I installed an IntellipH three months ago and have followed other threads by @Turbo1Ton and @Dirk showcasing their fixes for burned connectors. My connector looks fine but I don't want to be scrambling to fix it if it fails later. Plus, I think the fix is easier if the connector isn't burned.

I'm really good at snow skiing, mountain biking and copying what other people do. Otherwise I have no skills at anything else. To show you how poor my skills are, I need help understanding Fix #1 that @Dirk shared in his thread here

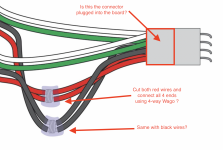

It appears you connect the two red wires (and also the two black wires) leading into the connector. Is that correct? If so, what does that actually do? I told you I'm not an electrician!

Also, if that is indeed what I need to do, can I just cut the two red wires and connect them with a 4-way Wago connector? I know the preferred connection is soldering but I rarely have good results soldering.

I'm really good at snow skiing, mountain biking and copying what other people do. Otherwise I have no skills at anything else. To show you how poor my skills are, I need help understanding Fix #1 that @Dirk shared in his thread here

It appears you connect the two red wires (and also the two black wires) leading into the connector. Is that correct? If so, what does that actually do? I told you I'm not an electrician!

Also, if that is indeed what I need to do, can I just cut the two red wires and connect them with a 4-way Wago connector? I know the preferred connection is soldering but I rarely have good results soldering.