Yes, it's Easytouch, I want to say Easytouch8 but would need to check. I have a basic RF remote, but not an indoor control pad and don't use the app preferring the outside control panel.You may find you will want to remove the trichlor feeder, and use that distance to add before the IC. Especially if the infloor cleaner needs higher rpm to operate.

Yes, the overall Pentair system. Likely Easytouch. Do you have an app or remote to operate the system?

Pentair IC60 Flow Switch keeps going bad

- Thread starter BWC

- Start date

-

- Tags

- flow switch ic60 interllichlor swg

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BWC,

The flow switch is definitely a safety device, but maybe just not the type of safety device you are used to seeing.

The IC40 has two safety "features".. The Primary safety feature is that the cell does not get any power when the pump is not running. In your case this is because your automation does not send any power to the cell if the main pump is not being told to run. (Sounds like this is working as it should)

The Secondary safety features is the flow switch, if there is no water flowing through the cell the flow switch shuts the cell off so that it can't make chlorine.

As long as the Primary safety feature is working, then it does not matter if the flow switch is working. But here is the issue. It is very possible for the automation to tell the pump to run, but that the pump fails to run. In this case the cell would get power without any water flow.

It is your pool, and you can run it anyway you want, but I would never recommend shorting the flow switch other than for a quick test.

I agree with Marty, running your main pump at 3450 RPM is just crazy!!!

I too would remove the tab feeder and move the cell so that it has at least a foot of straight pipe after the 90..

Thanks,

Jim R.

The flow switch is definitely a safety device, but maybe just not the type of safety device you are used to seeing.

The IC40 has two safety "features".. The Primary safety feature is that the cell does not get any power when the pump is not running. In your case this is because your automation does not send any power to the cell if the main pump is not being told to run. (Sounds like this is working as it should)

The Secondary safety features is the flow switch, if there is no water flowing through the cell the flow switch shuts the cell off so that it can't make chlorine.

As long as the Primary safety feature is working, then it does not matter if the flow switch is working. But here is the issue. It is very possible for the automation to tell the pump to run, but that the pump fails to run. In this case the cell would get power without any water flow.

It is your pool, and you can run it anyway you want, but I would never recommend shorting the flow switch other than for a quick test.

I agree with Marty, running your main pump at 3450 RPM is just crazy!!!

I too would remove the tab feeder and move the cell so that it has at least a foot of straight pipe after the 90..

Thanks,

Jim R.

Good thought about removing the feeder to allow more room. Yes, it's an Easytouch, I want to say Easytouch8 but need to confirm. I have a basic RF remote, but not the indoor remote panel nor use the app, preferring to use the outdoor control panel.You may find you will want to remove the trichlor feeder, and use that distance to add before the IC. Especially if the infloor cleaner needs higher rpm to operate.

Yes, the overall Pentair system. Likely Easytouch. Do you have an app or remote to operate the system?

BWC,

If you have ScreenLogic, then programming is dirt simple.

I use my PC for programming as it works much better than the phone.

Thanks,

Jim R.

If you have ScreenLogic, then programming is dirt simple.

I use my PC for programming as it works much better than the phone.

Thanks,

Jim R.

Agree that it may act as a safety device, but can't find in any of the docs I have where it's described as such. As stated earlier in the thread, the main pool pump was programmed at that speed when I bought the house. I don't know complete history but do know it was professionally maintained for at least 3 years before I bought so I'm assuming they had their reason. That said, unless the infloor cleaning system requires it to run at that speed, I wholeheartedly agree that 3450rpm is too high and posed the high flow rate as a possibility of switch failure in my initial post. Agree that removing the feeder and extending the run before the IC40 to 12"+ can only help and would seem to likely fix my problem.BWC,

The flow switch is definitely a safety device, but maybe just not the type of safety device you are used to seeing.

The IC40 has two safety "features".. The Primary safety feature is that the cell does not get any power when the pump is not running. In your case this is because your automation does not send any power to the cell if the main pump is not being told to run. (Sounds like this is working as it should)

The Secondary safety features is the flow switch, if there is no water flowing through the cell the flow switch shuts the cell off so that it can't make chlorine.

As long as the Primary safety feature is working, then it does not matter if the flow switch is working. But here is the issue. It is very possible for the automation to tell the pump to run, but that the pump fails to run. In this case the cell would get power without any water flow.

It is your pool, and you can run it anyway you want, but I would never recommend shorting the flow switch other than for a quick test.

I agree with Marty, running your main pump at 3450 RPM is just crazy!!!

I too would remove the tab feeder and move the cell so that it has at least a foot of straight pipe after the 90..

Thanks,

Jim R.

At full speed, the flow coming out of the 90 is very turbulent and it will cause the metal part to flutter.

You are definitely running the pumps way too fast.

At full speed, they use more than 3,000 watts.

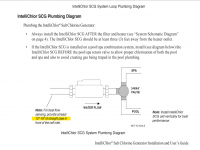

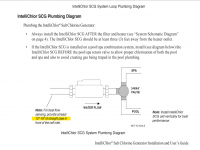

The cell should have 12" to 18" of straight pipe before the cell.

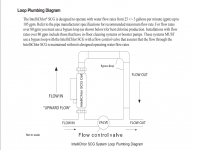

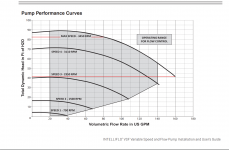

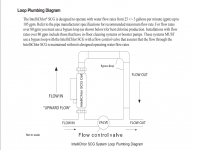

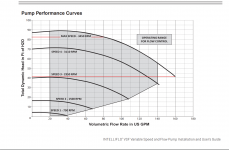

At flow over 80 GPM, the manual indicates the need for a bypass loop.

At full speed, the pump easily goes over 80 GPM and it can get to 160 GPM, which is twice the limit.

Also, NEVER bypass the flow switch.

If the cell generates hydrogen and chlorine gas with no flow, the cell and PVC pipe become a pipe bomb that can explode.

You are definitely running the pumps way too fast.

At full speed, they use more than 3,000 watts.

The cell should have 12" to 18" of straight pipe before the cell.

At flow over 80 GPM, the manual indicates the need for a bypass loop.

At full speed, the pump easily goes over 80 GPM and it can get to 160 GPM, which is twice the limit.

Also, NEVER bypass the flow switch.

If the cell generates hydrogen and chlorine gas with no flow, the cell and PVC pipe become a pipe bomb that can explode.

Thanks much for the diagrams and info!! There's definitely not a bypass in my system. In attempting to resolve the problem, I'll begin by removing the feed tube and extend the IC out further from the elbow. My calibrated eyeballs tell me that I should end up with about a 14" run into the switch. I'll then need to experiment with the speed setting to judge the impact of a lower speed on the infloor cleaning. 3450rpm may or may not be warranted.

Thanks to all for your help and sage advice!

Thanks to all for your help and sage advice!

What model is the in-floor system?

Is there a pressure gauge on the in-floor valve?

Is there a pressure gauge on the in-floor valve?

What model is the in-floor system?

Is there a pressure gauge on the in-floor valve?

Apologize for not responding sooner as I have no documentation on the in-floor system and had to research it. It's a Paramount Pool & Spa PV3 Automatic Pool Cleaning System. The Water Valve has provision for a pressure gauge as pictured on their website but mine has the gauge bung plugged. I'd guess it broke off in the distant past and a plug was readily available. It should be easy enough to find a gauge that will fit.What model is the in-floor system?

Is there a pressure gauge on the in-floor valve?

I swapped out the one from the pool filter into the Water Valve so I can see what pressure it's operating at until a new valve arrives tomorrow.Apologize for not responding sooner as I have no documentation on the in-floor system and had to research it. It's a Paramount Pool & Spa PV3 Automatic Pool Cleaning System. The Water Valve has provision for a pressure gauge as pictured on their website but mine has the gauge bung plugged. I'd guess it broke off in the distant past and a plug was readily available. It should be easy enough to find a gauge that will fit.

Thanks once again. I'll run it and check the pressure later in the day. It's 10:15am, already 105 and climbing fast......

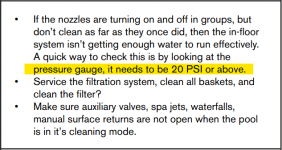

I braved the elements and got the in-floor system running using the pool filter's gauge. It's barely reading 5psi running at 3450rpm which explains why the grouped heads are not rotating as I was thinking they should. I'll follow the steps as far as cleaning out all the leaves and such in the hope of removing anything that maybe preventing it from obtaining at least 20psi. If it makes 20 or more psi then I'll figure out how to dial down the rpm.Thanks once again. I'll run it and check the pressure later in the day. It's 10:15am, already 105 and climbing fast......

- May 3, 2014

- 62,672

- Pool Size

- 6000

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

What was the gauge reading while it was on the filter?using the pool filter's gauge

First thing to check is the baskets and skimmers, I cleaned the filters 6-7 weeks ago but no harm in cleaning again.....Filter dirty?

It was reading just shy of 20 where it's been since I last cleaned it....What was the gauge reading while it was on the filter?

Pentair Intelliflo VSF, I don't see a specific model number anywhere on the pump. The indicated pressure on the pool filter gauge is somewhat lower than it was before cleaning the filters, ~ 30 before and 20 after on a 0 - 60 scaled gauge.Seems low for an Intelliflo at 3,450 RPM.

What is the pump model number?

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.