So, it’s been almost about a month now, since I received the Pentair IntelliCenter Control System automation equipment and “let the fun begin”. I thought that I might share my experiences and my opinions up to this point, in case others may be considering the purchase and use of this particular automation system in the future. I realize that a month is not very long, but with the amount of time that I have spent “holding-hands” with the IntelliCenter during that month (and the time I spent with my nose buried in the various user and installation guides), I feel I have become somewhat of an SME on the subject.

I have attempted to comply with the TFP Guidelines for Posting Reviews, while drafting this particular review and I am not promoting nor am I advising against, the use of the Pentair IntelliCenter Control System, or any other automation system for that matter. I have attempted to be fair and honest in my assessments of this particular automation system, based upon my own personal experiences up to this point.

I will update this thread as time goes on, as I work with Pentair on some “bug” issues and if I discover new and relevant information regarding the installation and use of the Pentair IntelliCenter Control System.

Background:

Earlier in the year, I had decided to completely renovate and update my pool equipment pad. I spent many hours on the computer (especially here on TFP) doing lots of research on advanced plumbing techniques, equipment specifications, automation integration, etc.

IntelliCenter still had not been released at the time I decided to get started (July). After some online research and contacting one of the local Pentair reps, it was determined that if I installed a Pentair IntelliTouch/EasyTouch Load Center, that I could then convert it to IntelliCenter later, once the newer automation system was released. Great! I could at least get a head start and get the electrical laid in, and then I could decide later on whether to go with the IntelliCenter Control System or one of the other Pentair automation systems.

So I ordered ONLY the IntelliTouch/EasyTouch Load Center at that time and started digging. I retrenched (ouch - 18” deep) from the equipment pad location about 120 feet to the house electrical service entrance. I laid in new 60 amp service to the new Pentair Load Center (good thing my neighbor is a commercial electrical contractor). He gave me all the advice I needed and then helped me with the “pull” through the conduit). But he sure didn't help me dig

I was now ready for the automation. I had been advised by some, to maybe think twice about the IntelliCenter and possibly consider opting with the tried and true ScreenLogic type systems (IntelliTouch or EasyTouch), since the IntelliCenter was still so new and not much was known about it at that time. This advice was certainly sound, based on information available at the time and based on their past experiences, but after some exhaustive research and willing to "jump-in" and take a chance, I was determined to move ahead with the IntelliCenter integration anyway.

My decision towards IntelliCenter versus the ScreenLogic type automation systems was based on many factors, some of which I have outlined below, others that I have chosen to keep to myself due to the fact that I respect everyone’s decision to choose their own type of automation system based on their own personal preferences and their particular needs and requirements.

1. Newer technology and the capacity for further enhancements in the future.

2. Web Based (no need for configurator type utilities and programs).

3. Since I greatly prefer wired connectivity (when available) versus wireless (for a myriad of reasons), I could “lay-in” Cat5E to the equipment pad and just “plug and play”, due to the onboard ethernet port (built-in connectivity) located on the IntelliCenter Control System Main Circuit Board. (I ran a 1” conduit using grey electrical pvc, from the side of the house (attic) to a low voltage raceway “knockout” and pulled in the Cat-5E).

4. Automatic software and firmware update “pushes” versus the “flash-upgrade” style updates that I understand requires an expensive Pentair Automation Flash Programming Kit.

5. Future expandability, flexibility and upgradeability (i.e. future RS-485 support for IntelliValve and possibly IntellipH as well).

6. USB port which allows for saving the latest system configuration file. (i.e. If experimenting with a new System Configuration, Schedules, Features, Feature Groups (macros), etc. and I goof something up, I can always revert back to the last saved config file and start over).

7. No real cost difference from other similar systems due to several factors that I will not elaborate on here.

8. Built-in integration support for the new Pentair IntelliFlo VSF pump (011056) (which I had opted for and installed) or the Pentair IntelliFloXF VSF pump (022056).

9. Built-in integration support for the new Pentair IntelliValve (two come bundled with the personality kits).

10. Larger Capacitive type screen which is touch sensitive, and which would allow me better access to ALL functionality at the equipment pad (when preferred or required).

11. 32 “Feature Circuits” capability.

12. 16 “Feature Groups” (“macros”) capability.

13. A whopping 100 available "Schedules".

I was told by Pentair Tech Support and authorized Pentair dealers that were offering the IntelliCenter, that I would need the Pentair IntelliCenter upgrade/retrofit kit, and that it would not be released until the March 2019 time frame. But I forged ahead anyway and continued conducting my own research on IntelliCenter, in order learn as much as I could about the newer automation system.

I contacted the local Pentair rep again. After some research on their part, I was told that I DID NOT in fact, have to wait for the upgrade kit. I was told that what I needed was just the i5PS personality kit (521912), the IntelliCenter System Transformer kit (522102Z) and because I was going to incorporate six valve actuators with the automation (the personality kit will only allow for four), that I needed the Valve Expansion module (522038Z) (I already knew about this one). All of this made sense to me but I was a little nervous about the whole affair, since it appeared that I was now being the “guinea pig” with all of this, since it was so “new”

Okay, so I took a deep breath, grabbed the VISA card and called PolyTec pools and proceeded to place my order. By this time, I had decided on the IntellipH versus the IntelliChem, due to my research and the good and sound advice I believe, that I received from other members here on TFP. So I also ordered that (the ipH) as well, along with four additional Pentair IntelliValves. (again, the personality kit includes two IntelliValves).

Converting the IntelliTouch/EasyTouch Load or Power Center for IntelliCenter: (The following is NOT applicable for those future IntelliCenter users that do not already have an IntelliTouch or EasyTouch Load/Power Center that they are converting to IntelliCenter!

The first thing I needed to do was to convert my IntelliTouch Load Center to accept the IntelliCenter. That meant the removal and replacement (r&r) of the system transformer and some of the low voltage circuit breakers.

The only difference that I can tell between the IntelliTouch/EasyTouch system transformer and the new IntelliCenter system transformer is that the low voltage circuit breaker wiring harness is different (the voltage and amperage specifications are the same as far as I can tell), however it does look different and feels heavier.

Note: When purchasing the IntelliCenter System Transformer kit (522102Z), the kit will include the transformer, mounting hardware and the two new 18V-5A and 24V-4A low voltage circuit breakers that are required to replace the older low voltage circuit breakers.

The IntelliTouch/EasyTouch Load/Power Centers utilize three (3), 3-amp system low voltage circuit breakers (along with the optional grey SWCG 24Vac, 12A breaker). These are for the following:

Electronics: 12V, 3A

Valves: 24V, 3A

Relays: 18V, 3A

The IntelliCenter utilizes only two (2) low voltage circuit breakers (also along with the optional grey SWCG 24Vac, 12A breaker).

These are for the following:

Electronics: 18V, 5A

Valves 24V, 4A

Relays: NONE (different type of circuitry I assume)

Removing and replacing the system transformer and the low voltage circuit breakers, was not too bad of a chore but it was a bit time consuming, as I was taking my time with it, so as to not “break” anything, and since no instructions were included in the kit.

WARNING: You should always remove power from the Load/Power Center at the main circuit breaker panel/service entrance circuit breaker that feeds power to the Load/Power Center, before removing the high voltage cover panel (dead front). If you are not completely comfortable or confident in your abilities to do this type of work, I highly suggest that you consult with and hire a licensed and experienced professional who is.

1. Once you have removed power from the Load Center/Power Center, remove the Load/Power Center high voltage cover panel (dead front). Can you figure out why it’s nicknamed a “dead front”?

2. Disconnect the appropriate line power leads from the system transformer to the breaker.

3. Unplug the connector that is connected to the older system board that is attached to the system transformer (I did not have to do this, since I only had the load center and no other system board yet) and unplug the connectors at the back of the low voltage circuit breakers (insure that you note what color of wires you are unplugging from which circuit breakers so you know what goes where, when you replace these connections with the newer circuit breakers).

4. Remove the four transformer mounting screws and remove the system transformer.

5. You will then have to completely remove the low voltage circuit breaker housing mount (a bit of a pain but do-able).

6. Remove the three (3) old low voltage circuit breakers from the mount and replace with the two (2) new low voltage circuit breakers in the low voltage circuit breaker housing mount.

7. Install the new IntelliCenter System Transformer in the Load/Power Center.

8. Install the low voltage circuit breaker housing mount in the Load/Power Center.

9. Re-connect the appropriate line power leads from the system transformer to the applicable circuit breaker (120Vac or 240Vac).

10. Replace the Load/Power Center high voltage cover panel (dead front).

11. Return power back to the Load/Power Center at the main service entrance HOWEVER, ensure that the breaker that supplies power to the system transformer is in the OFF position for the moment before proceeding.

You are now ready to mount the IntelliCenter System Board in the Load Center. However, in my case, I had to attach the optional Valve Expansion module (522038Z) to the System Board first. It’s very easy, but a word of warning here. You are handling circuit boards which are very receptive to damage from static electricity. Ensure that you take the necessary precautions recommended to eliminate the possibility of static electricity damage to the circuit boards.

Attach the connector from the Control System Transformer cable to the Circuit board/Touch screen assembly.

Energize the circuit by placing the applicable circuit breaker back to the ON position.

Initial Power-up and Setup Wizard:

Once power is applied to the IntelliCenter Control System, the system will perform an initial power-up sequence and you will be presented with a Pentair End User License Agreement, which you have to scroll down through and then tap the I Accept button to proceed. This will occur only once, at the initial power-up.

I highly recommend that the Setup Wizard be utilized in order to get started. To start the Setup Wizard from the home screen, tap Settings > Advanced System Configuration > Wizard. I found using the wizard easy and it basically walks you through all the steps in order to configure all of the basic setup items to include the Network and WiFi (if applicable) setups. You can skip items that you want to come back to later.

Once the network configurations are completed, all other General, Advanced System Configurations, Circuit, Feature Circuit, Circuit Groups, Chemistry Control, Other Equipment (Valves, Heaters & Covers), Pumps and Remote(s) (If applicable) configurations and settings can be completed using one of several user interfaces.

User Interfaces:

There are several user interfaces available to control and/or configure IntelliCenter.

1. The IntelliCenter Control System Outdoor Control Panel (obviously).

2. The IntelliCenter Control System Web-Client where you utilize a PC, MAC or tablet to access your IntelliCenter through the web interface :grrrr: (More on that later).

3. The IntelliCenter iOS app which can be accessed through the applicable iPhone, iPad, iPad Touch device or Apple Watch.

4. The IntelliCenter Android app through the applicable android device.

5. IntelliCenter accessibility can also be accessed (for the most common pool/spa control commands only) through the Alexa app available for free through Amazon, if you have one of the various Amazon Echo’s, Fire TV cube, etc.

6. The optional IntelliCenter Control System Wireless Controller or Indoor Control Panels.

To be fair here, I have only used the Outdoor Control Panel, iOS device/app and the Web-Client (PC) to access, control and configure IntelliCenter. I have also used Alexa/Echo to give some of the common commands to IntelliCenter. I cannot comment on the Android app, Apple Watch, or the Wireless or Indoor Control Panels, since I have not used those devices.

Below, I have attempted to provide my assessments on the use of the IntelliCenter Control System, based on my own personal experiences so far. Some of my opinions may change over time if I find certain “work-arounds” and/or (hopefully) software and firmware upgrades are applied that change various functionality, etc.

The Good: Here is what I really like about IntelliCenter so far.

1. Onboard Ethernet port. Using the onboard Ethernet Port for direct connectivity to my router worked out really great. Right after initial power on, It immediately went out and grabbed an available DHCP IP address from my router (I later changed it to a static address).

2. Recognition and integration of the additional capabilities (flow rate and pump speed) of the newer Pentair IntelliFlo VSF pump (011056) or the Pentair IntelliFloXF VSF pump (022056).

3. The Setup Wizard. I thought Pentair did a good job with this.

4. The Additional Feature Circuits and Circuit Groups (Macro Circuits) available. Not that I have come close to utilizing them all “yet”, (13 out of 32 Feature Circuits (not counting the 5 main Circuits that I show as “feature”) and (8 out of 16 Circuit Groups), but I can certainly see how I can come close, especially as I continue to find “new ways” to automate various functions and certainly when RS-485 support for the IntelliValve and possibly the IntellipH as well, become available in the future.

5. The touchscreen is pretty cool and I find it fairly easy to navigate with all in all, as far as touchscreens go.

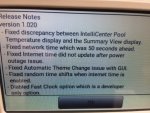

6. Automatic update “pushes”. I just received a firmware update a few days ago. Once an update is received, the next time you access the touch screen, it will advise you of this and ask you to ACCEPT the update and then it will list the update release notes. Here is an example below. (I will have to put this in another post, as I have reached the "10 images limit" I guess)

NOTE: This update alone, fixed two of my “beefs” that I was going to place on my "punch" list, so hopefully there will more updates soon and I will have no further “beefs”.

NOTE: You can always access ALL of the release notes from the previous updates, from the control panel touchscreen at any time.

The Bad: Certainly the IntelliCenter is not the panacea for every pool issue or configuration (no automation system is), but here are a couple of things that I believe Pentair could do a better job with, as it relates to the IntelliCenter automation.

1. TouchScreen readability in the sun. As predicted in another earlier thread, the Capacitive Touch Screen is a bit hard to see in the bright Arizona sunlight. I turned up the brightness to 100 but there is no contrast control to adjust. It’s not super-bad and you can shield with one hand which helps a bit, but it is still a little annoying when the sun is shining bright, especially if you're wearing “shades" On the other hand, it rocks on a cloudy day or at night! If your Load/Power Center is “under cover” or shielded from the sun in any way (shade sail, etc.), this will not be an issue.

2. Water and Air Temperature Sensor Calibration. I am placing this particular issue in the “bad” column and not “ugly” (although it’s driving me nuts), due to the fact that I am of the understanding that this may not be an IntelliCenter issue but instead, may be due to sensor or user malfunctions. I have insulated the Water Sensor from the sun and the Air Sensor is mounted in the normal location at the bottom of the Load Center, so it is also shielded from the sun. Every time I adjust the calibrated value, it does not take long for both values to get “out-of-wack”. Like right now, on a December evening (actual Air Temp is 54), IntelliCenter is reporting the Air Temp “True Readout” at 77 and Water Temp True Readout” at 74 (no way). I have been chasing these two values for weeks now and cannot get them to “settle-in”. Again, I don’t know if this is an IntelliCenter issue, a “two bad sensors” issue or a “user” malfunction (likely I may have to address this issue in a separate thread in order to attempt to resolve it.

UPDATE: (3/8/19) I think this issue has been improved by adding the 0.1uF Microfarad capacitors as discussed in thread #30. I don't think this was an IntelliCenter issue now. I just think the sensors are just not that accurate!

1. IntelliCenter Control System Web-Client. This has to be numero uno for me!!! I would consider myself fairly “IT” savvy and I have worked with a lot of various web and touchscreen applications over the years, so I am no “rookie” in these matters. Okay, I’m trying to be nice here, but who wrote the code for this web application and why hasn’t Pentair done a better job at making it do what it is supposed to do, correctly, the first time out. I've listed some examples below. (Just to note, upon discovering these deficiencies, I attempted to use other major web browsers, just to be sure it wasn’t just a Firefox compatibility issue).

2. Currently, as far as I can ascertain, if you setup a FEATURES GROUP, that involves the pump (as least the VSF for sure), all the FEATURES listed in the FEATURES GROUP will activate (as indicated by the applicable icons), but the pump (motor) will not actually spin, WHEN EMBEDDED AND ACTIVATED FROM A SCHEDULE. The pump has power and there are indications on the control panel, that it is ON, but the motor will not be running. I have devised a work-around for this "bug", by utilizing (scheduling) multiple individual FEATURES in the scheduling page. Pentair is looking into this “glitch”

UPDATE: This issue was corrected by Pentair.

3. Local Access. The ability to access my IntelliCenter Control Panel “locally” when using the Web-Client I have attempted to access my IntelliCenter Control panel locally utilizing both its IP address and using a program that will utilize its mac address from my desktop. I have tried both http: and https: At this time, this capability is a big fat NO GO!

Maybe, there is a work-around but I have yet to find it. And I can access just about every other device I own, that utilizes user-defined configurations, locally (by IP address). And get this. All the while, I CAN access my IntelliCenter control panel locally through the iOS app, (which uses the IP address assigned to the IntelliCenter Control Panel) ??? The iOS app will actually give you the option of accessing it locally or though the Pentair portal. REALLY? Keep in mind that this “local access” capability only exists from the iOS app if you are connected through your local network (WiFi) or if you are utilizing a VPN capability outside of your local network. Pentair, I really think you can do better. Maybe hire an Apple Web Consultant and let them show you how it’s done. C’mon Man!

4. IntelliCenter Web-Client User’s Guide. This user’s guide is very lacking and does not answer many questions, it is not very specific and does not contain enough detail to be useful. It appears that it was just “thrown” together without much forethought or planning. Looks as if it was not written by an experienced Technical Writer.

I have attempted to comply with the TFP Guidelines for Posting Reviews, while drafting this particular review and I am not promoting nor am I advising against, the use of the Pentair IntelliCenter Control System, or any other automation system for that matter. I have attempted to be fair and honest in my assessments of this particular automation system, based upon my own personal experiences up to this point.

I will update this thread as time goes on, as I work with Pentair on some “bug” issues and if I discover new and relevant information regarding the installation and use of the Pentair IntelliCenter Control System.

Background:

Earlier in the year, I had decided to completely renovate and update my pool equipment pad. I spent many hours on the computer (especially here on TFP) doing lots of research on advanced plumbing techniques, equipment specifications, automation integration, etc.

IntelliCenter still had not been released at the time I decided to get started (July). After some online research and contacting one of the local Pentair reps, it was determined that if I installed a Pentair IntelliTouch/EasyTouch Load Center, that I could then convert it to IntelliCenter later, once the newer automation system was released. Great! I could at least get a head start and get the electrical laid in, and then I could decide later on whether to go with the IntelliCenter Control System or one of the other Pentair automation systems.

So I ordered ONLY the IntelliTouch/EasyTouch Load Center at that time and started digging. I retrenched (ouch - 18” deep) from the equipment pad location about 120 feet to the house electrical service entrance. I laid in new 60 amp service to the new Pentair Load Center (good thing my neighbor is a commercial electrical contractor). He gave me all the advice I needed and then helped me with the “pull” through the conduit). But he sure didn't help me dig

I was now ready for the automation. I had been advised by some, to maybe think twice about the IntelliCenter and possibly consider opting with the tried and true ScreenLogic type systems (IntelliTouch or EasyTouch), since the IntelliCenter was still so new and not much was known about it at that time. This advice was certainly sound, based on information available at the time and based on their past experiences, but after some exhaustive research and willing to "jump-in" and take a chance, I was determined to move ahead with the IntelliCenter integration anyway.

My decision towards IntelliCenter versus the ScreenLogic type automation systems was based on many factors, some of which I have outlined below, others that I have chosen to keep to myself due to the fact that I respect everyone’s decision to choose their own type of automation system based on their own personal preferences and their particular needs and requirements.

1. Newer technology and the capacity for further enhancements in the future.

2. Web Based (no need for configurator type utilities and programs).

3. Since I greatly prefer wired connectivity (when available) versus wireless (for a myriad of reasons), I could “lay-in” Cat5E to the equipment pad and just “plug and play”, due to the onboard ethernet port (built-in connectivity) located on the IntelliCenter Control System Main Circuit Board. (I ran a 1” conduit using grey electrical pvc, from the side of the house (attic) to a low voltage raceway “knockout” and pulled in the Cat-5E).

4. Automatic software and firmware update “pushes” versus the “flash-upgrade” style updates that I understand requires an expensive Pentair Automation Flash Programming Kit.

5. Future expandability, flexibility and upgradeability (i.e. future RS-485 support for IntelliValve and possibly IntellipH as well).

6. USB port which allows for saving the latest system configuration file. (i.e. If experimenting with a new System Configuration, Schedules, Features, Feature Groups (macros), etc. and I goof something up, I can always revert back to the last saved config file and start over).

7. No real cost difference from other similar systems due to several factors that I will not elaborate on here.

8. Built-in integration support for the new Pentair IntelliFlo VSF pump (011056) (which I had opted for and installed) or the Pentair IntelliFloXF VSF pump (022056).

9. Built-in integration support for the new Pentair IntelliValve (two come bundled with the personality kits).

10. Larger Capacitive type screen which is touch sensitive, and which would allow me better access to ALL functionality at the equipment pad (when preferred or required).

11. 32 “Feature Circuits” capability.

12. 16 “Feature Groups” (“macros”) capability.

13. A whopping 100 available "Schedules".

I was told by Pentair Tech Support and authorized Pentair dealers that were offering the IntelliCenter, that I would need the Pentair IntelliCenter upgrade/retrofit kit, and that it would not be released until the March 2019 time frame. But I forged ahead anyway and continued conducting my own research on IntelliCenter, in order learn as much as I could about the newer automation system.

I contacted the local Pentair rep again. After some research on their part, I was told that I DID NOT in fact, have to wait for the upgrade kit. I was told that what I needed was just the i5PS personality kit (521912), the IntelliCenter System Transformer kit (522102Z) and because I was going to incorporate six valve actuators with the automation (the personality kit will only allow for four), that I needed the Valve Expansion module (522038Z) (I already knew about this one). All of this made sense to me but I was a little nervous about the whole affair, since it appeared that I was now being the “guinea pig” with all of this, since it was so “new”

Okay, so I took a deep breath, grabbed the VISA card and called PolyTec pools and proceeded to place my order. By this time, I had decided on the IntellipH versus the IntelliChem, due to my research and the good and sound advice I believe, that I received from other members here on TFP. So I also ordered that (the ipH) as well, along with four additional Pentair IntelliValves. (again, the personality kit includes two IntelliValves).

Converting the IntelliTouch/EasyTouch Load or Power Center for IntelliCenter: (The following is NOT applicable for those future IntelliCenter users that do not already have an IntelliTouch or EasyTouch Load/Power Center that they are converting to IntelliCenter!

The first thing I needed to do was to convert my IntelliTouch Load Center to accept the IntelliCenter. That meant the removal and replacement (r&r) of the system transformer and some of the low voltage circuit breakers.

The only difference that I can tell between the IntelliTouch/EasyTouch system transformer and the new IntelliCenter system transformer is that the low voltage circuit breaker wiring harness is different (the voltage and amperage specifications are the same as far as I can tell), however it does look different and feels heavier.

Note: When purchasing the IntelliCenter System Transformer kit (522102Z), the kit will include the transformer, mounting hardware and the two new 18V-5A and 24V-4A low voltage circuit breakers that are required to replace the older low voltage circuit breakers.

The IntelliTouch/EasyTouch Load/Power Centers utilize three (3), 3-amp system low voltage circuit breakers (along with the optional grey SWCG 24Vac, 12A breaker). These are for the following:

Electronics: 12V, 3A

Valves: 24V, 3A

Relays: 18V, 3A

The IntelliCenter utilizes only two (2) low voltage circuit breakers (also along with the optional grey SWCG 24Vac, 12A breaker).

These are for the following:

Electronics: 18V, 5A

Valves 24V, 4A

Relays: NONE (different type of circuitry I assume)

Removing and replacing the system transformer and the low voltage circuit breakers, was not too bad of a chore but it was a bit time consuming, as I was taking my time with it, so as to not “break” anything, and since no instructions were included in the kit.

WARNING: You should always remove power from the Load/Power Center at the main circuit breaker panel/service entrance circuit breaker that feeds power to the Load/Power Center, before removing the high voltage cover panel (dead front). If you are not completely comfortable or confident in your abilities to do this type of work, I highly suggest that you consult with and hire a licensed and experienced professional who is.

1. Once you have removed power from the Load Center/Power Center, remove the Load/Power Center high voltage cover panel (dead front). Can you figure out why it’s nicknamed a “dead front”?

2. Disconnect the appropriate line power leads from the system transformer to the breaker.

3. Unplug the connector that is connected to the older system board that is attached to the system transformer (I did not have to do this, since I only had the load center and no other system board yet) and unplug the connectors at the back of the low voltage circuit breakers (insure that you note what color of wires you are unplugging from which circuit breakers so you know what goes where, when you replace these connections with the newer circuit breakers).

4. Remove the four transformer mounting screws and remove the system transformer.

5. You will then have to completely remove the low voltage circuit breaker housing mount (a bit of a pain but do-able).

6. Remove the three (3) old low voltage circuit breakers from the mount and replace with the two (2) new low voltage circuit breakers in the low voltage circuit breaker housing mount.

7. Install the new IntelliCenter System Transformer in the Load/Power Center.

8. Install the low voltage circuit breaker housing mount in the Load/Power Center.

9. Re-connect the appropriate line power leads from the system transformer to the applicable circuit breaker (120Vac or 240Vac).

10. Replace the Load/Power Center high voltage cover panel (dead front).

11. Return power back to the Load/Power Center at the main service entrance HOWEVER, ensure that the breaker that supplies power to the system transformer is in the OFF position for the moment before proceeding.

You are now ready to mount the IntelliCenter System Board in the Load Center. However, in my case, I had to attach the optional Valve Expansion module (522038Z) to the System Board first. It’s very easy, but a word of warning here. You are handling circuit boards which are very receptive to damage from static electricity. Ensure that you take the necessary precautions recommended to eliminate the possibility of static electricity damage to the circuit boards.

Attach the connector from the Control System Transformer cable to the Circuit board/Touch screen assembly.

Energize the circuit by placing the applicable circuit breaker back to the ON position.

Initial Power-up and Setup Wizard:

Once power is applied to the IntelliCenter Control System, the system will perform an initial power-up sequence and you will be presented with a Pentair End User License Agreement, which you have to scroll down through and then tap the I Accept button to proceed. This will occur only once, at the initial power-up.

I highly recommend that the Setup Wizard be utilized in order to get started. To start the Setup Wizard from the home screen, tap Settings > Advanced System Configuration > Wizard. I found using the wizard easy and it basically walks you through all the steps in order to configure all of the basic setup items to include the Network and WiFi (if applicable) setups. You can skip items that you want to come back to later.

Once the network configurations are completed, all other General, Advanced System Configurations, Circuit, Feature Circuit, Circuit Groups, Chemistry Control, Other Equipment (Valves, Heaters & Covers), Pumps and Remote(s) (If applicable) configurations and settings can be completed using one of several user interfaces.

User Interfaces:

There are several user interfaces available to control and/or configure IntelliCenter.

1. The IntelliCenter Control System Outdoor Control Panel (obviously).

2. The IntelliCenter Control System Web-Client where you utilize a PC, MAC or tablet to access your IntelliCenter through the web interface :grrrr: (More on that later).

3. The IntelliCenter iOS app which can be accessed through the applicable iPhone, iPad, iPad Touch device or Apple Watch.

4. The IntelliCenter Android app through the applicable android device.

5. IntelliCenter accessibility can also be accessed (for the most common pool/spa control commands only) through the Alexa app available for free through Amazon, if you have one of the various Amazon Echo’s, Fire TV cube, etc.

6. The optional IntelliCenter Control System Wireless Controller or Indoor Control Panels.

To be fair here, I have only used the Outdoor Control Panel, iOS device/app and the Web-Client (PC) to access, control and configure IntelliCenter. I have also used Alexa/Echo to give some of the common commands to IntelliCenter. I cannot comment on the Android app, Apple Watch, or the Wireless or Indoor Control Panels, since I have not used those devices.

Below, I have attempted to provide my assessments on the use of the IntelliCenter Control System, based on my own personal experiences so far. Some of my opinions may change over time if I find certain “work-arounds” and/or (hopefully) software and firmware upgrades are applied that change various functionality, etc.

The Good: Here is what I really like about IntelliCenter so far.

1. Onboard Ethernet port. Using the onboard Ethernet Port for direct connectivity to my router worked out really great. Right after initial power on, It immediately went out and grabbed an available DHCP IP address from my router (I later changed it to a static address).

2. Recognition and integration of the additional capabilities (flow rate and pump speed) of the newer Pentair IntelliFlo VSF pump (011056) or the Pentair IntelliFloXF VSF pump (022056).

3. The Setup Wizard. I thought Pentair did a good job with this.

4. The Additional Feature Circuits and Circuit Groups (Macro Circuits) available. Not that I have come close to utilizing them all “yet”, (13 out of 32 Feature Circuits (not counting the 5 main Circuits that I show as “feature”) and (8 out of 16 Circuit Groups), but I can certainly see how I can come close, especially as I continue to find “new ways” to automate various functions and certainly when RS-485 support for the IntelliValve and possibly the IntellipH as well, become available in the future.

5. The touchscreen is pretty cool and I find it fairly easy to navigate with all in all, as far as touchscreens go.

6. Automatic update “pushes”. I just received a firmware update a few days ago. Once an update is received, the next time you access the touch screen, it will advise you of this and ask you to ACCEPT the update and then it will list the update release notes. Here is an example below. (I will have to put this in another post, as I have reached the "10 images limit" I guess)

NOTE: This update alone, fixed two of my “beefs” that I was going to place on my "punch" list, so hopefully there will more updates soon and I will have no further “beefs”.

NOTE: You can always access ALL of the release notes from the previous updates, from the control panel touchscreen at any time.

The Bad: Certainly the IntelliCenter is not the panacea for every pool issue or configuration (no automation system is), but here are a couple of things that I believe Pentair could do a better job with, as it relates to the IntelliCenter automation.

1. TouchScreen readability in the sun. As predicted in another earlier thread, the Capacitive Touch Screen is a bit hard to see in the bright Arizona sunlight. I turned up the brightness to 100 but there is no contrast control to adjust. It’s not super-bad and you can shield with one hand which helps a bit, but it is still a little annoying when the sun is shining bright, especially if you're wearing “shades" On the other hand, it rocks on a cloudy day or at night! If your Load/Power Center is “under cover” or shielded from the sun in any way (shade sail, etc.), this will not be an issue.

UPDATE: (3/8/19) I think this issue has been improved by adding the 0.1uF Microfarad capacitors as discussed in thread #30. I don't think this was an IntelliCenter issue now. I just think the sensors are just not that accurate!

1. IntelliCenter Control System Web-Client. This has to be numero uno for me!!! I would consider myself fairly “IT” savvy and I have worked with a lot of various web and touchscreen applications over the years, so I am no “rookie” in these matters. Okay, I’m trying to be nice here, but who wrote the code for this web application and why hasn’t Pentair done a better job at making it do what it is supposed to do, correctly, the first time out. I've listed some examples below. (Just to note, upon discovering these deficiencies, I attempted to use other major web browsers, just to be sure it wasn’t just a Firefox compatibility issue).

a) Saving. Just about every time I attempt to create or modify a Feature Circuit, Circuit Group (macro) or sometimes a schedule and click SAVE, in the Web-Client, it does not always “take” the first time. I have to then redo it. If I do not give it enough time to “take”, then it will create a duplicate on the second go-around and it seems to get “confused”. Many times, you have to exit the SYSTEM CONFIGURATION page first by clicking on the HOME button and then navigate back to the SYSTEM CONFIGURATION page to see what happened. What? C’mon Man!

b) Character Length Limitations. The Web-Client has some really short character limitations when creating Feature Circuit Names, Circuit Group Names and Valve Names. Sometimes, so much so, that you (the one that is actually creating the names) have to think about what that Feature Circuit, Circuit Group Name and Valve name is really for! Really? There is probably a reason for this but I would vote, probably not a very good one and probably just not a lot of effort given to writing the code. C’mon Man!

c) Sorting. Are you telling me that a web designer did not consider the fact that a user just might want to sort things like Aux Circuits, Feature Circuits, Circuit Groups, Pumps, Circuits listed on the Pump Page, Lights, etc. to their own liking? Like maybe alphabetically, or by common use, or by time-of-day, or by any other criteria the user might want to define. C’mon Man!

d) Schedule Time Configurations. Schedules have to be at the half hour ONLY when creating or modifying schedules in both the Web-Client and the iOS app. It will let you type in something else (such as 10:15), but when you click SAVE, the scheduled time always defaults to the closest half hour. Also, if you want to have a schedule that goes past midnight, it cannot be a continuation of a particular schedule (i.e. 11:00pm to 2:00 am). You have to create two schedules (i.e. 11:00pm to 12:00pm and then 12:00am to 2:00 am). HOWEVER, YOU CAN set schedules that are NOT restricted to the half hour, when programming from the Control Panel. ??? C’mon Man!

e) No “FEATURES GROUPS” on the “HOME” or “FEATURES” tab. When you click the HOME tab or the FEATURES tab from the HOME PAGE, it only lists the individual FEATURES and not the FEATURES GROUPS (macros). Hence, you cannot activate a FEATURES GROUP from the web application. NO, instead you have to click each and every individual FEATURE that you want activated “separately” if you want to activate them from the Web Application. HOWEVER, if you go to the FEATURES tab in the iOS app or use the Outdoor Control Panel, you CAN select or activate a FEATURES GROUP from the FEATURES tab. Yikes!! C’mon Man!

UPDATE: (3/8/19) This issue has been corrected in Web Client Version 1.023b4

UPDATE: This issue was corrected by Pentair.

3. Local Access. The ability to access my IntelliCenter Control Panel “locally” when using the Web-Client I have attempted to access my IntelliCenter Control panel locally utilizing both its IP address and using a program that will utilize its mac address from my desktop. I have tried both http: and https: At this time, this capability is a big fat NO GO!

Maybe, there is a work-around but I have yet to find it. And I can access just about every other device I own, that utilizes user-defined configurations, locally (by IP address). And get this. All the while, I CAN access my IntelliCenter control panel locally through the iOS app, (which uses the IP address assigned to the IntelliCenter Control Panel) ??? The iOS app will actually give you the option of accessing it locally or though the Pentair portal. REALLY? Keep in mind that this “local access” capability only exists from the iOS app if you are connected through your local network (WiFi) or if you are utilizing a VPN capability outside of your local network. Pentair, I really think you can do better. Maybe hire an Apple Web Consultant and let them show you how it’s done. C’mon Man!

4. IntelliCenter Web-Client User’s Guide. This user’s guide is very lacking and does not answer many questions, it is not very specific and does not contain enough detail to be useful. It appears that it was just “thrown” together without much forethought or planning. Looks as if it was not written by an experienced Technical Writer.

Last edited: