- Mar 8, 2024

- 51

- Pool Size

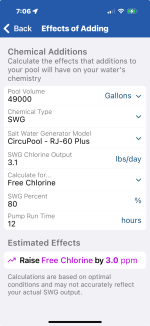

- 49000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

Hi hope all is well! I'm looking to convert over from buying bulk liquid chlorine to SWG. Based on online calculators, I'm estimating my pool to be approximately 49k gallons (20'x50', 3.5' shallow end, 9.5' deep end).

I was considering doing this myself and am interested in the CircuPool generators. I'm deciding between the RJ60+ vs Core55.

Based on what I've read, I should purchase a SWG whose capacity is double the size of my pool. If that's the case, would you recommend I purchase 2 cells and run them in parallel? Thanks in advance!

I was considering doing this myself and am interested in the CircuPool generators. I'm deciding between the RJ60+ vs Core55.

Based on what I've read, I should purchase a SWG whose capacity is double the size of my pool. If that's the case, would you recommend I purchase 2 cells and run them in parallel? Thanks in advance!