tf,

Not sure where to start...

Filter wise, it does not really matter.. Since you already have a drain pipe (to the sewer I hope), then I would leave it DE.. You can go cartridge if you wish, but maintenance wise they are both about the same amount of work..

Robot wise, I would go with a Dolphin.. I suggest you use the search function in the upper right of the screen and look at the 1/4 million posts on robots...

Your Jandy Truclear11K Salt Water Generator is basically worthless (sorry) but it is rated for an 11K pool and that is when it is running 24 hours a day at 100%.. We always recommend using a cell that is rated for at least 2 x your water volume.. You need a 40K cell... and the electronics that goes with it.

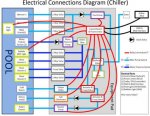

Actuator wise... Your diagram only shows needing two.. But, one of those two is for a pressure side cleaner driven by a booster pump. I did not notice this before, but you would not normally use a valve to control the water going to a booster pump. You would normally use an actuator controlled valve (on the suction side) if you were trying to control a suction side cleaner.. You do not need this valve or actuator at all... whether you keep the pressure side cleaner or not...

Check valve wise, you just don't need any of them. Well operating system hold their prime without any check valves. I have three pools and none of them have check valves. You would need a check valve to prevent a Chlorine Tab Dispenser from feeding back into a heater, but you don't have a heater or a tab dispenser, you have a SWCG. All the water throughout your whole plumbing will be saltwater, so how would a check valve prevent the movement of salt water????

I am a Pentair kind of guy and am not fan of Jandy automation systems, but that is more because I don't understand them very well.. They have too many mix and match options that just confuse things for me.. That said.. the most important thing about automation is to make sure that the Automation system, any VS pump, and any SWCG all are the same brand. This is the easiest way to make sure everything talks to each other.

From a generic automation system point of view, I think you need a unit that comes with a load center for all your circuit breakers, and a number of AC control relays.. Most systems have 4 or 8 relays.. you will need 8 relays because of all the things you want to control.

Your VS pump will be controlled by a small serial cable not a relay..

Your Single speed water feature pump will need a relay..

Your Pool light will need a relay..

Your Bubbler light will need a relay..

Your Chiller will need a relay..

Your Salt system will need a relay.. usually called the Pump/Filter relay which will shut off the power to the SWCG when the main pump is not running..

Your booster pump will need a relay (If you go with a pressure side cleaner)..

Your Landscape light will need a relay..

You will need a spare relay, because something always needs to be added later...

Your Actuator(s) do not use relays, they have special outputs from the main controller board. Most systems come standard with two (User programmable) valve circuits..

You will need to find a Jandy expert to answer your Jandy specific questions..

For comparison, here are the Pentair units that would do all the things you want to do..

Pentair Easy Touch Control System 520545. EasyTouch 8SC-IC40 Control System. Pentair 520545.

Pentair IntelliFlo Variable Speed Pump 011018 | Pentair 011018

Pentair ScreenLogic Interface and Wireless Connection Kit 522104 | Pentair 522104

Thanks,

Jim R.

Thanks in advance!

Thanks in advance!