Hey there all I began experiencing a strange issue with my Raypak RP2100 336K heater. This is an old heater with the analog display so I can't see a code to narrow the issue down. Three months ago I replaced the PC board, thermometer sensor, high limit switches, thermal fuse, and the water pressure switch. I finally figured out the issue was with the thermometer sensor had rainwater in the well which was heating up really quickly and causing the heater to trip off and the service light would come on. Cleaned out the water and the old thermal paste with new and I was working perfectly for the past 3 months. This was after a Raypak certified technician came to my house and told me... "Hmmm I think it's the motherboard but I'll have to buy a digital one and retrofit it, so it will probably be $1,000 and then I still guarantee that is the issue so if it doesn't work, you'll be out the money." The new issue I've been experiencing is the heater fires up perfectly and runs for approximately 45 mins and then the flame goes out and I can hear the ignition clicking attempting to restart the pilot but to no avail. During that time the spa temp went from 66F to 87F. If I kill the power and reset the heater and attempt to refire, the ignition continues to click but no flame ignites. If I turn off the heater, I can restart it in about 2 hours and it will run perfectly for another 45 mins until the same issue happens again. Gas line is fully open and Honeywell gas valve is set to the on position. I don't believe this is flame roll out due to the fact that the thermal fuse has continuity, no wind or rain, and the heat exchanger is clean of carbon or leaves. Not super educated on pilots/ gas furnaces but I've been watching videos trying to educate myself. I'm pretty handy and fix pretty much anything myself without issue with the help of youtube university lol. I haven't pulled out the lower tray and cleaned the gas orifices yet but was wondering if you guys can possibly help identify this issue before I get in there and start investigating. Much appreciated!

Raypak RP2100 Flame rollout issue

- Thread starter kh2456

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Jul 21, 2013

- 65,396

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Check the pilot assembly. It sounds to me like you are losing the flame sensing.

@swamprat69 may have ideas.

@swamprat69 may have ideas.

Will do thank you!Check the pilot assembly. It sounds to me like you are losing the flame sensing.

@swamprat69 may have ideas.

Flame roll out would show as a burned/sooted area in the cabinet, especially near the left side where the roll-out "switch" is located. They are actually a one-time-use fuse. If they go out they must me replaced, not reset. The condition you describe does not appear to be roll out.Hey there all I began experiencing a strange issue with my Raypak RP2100 336K heater. This is an old heater with the analog display so I can't see a code to narrow the issue down. Three months ago I replaced the PC board, thermometer sensor, high limit switches, thermal fuse, and the water pressure switch. I finally figured out the issue was with the thermometer sensor had rainwater in the well which was heating up really quickly and causing the heater to trip off and the service light would come on. Cleaned out the water and the old thermal paste with new and I was working perfectly for the past 3 months. This was after a Raypak certified technician came to my house and told me... "Hmmm I think it's the motherboard but I'll have to buy a digital one and retrofit it, so it will probably be $1,000 and then I still guarantee that is the issue so if it doesn't work, you'll be out the money." The new issue I've been experiencing is the heater fires up perfectly and runs for approximately 45 mins and then the flame goes out and I can hear the ignition clicking attempting to restart the pilot but to no avail. During that time the spa temp went from 66F to 87F. If I kill the power and reset the heater and attempt to refire, the ignition continues to click but no flame ignites. If I turn off the heater, I can restart it in about 2 hours and it will run perfectly for another 45 mins until the same issue happens again. Gas line is fully open and Honeywell gas valve is set to the on position. I don't believe this is flame roll out due to the fact that the thermal fuse has continuity, no wind or rain, and the heat exchanger is clean of carbon or leaves. Not super educated on pilots/ gas furnaces but I've been watching videos trying to educate myself. I'm pretty handy and fix pretty much anything myself without issue with the help of youtube university lol. I haven't pulled out the lower tray and cleaned the gas orifices yet but was wondering if you guys can possibly help identify this issue before I get in there and start investigating. Much appreciated!

With a small mirror, the next time you experienced the issue try to see if the pilot is actually lit even though the ignitor continues to spark. If so, get a new pilot burner assembly. You can try cleaning the small "fork" above the actual pilot flame, that is the flame-sense area but on a heater that old a replacement is best. Also, be sure there is a good ground between the burner tray and the cabinet, even if it means adding a small wire between one of the screws that hold the tray in place and a clean screw in the cabinet.

Looks like your were pretty accurate and I need a new pilot assembly. It’s a tad shot out hahaFlame roll out would show as a burned/sooted area in the cabinet, especially near the left side where the roll-out "switch" is located. They are actually a one-time-use fuse. If they go out they must me replaced, not reset. The condition you describe does not appear to be roll out.

With a small mirror, the next time you experienced the issue try to see if the pilot is actually lit even though the ignitor continues to spark. If so, get a new pilot burner assembly. You can try cleaning the small "fork" above the actual pilot flame, that is the flame-sense area but on a heater that old a replacement is best. Also, be sure there is a good ground between the burner tray and the cabinet, even if it means adding a small wire between one of the screws that hold the tray in place and a clean screw in the cabinet.

I also checked and the pilot is not lit when the igniter is attempting to start. No flame from burners or pilot.

- Jul 21, 2013

- 65,396

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

If the flame sensor is defective and no flame is sensed the gas valve is shut.I also checked and the pilot is not lit when the igniter is attempting to start. No flame from burners or pilot.

Roger that. Seems like that is the issue. Ordered a new bracket and pilot assembly today. Will report back once installed. Thank you for the help.If the flame sensor is defective and no flame is sensed the gas valve is shut.

There is so much corrosion on that burner assembly that the tiny orifice could be corroded shut (blocked).I also checked and the pilot is not lit when the igniter is attempting to start. No flame from burners or pilot.

I’m planning on removing the burner tray to do a thorough cleaning of the orfices. Any recommendations on how to remove the piping? I circled where the first attachment point is I’m going to loosen to remove it but given the design and hole I’ll probably have to remove the pipe entering into the gas valve? Let me know what you think.There is so much corrosion on that burner assembly that the tiny orifice could be corroded shut (blocked).

Yes, the pipe to the gas valve has to be removed. Given how tightly that equipment is plumbed, you might have to remove the water connections to move the heater enough to get the pipe out of the gas valve. Also, all the corrosion on the gas valve indicates it should be replaced as well. All the rust on the bottom of the heater means that, when you remove the burner tray you may find that the cabinet is rusted completely through. That is an OLD heater that likely should be replaced. As much as I hate telling a customer this, if I was called out to service it I would have to decline. I can't put a gas appliance with that much damage back into service without incurring a lot of liability.I’m planning on removing the burner tray to do a thorough cleaning of the orfices. Any recommendations on how to remove the piping? I circled where the first attachment point is I’m going to loosen to remove it but given the design and hole I’ll probably have to remove the pipe entering into the gas valve? Let me know what you think. View attachment 483028View attachment 483029View attachment 483029View attachment 483029

You’re 100% right and it’s definitely shot out. Just was looking to prolong it for as long as possible but guess it’s time to bite the bullet.Yes, the pipe to the gas valve has to be removed. Given how tightly that equipment is plumbed, you might have to remove the water connections to move the heater enough to get the pipe out of the gas valve. Also, all the corrosion on the gas valve indicates it should be replaced as well. All the rust on the bottom of the heater means that, when you remove the burner tray you may find that the cabinet is rusted completely through. That is an OLD heater that likely should be replaced. As much as I hate telling a customer this, if I was called out to service it I would have to decline. I can't put a gas appliance with that much damage back into service without incurring a lot of liability.

I replaced the gas valve and pilot assembly. I'm getting 24 volts to the gas valve when it calls for heat, so the motherboard is good. Pilot is flaming well but nothing from the main burners. I cleaned all the orifices with a wire brush. I'm lost on where to attempt to diagnose this any further.

You're getting 24V at the pilot portion of the valve. Did you install a new pilot burner? Does the sparking stop? If not it is not sensing flame. You can clean the "fork" on the used pilot burner. Use a Scotch Brite or better a new dollar bill (yep, they work) so as to not remove too much of the protective coating. Also, you may need to run a new ground wire from one of the screws holding the burner tray in place to a clean screw on the cabinet.I replaced the gas valve and pilot assembly. I'm getting 24 volts to the gas valve when it calls for heat, so the motherboard is good. Pilot is flaming well but nothing from the main burners. I cleaned all the orifices with a wire brush. I'm lost on where to attempt to diagnose this any further.

If the sparking does stop, you need to check the other connection, should be marked MV. If it is getting power that valve is bad. It does happen on occasion that even a new valve doesn't work.

Thanks for the reply, yes the pilot assembly and bracket is brand new. The sparking does not stop so you're not right about it not sensing the flame. If it's not sensing flame, I assume the new pilot assembly is bad? It was probably not OEM because I ordered from amazon. Pilot flame looks strong and blue though. Can you explain in detail to me like I'm stupid about running a new negative wire from the tray to the cabinet? What does this negative provide grounding for? Not questioning would just like to know for knowledge. Where would be a good location on the cabinet? Should I use one of the bolt locations that hold the tray to the ground? When I cleaned out the burner tray I noticed that it had a lot of rust. Would this affect this ground? I ordered a 24v transformer to artificially jump/provide power to the MV and PV just to see if the valve is in fact functioning properly.You're getting 24V at the pilot portion of the valve. Did you install a new pilot burner? Does the sparking stop? If not it is not sensing flame. You can clean the "fork" on the used pilot burner. Use a Scotch Brite or better a new dollar bill (yep, they work) so as to not remove too much of the protective coating. Also, you may need to run a new ground wire from one of the screws holding the burner tray in place to a clean screw on the cabinet.

If the sparking does stop, you need to check the other connection, should be marked MV. If it is getting power that valve is bad. It does happen on occasion that even a new valve doesn't work.

A small current is sent through the ignition wire along with the spark. Flame conducts electricity. There has to be a good ground so that small current will actually flow and the current is sensed by the ignition control board. No ground=no flame sensing=continued sparking as control doesn't sense the pilot is lit=ignition sequence will not proceed to open the new valve.Thanks for the reply, yes the pilot assembly and bracket is brand new. The sparking does not stop so you're not right about it not sensing the flame. If it's not sensing flame, I assume the new pilot assembly is bad? It was probably not OEM because I ordered from amazon. Pilot flame looks strong and blue though. Can you explain in detail to me like I'm stupid about running a new negative wire from the tray to the cabinet? What does this negative provide grounding for? Not questioning would just like to know for knowledge. Where would be a good location on the cabinet? Should I use one of the bolt locations that hold the tray to the ground? When I cleaned out the burner tray I noticed that it had a lot of rust. Would this affect this ground? I ordered a 24v transformer to artificially jump/provide power to the MV and PV just to see if the valve is in fact functioning properly.

Please, don't operate the heater with a separate power source to the main valve as you will have bypassed all the safety devices in the heater. Continued sparking means the system has never tried to open the main valve, not that the valve is bad.

There are many posts on this forum that explain how it works.

Roger that thank you for your help. I will run a new ground and continue down the rabbit hole.A small current is sent through the ignition wire along with the spark. Flame conducts electricity. There has to be a good ground so that small current will actually flow and the current is sensed by the ignition control board. No ground=no flame sensing=continued sparking as control doesn't sense the pilot is lit=ignition sequence will not proceed to open the new valve.

Please, don't operate the heater with a separate power source to the main valve as you will have bypassed all the safety devices in the heater. Continued sparking means the system has never tried to open the main valve, not that the valve is bad.

There are many posts on this forum that explain how it works.

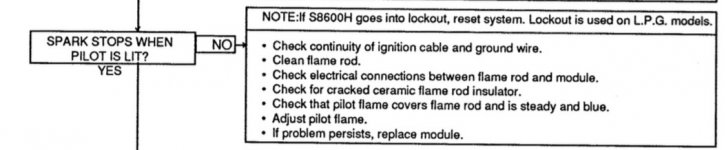

So I added an additional ground to chassis with no change. After watching multiple HVAC YouTube pros this is definitely a flame rectification issue. I followed the manual troubleshooting and checked the ignition cable to ground and it reads OL with no continuity. I tested this with power off. Very confused because this new pilot assembly is only 2 weeks old…?A small current is sent through the ignition wire along with the spark. Flame conducts electricity. There has to be a good ground so that small current will actually flow and the current is sensed by the ignition control board. No ground=no flame sensing=continued sparking as control doesn't sense the pilot is lit=ignition sequence will not proceed to open the new valve.

Please, don't operate the heater with a separate power source to the main valve as you will have bypassed all the safety devices in the heater. Continued sparking means the system has never tried to open the main valve, not that the valve is bad.

There are many posts on this forum that explain how it works.

Attachments

swamprat69

Well-known member

The ignition cable only has continuity to ground when there is a flame present. The flow of electricity is through the flame.

swamprat69

Well-known member

Continuity of the ignition cable is from the rod (electrode/sparker) to the connector at the other and of the ignition cable. Continuity of the ground wire is from the pronged pilot hood to case ground with the pilot assembly in place.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.