How to Close a Pool for the Winter

How to Close an Above Ground Pool

Closing your Above Ground Pool in TFP Pool School.

How to Close an In-Ground Pool

Closing Your In-Ground Pool in TFP Pool School.

The concept of closing an in ground swimming pool

Winterizing Paramount's In-Floor Cleaning System.

How To Use Polyquat 60 in Pool Winterization

How To Use Polyquat 60 in Pool Winterization?

Connecting Air Through Pump

Modified Pump Cover to Connect Blower for Closing Swimming Pool

A modified pool pump cover can be used to connect the air output from a blower to the plumbing. These modified covers are custom made.

Few tips when making your modified cover:[1]

- Go very slow or you will bind up.

- Clamp it down or it will go for a spin.

- If you order a new lid, use it for the pump and use old one for the modifications.

- Do not not use silicone unless absolutely necessary. The fittings that go thru the lid will have rubber gaskets that would seal it.

- Make sure you get the correct 6' hose.

Modified Cover for Hayward Super Pump for Closing Swimming Pool gives more details on the process.

Connecting Compressor to Pump Using Drain Port

A compressor can be connected to the 1/4” npt drain port of the pump to blow air into the suction and return lines.

You can then isolate the suction and return side with winter plugs. Plug the return side and work on the suction side. Then plug the suction side and work on the return side.[2]

Remove the lid and inside you will have the ports where the plumbing is attached, both suction and the return side. The suction (Main Drain and Skimmers are toward the shut off valve). The back is the return side. The plugs that will fit are either #8, #9, #10 or # 11. Plug the port inside the housing. Only plug the side you want air NOT to travel.

Or you can use the shut off valves to close off the air traveling towards the skimmers & main drain, but the winter plugs work best. No need to over tighten either, just snug as they are not going anywhere.

How Much Air is Required to Blow Out Lines?

Low pressure and high volume is best to blowing air through the lines. You only need 3.5 psi to clear a pipe 8 ft below water level.

Bursting due to air pressure is a non-issue. Typical 2" plumbing has a bursting pressure of 890 psi. Glue joints, if done properly should be just as strong if not stronger than the pipe itself because of the double thickness of the pipe wall at the joint.[3]

Techniques to Air Lock the Main Drain

Winterizing the main drain, if you have one, depends on the way the main drain is plumbed into your system. You do not, and cannot, clear the main drain of water. What you want to do is clear the water down the pipe until close to or at the frost level. That gives a free column for any water and ice to expand into.

Valves

If your main drain has its own valve it should be air locked with the shut off valve and then the air compressor immediately shut off.

First shut off the main drain to clear skimmers. When done, close skimmers with valve and clear main drain. After bubbling, shut off main drain and then shut off the compressor to not create back pressure.

Foam Rope

If the main drain is connected to a hole in a skimmer you can push a 4’ piece of foam rope into the hole and be done with it.[4] It takes patience and good fingers to push against the water pressure. Then plug the hole with the foam rope in. Hold the plug down with your pinky while using thumb and index to push the rope in.

Winterizing the Skimmer

Once the skimmer lines are blown out the objective is to displace water from the skimmer so that if ice forms in it the ice has room to expand up. Ice does not expand more than 9% and will go upward in the skimmer.[5]

People fill the skimmer with one or more of the methods below.

Gizzmos

There are various size Gizzmos for in-ground and above ground pool skimmers. The Gizmo screws into the skimmer line. There are many products similar to the Gizzmo for absorbing the expansion of ice in the skimmer.

The Gizzmo needs teflon tape on the threads to seal well.

Some Gizzmos have a a blowout valve on the top in the top to blow out lines. If you have a Gizzmo that has an opening at the top and air is coming out of the threaded area, then the threads on the Gizmo may be stripped.

Pool Noodles

- pool noodles are made from closed cell foam which doesn't absorb water.

- put 6" of "pool noodle" in the skimmer, just in case rain, snow, etc fills the pool back up

- Cut a 8 inch piece off the end of a noodle. Place it in skimmer.[6]

- If you use pieces of pool noodles along with the Gizzmo's, wrap them around the Gizzmo in a circular fashion. The more you cover, the less water, which means more protection.

Plastic Bottles

- one liter plastic bottle filled up half way with antifreeze is fine

- drop into the skimmers a plastic water bottle filled half way with windshield washer fluid.

- use a gallon jug of Antifreeze with about 1/4 left in the jug. It fits in a skimmer perfect, and add a little antifreeze to the skimmer box

Winterization Plugs

Winterizing plugs are used to seal the return and skimmer holes. They can also be used to plug the pump intake and outlet and individual lines during the blowout process.

Rubber Expansion Plugs

Tapered rubber winter expansion plugs with a wingnut to tighten come in various sized:

- 0 - 1/2" pipe tapered

- 1 - 1/2" pipe

- 2 - 3/4" tube tapered

- 3 - 3/4" pipe

- 4 - 3/4" and 1" pipe

- 5 - 1" pipe

- 6 - 1" fitting

- 7 - 1 1/4" pipe tapered

- 8 - 1 1/2" pipe tapered

- 9 - 1 1/2" pipe and 1 1/4" fitting tapered

- 10 - 1 1/2" fitting tapered

- 11 - 2" pipe

- 15 - 4" pipe

- 16 - 4" pipe

There are also extra long tapered plugs that can cover #7 to #10 sizes.

Blow-Thru Valve Winter Pool Plugs

Blow-Thru Valve Winter Pool Plugs are tapered rubber plugs with a Schrader valve stem.

Most members with an air compressor usually connect an NPT fitting to the pump basket, then clear the lines with an air compressor, or they create some adapter and work from the skimmers, unions, etc. If you are working on the return side, this would mean that you will have to isolate the suction side to create enough air volume to accomplish the task and vice versa.[7]

With the blow thru plugs, one can simply place in a the pump basket housing, and use an air compressor to move water with air. This method would only require 2 plugs and an air compressor (One on the return side and one on the suction side)

They are also useful for blowing out pipes, such as a main drain, where you don’t have a valve.

Threaded Return Line Plugs

A threaded plug with an O ring will screw into return lines to seal them for the winter. It is the Hayward SP1022C 1.5" MPT Plug with O-Ring, White with similar plugs from other manufacturers.

The threaded plugs fit 1 1/2" return fittings. The Hayward SP1419T seat removal tool will remove the directional fitting to plug it during winterization.

Use Teflon tape on the threads and Pool Lube on the O ring.

This 1 1/2" threaded plug can also replace the drain plug in XtremepowerUS, Hayward and Pentair filter tanks

Winter Duck Plugs

Winter Duck Plug (fits 1-1/2" Threads) is a one-way pool "duck-bill" valve allowing a large flow of air and water to be blown from the return plumbing but does not allow water back into the lines.

The double-seal system provides a water tight seal at the face plate or inside the fitting. The Winter Duck Plug provides adequate back pressure to allow all returns to be cleared at the same time without "burping." Once all the returns have been bubbling for several minutes you turn off the blower. Water will not enter the pipes from the pool.[8]

Bungee-Plug

The Bungee-Plug is a one-way valve with a bungee strap that stretches to allow air or water to flow freely when pressure is applied. The bungee strap responds instantly to pressure relief and seals with a unique triple O-ring seal.

The Bungee-Plug replaces the return eyeball, and there's a hole in the center that's plugged with a rubber stopper that's held in place by a strap coming off of the back of it. When you blow air through the system, the strap stretches allowing air to exit. As soon as the pressure is removed from the backside, the strap contracts, and the hole is plugged, sealing the return from water.[9]

Removing the Filter Pressure Gauge

Depending on the type of oil/filler in the gauge, often times they get stuck or their calibration gets thrown off. TFTestkits has very good glycerin-filled gauges that is freeze protected to -4º F.

Even then, it's easy to be safe and unscrew the gauge during closing, then just re-attach it in the spring with a 2-3 wraps of Teflon tape.[10]

What can happen is that a small amount of water gets into the bourdon tube and due to the orientation of the gauge (especially back mount gauges) it doesn't drain out so during a freeze. The water freezes and deforms the tube causing the gauge to read incorrectly or not at all. This is especially true for back mounted gauges mounted vertically.[11]

Some filters use back mounted gauges mounted horizontally recessed into the top housing and those aren't as susceptible to holding water in them. Also, bottom mounted gauges mounted vertically nipple down, aren't as prone to holding water in them.

Some pressure gauges are cheap and can be replaced in the spring. Removed or not the cheap ones rarely last a year.[12]

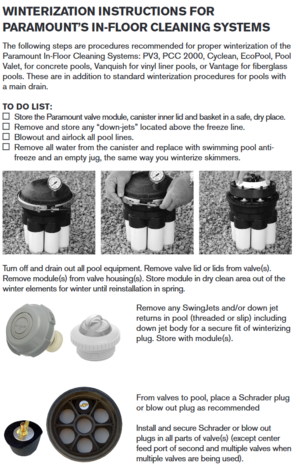

Winterizing Paramount In-Floor Cleaning system

Manuals for the IFCS and other Paramount products are at Winterizing Proceedures For: Paramount Pool Products and WINTERIZATION INSTRUCTIONS FOR PARAMOUNT’S IN-FLOOR CLEANING SYSTEMS

Paramount makes a proprietary shaped cylindrical plug with one flat side to fit the water valve with schrader valve - Paramount Set of 1-1/2" or 2" Winterizing Plugs (6 Pack) 004-302-1672-00.

This thread has a discussion about closing the Paramount IFCS.

- Turn off and drain out all pool equipment. Remove valve lid or lids from valve(s). Remove module(s) from valve housing(s). Store module in dry clean area out of the winter elements for winter until reinstallation in spring.

- Remove any SwingJets and/or down jet returns in pool (threaded or slip) including down jet body for a secure fit of winterizing plug. Store with module(s).

- From valves to pool, place a Schrader plug or blow out plug as recommended

- Install and secure Schrader or blow out plugs in all parts of valve(s) (except center feed port of second and multiple valves when multiple valves are being used

- Proceed to blow out lines through Schrader or blow out plugs to pool.

- While blowing out the in-floor nozzles, once a good amount of air has come through the nozzle, you have accomplished an air lock. (This procedure is similar to obtaining an air lock when blowing out the bottom drain in the pool.)

- Blow out center port of first valve back to filter equipment and plug.

- While blowing out the down jets and while air is escaping through the in-wall hole, install and secure a regular winterizing plug.

- Repeat until all ports are blown out.In cases where multiple valves are in use, blow out the feeder port of the first valve into the center port of the second or multiple valve(s), install, and secure plug.

- When necessary, pool winter anti-freeze solution should be poured into each line.

- Valve housing(s) should be wiped clean and dry of water, reinstall top lid and secure

Tips

- Look at the water valve risers for pipe size & check for reducers/bushings[13]

- Don't be a cheapskate & grind down a schrader plug, it will fall down the pipe

- You will need to remove the floor heads for those that are too shallow to airlock & insert #12, for these a cyclone will do since they get plugged

- Buy the paramount removal wrench, a couple seasons removing with improvised tools & heads will be mangled

- For the deeper ports that must be airlocked, compressor is mandatory. Pour a little antifreeze on top of plug, to make sure no bubbles- usually takes about 4 cranks beyond hand tight to seal these plugs

- That will get you through the paramount pressure side, if you have a true system there is more fun to be had on the suction side of this

- Getting into features like these it's best to have a pro do it

- These repairs are big bucks & failures are discovered at apex of the busy season

Closing Pool With an Autocover

Auto-covers are designed to rest on the pool water. You will damage the auto-cover if you drain the pool and close the auto-cover.[14]

If you are going to drain, you must fully open the auto-cover and use a separate winter cover for the off season.

Plugging the Skimmer Door

If you blow out the skimmer line and need to leave the water up to the skimmer due to water supporting the cover or a vinyl liner then use a skimmer plug or an aquadoor skimmer faceplate to close off the skimmer.[15]

When do Pipes Begin Freezing

Read The Physics of Freezing and Freeze Protection.

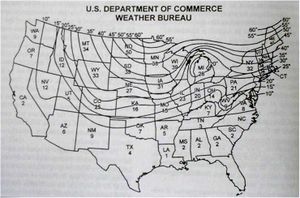

What Depth is Safe From Freezing

Consult the Frost Line map for your area.

Ice Shelves

- ↑ https://www.troublefreepool.com/threads/hayward-modified-pool-pump-cover-for-closing.194854/post-1717848

- ↑ https://www.troublefreepool.com/threads/closing-from-the-pump-with-compressor-need-help-on-a-few-items-please.195129/post-1719869

- ↑ https://www.troublefreepool.com/threads/blowing-out-main-drain-friendly-debate.107407/post-941666

- ↑ https://www.troublefreepool.com/threads/air-lock-on-main-drain.194948/post-1718724

- ↑ https://www.troublefreepool.com/threads/help-needed-winterize-inground-pool-skimmer.195126/post-1719867

- ↑ https://www.troublefreepool.com/threads/pool-noodle-and-skimmer.129875/post-1148109

- ↑ https://www.troublefreepool.com/threads/blow-thru-valve-winter-pool-plugs.174703/

- ↑ https://www.leaktools.com/winter-duck-plug-fits-1-12-threads.html

- ↑ https://www.troublefreepool.com/threads/bungee-plugs-anyone-ever-used-these.153172/post-1354700

- ↑ https://www.troublefreepool.com/threads/remove-gage-when-closing.195301/post-1721607

- ↑ https://www.troublefreepool.com/threads/remove-gage-when-closing.195301/post-1721661

- ↑ https://www.troublefreepool.com/threads/remove-gage-when-closing.195301/post-1721668

- ↑ https://www.troublefreepool.com/threads/safety-cover-and-water-levels.153612/post-1359997

- ↑ https://www.troublefreepool.com/threads/drain-water-with-automatic-cover.194370/post-1713556

- ↑ https://www.troublefreepool.com/threads/drain-water-with-automatic-cover.194370/post-1722623