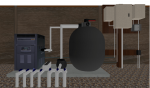

I will be installing a pool this spring, and I have looked over a ton of different setups. On paper I have put something together like this picture below.

3 - Input - 2"

4- output - 1-1/2"

All sweep 90's. My thought instead of using 2 90's going to the heater, there I would use to 45's since long sweep 90's is less head than using two 45's but going to the heater has 2 90's.

I also wanted to put values on each of the out put side.

Is there anything I should do different ?

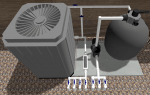

3 - Input - 2"

4- output - 1-1/2"

All sweep 90's. My thought instead of using 2 90's going to the heater, there I would use to 45's since long sweep 90's is less head than using two 45's but going to the heater has 2 90's.

I also wanted to put values on each of the out put side.

Is there anything I should do different ?