only draws .5 amps. I looked for the amperage draw of the MasterTemp Gas heater but couldn't find it in the Installation and Users Guide, so you might want to confirm it. I wouldn't think that it's over an amp for the electronics of that heater.

Some recommend placing the filter pump on it's own dedicated breaker and if you have extra breakers, no problem. I did not have that luxury without adding an additional auxiliary load center, so I chose this method. In nearly two years using this configuration, no problem with the pump or the breaker. I even did a test, where I had all three energized and kicked the pump up to its maximum of 3450 RPM and let it run for about 5 minutes in the Phoenix, AZ summer heat. No problem.

Here is how I have elected to configure my load center breaker configuration. Other's may choose different options, but this works out really well for me.

r.

Last edited:

- Jan 2, 2018

- 563

- Pool Size

- 24500

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

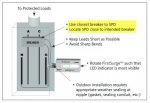

That might very well be true if one were to choose to mount the SPD upside down on the top of the Load Center (which I would highly NOT recommend since the top of the load center is adjacent to the low-voltage compartment or to the side (which again is NOT advisable on the left side of the Load Center).I thought the surge protection breaker was supposed to be the first breaker?

But in my case, I choose to mount my SPD in the most logical location in my opinion (which was at the bottom of the Load Center), so the "closest" breaker is located in breaker slots 9/10.

r.

Last edited:

Werdnaycart

You are correct. I am powering my VSF, the IntelliChlor transformer and the electrical functions of my gas heater off of the same 20 Amp breaker. But keep in mind the IC xformer only draws 0.1A and the electronics of my gas heater only draws .5 amps. I looked for the amperage draw of the MasterTemp Gas heater but couldn't find it in the Installation and Users Guide, so you might want to confirm it. I wouldn't think that it's over an amp for the electronics of that heater.

Some recommend placing the filter pump on it's own dedicated breaker and if you have extra breakers, no problem. I did not have that luxury without adding an additional auxiliary load center, so I chose this method. In nearly two years using this configuration, no problem with the pump or the breaker. I even did a test, where I had all three energized and kicked the pump up to its maximum of 3450 RPM and let it run for about 5 minutes in the Phoenix, AZ summer heat. No problem.

Here is how I have elected to configure my load center breaker configuration. Other's may choose different options, but this works out really well for me.

r.

View attachment 145186

Wow, this is great. You have no idea how much time you've saved me. There's not a lot of information out there on the intellicenter (at least that I've been able to find). This thread has been an amazing resource. Thank you so much for the information. I was coming up short for my SPD, but if I wire like you have I should have plenty of space.

Cool.. Just try to confirm the total amperage draw of the MasterTemp 400. I don't want to take a guess and then be wrong on that and I can't seem to find a reference anywhere. It can't be much though. The fuse for the fireman's switch is only 1.5 amps for gosh sakes. Like I said, mine is only 0.5 amps but it doesn't have all of the electronics that the MasterTemp has.Wow, this is great. You have no idea how much time you've saved me. There's not a lot of information out there on the intellicenter (at least that I've been able to find). This thread has been an amazing resource. Thank you so much for the information. I was coming up short for my SPD, but if I wire like you have I should have plenty of space.

Let's ask @bdavis466 . He is the one who initially gave me the idea of jumpering the heater relay off of the load side of the pump relay and besides, he is a lot smarter than I am (notice, I didn't say more good looking though

r.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.