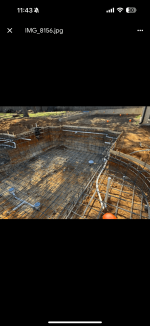

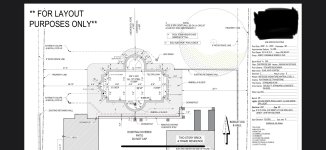

Hello. I am in the middle of a build and things seem to be moving along well. I have gained a ton of knowledge on this forum but am still new to this process. The pool co recently put down rebar and plumbing and things look ok to my eye. But someone pointed out to me that it’s a big problem that I have plumbing that will be embedded in the pool shell. Below is a picture. Any truth to this? What are the chances this creates a problem? Just trying to decide if I need to ask them to come back and fix things and if so exactly what I need to request.

Aside from that issue (assuming it is one) anything else you can identify? Pool is in DFW area if that matters.

Appreciate your insight.

Aside from that issue (assuming it is one) anything else you can identify? Pool is in DFW area if that matters.

Appreciate your insight.