- Jul 21, 2013

- 65,062

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

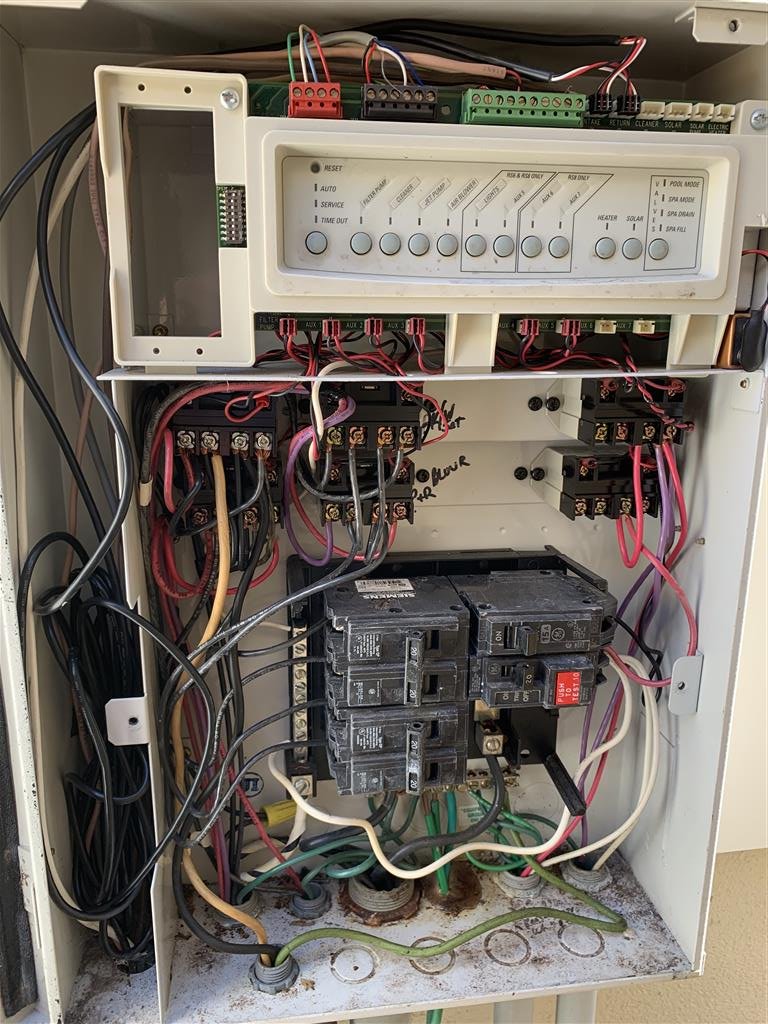

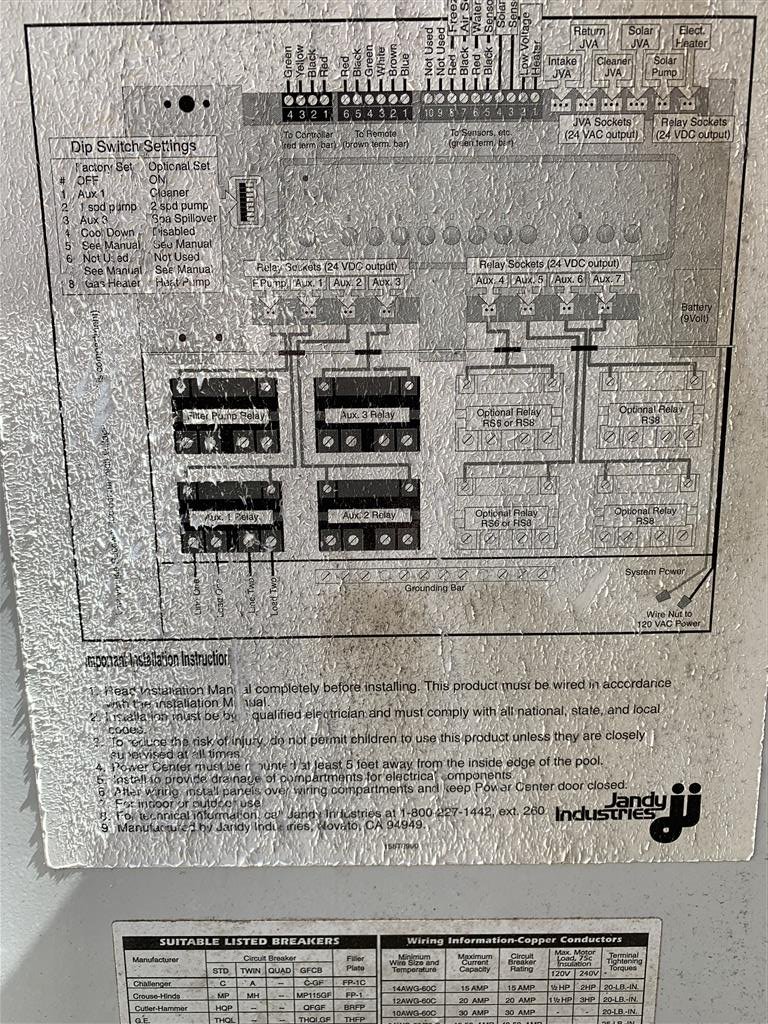

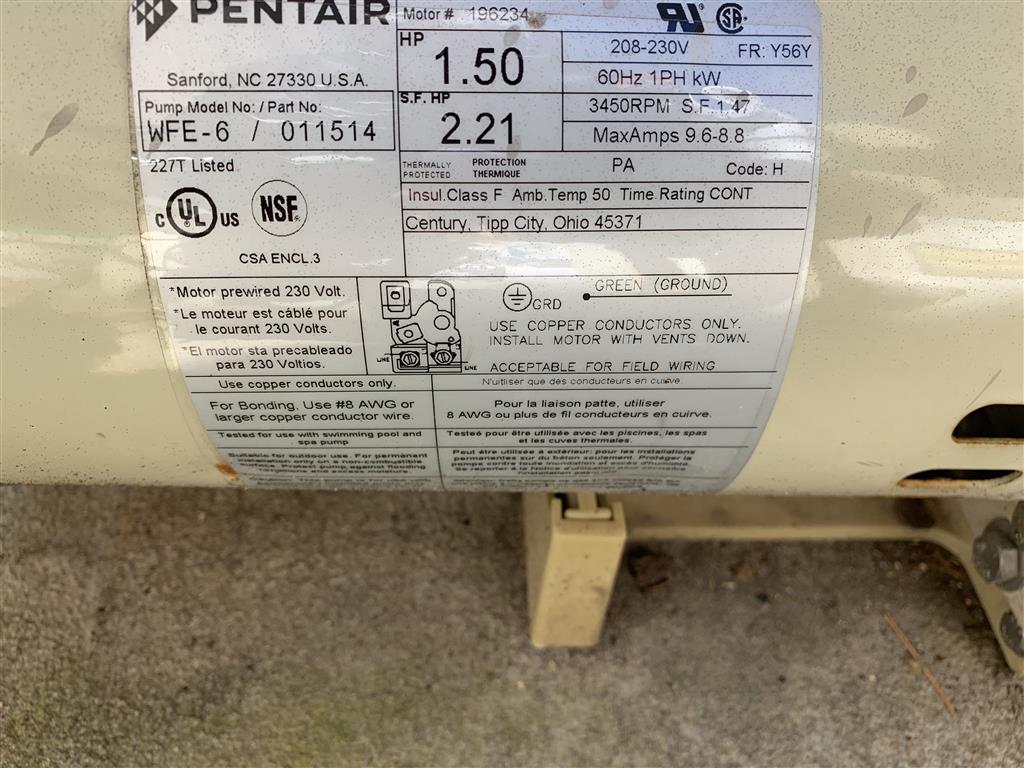

This thread is for me to work out what I do in upgrading my 20 year old pool equipment. Jandy RS8 automation, 1.5HP SS Pentair pump, Pentair Mastertemp 400 NG heater, IC40 SWG, typical pool/spa combo with spa spillover, Pentair JVA actuators on suctions & return Jandy valves, 1HP pump for spa jets, Polaris 380 pressure cleaner with booster pump, air blower, control panel in house and by spa.

@MyAZPool Please confirm that the Pentair Intellivalves that come with the Intellicenter are just actuators and just bolt on the top of Jandy valves? They are not real valves that you need to plumb into.

My thinking right now is to replace the Jandy RS8 with the Intellicenter and my pump with the Intelliflo 011028.

I think I will get the Intellicenter 8 - I8PSIC60 - bundle that includes the Intellivalves and the IC60. My IC40 is a few years old and undersized for my 35K pool. So I can drop in the IC60 and have the IC40 as a spare. I will also get the Indoor control Panel and the Spa Command Controller.

My relay setup will be:

1 - Filter Pump

2 - Spa Jet pump

3 - Air Blower

4 - Polaris cleaner pump

5 - Pool Light

6 - Maybe equipment pad light

I need the Comm Port expansion board to connect to:

- 2 Intellivalves

- SWG

- Mastertemp heater

- Intelliflo pump

Current Jandy panel and pump pic is below.

@MyAZPool Please confirm that the Pentair Intellivalves that come with the Intellicenter are just actuators and just bolt on the top of Jandy valves? They are not real valves that you need to plumb into.

My thinking right now is to replace the Jandy RS8 with the Intellicenter and my pump with the Intelliflo 011028.

I think I will get the Intellicenter 8 - I8PSIC60 - bundle that includes the Intellivalves and the IC60. My IC40 is a few years old and undersized for my 35K pool. So I can drop in the IC60 and have the IC40 as a spare. I will also get the Indoor control Panel and the Spa Command Controller.

My relay setup will be:

1 - Filter Pump

2 - Spa Jet pump

3 - Air Blower

4 - Polaris cleaner pump

5 - Pool Light

6 - Maybe equipment pad light

I need the Comm Port expansion board to connect to:

- 2 Intellivalves

- SWG

- Mastertemp heater

- Intelliflo pump

Current Jandy panel and pump pic is below.

now. Thanks!!

now. Thanks!!

Very nice!!

Very nice!!