It’s a process of elimination.

You have many different things that can be checked and verified.

As you work through the different checks, some will check out fine and some will have a problem.

When you have multiple issues, you need to find them and fix them.

The vacuum gauge is defective, so that should be replaced.

The flow meter might be inaccurate, so you can replace it or add a second flow meter to see if you get the same readings.

The impeller was “allegedly” “worn” and maybe it was and maybe it wasn’t.

The impeller replacement seems like it did not help much.

It’s usually best to fix the least expensive things first.

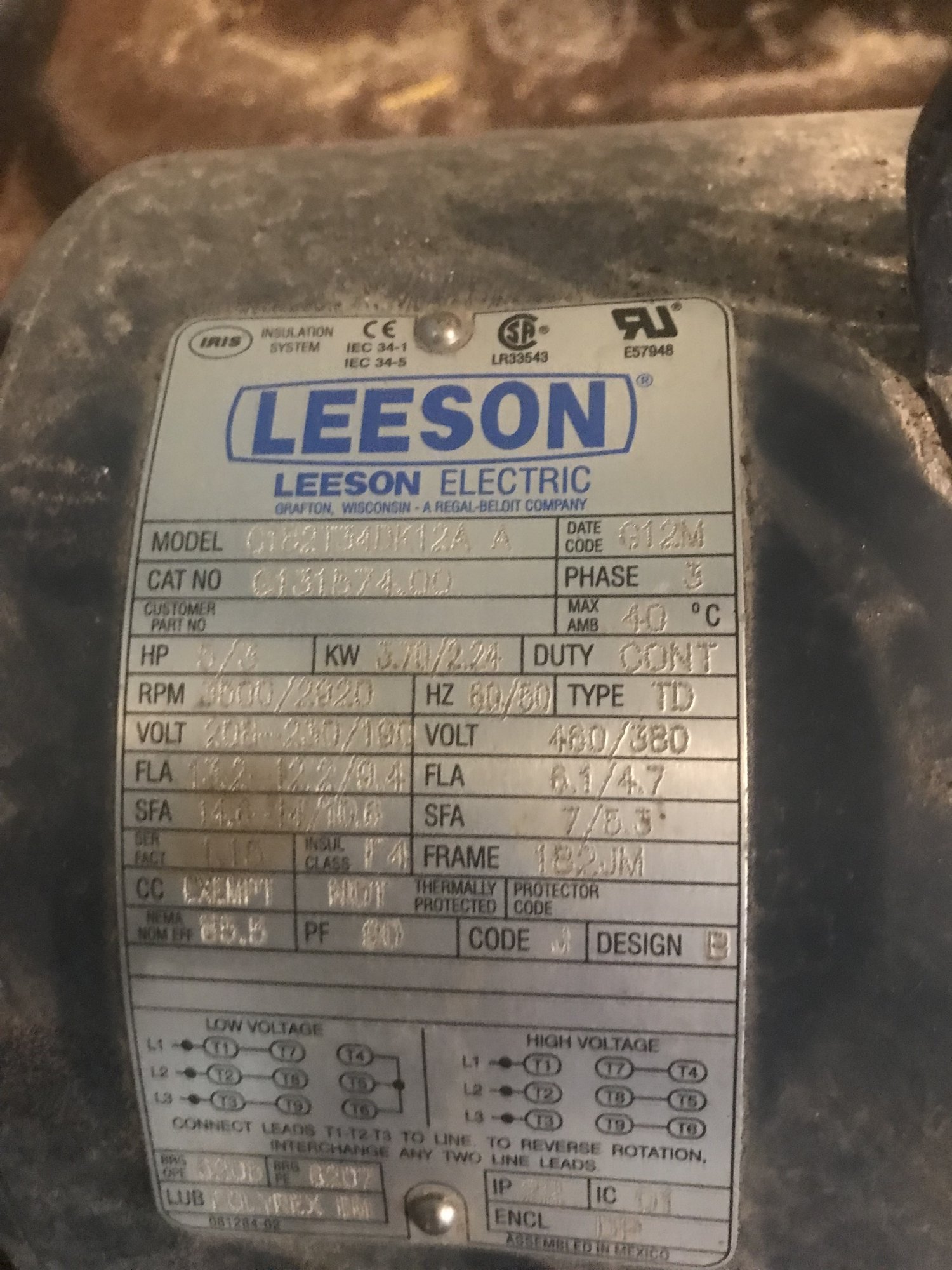

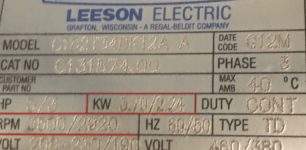

In my opinion, the motor sounds off, but that is difficult to tell for sure.

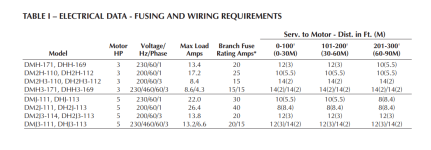

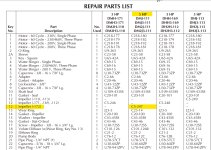

I would think that a Mechanical Contractor or an Electrician could do the necessary measurements in a standard service call.

Note that 99.9% of service people will not know how to check a 3-phase motor correctly.

So, you have to make sure that they know exactly what they are doing and that they give you a written evaluation including the actual measurements and an explanation of why the numbers are correct or not correct.

The low flow can under load the motor, so the current will be low.

Has this pump ever worked properly?

What is the highest recorded flow from the records?

You have many different things that can be checked and verified.

As you work through the different checks, some will check out fine and some will have a problem.

When you have multiple issues, you need to find them and fix them.

The vacuum gauge is defective, so that should be replaced.

The flow meter might be inaccurate, so you can replace it or add a second flow meter to see if you get the same readings.

The impeller was “allegedly” “worn” and maybe it was and maybe it wasn’t.

The impeller replacement seems like it did not help much.

It’s usually best to fix the least expensive things first.

In my opinion, the motor sounds off, but that is difficult to tell for sure.

I would think that a Mechanical Contractor or an Electrician could do the necessary measurements in a standard service call.

Note that 99.9% of service people will not know how to check a 3-phase motor correctly.

So, you have to make sure that they know exactly what they are doing and that they give you a written evaluation including the actual measurements and an explanation of why the numbers are correct or not correct.

The low flow can under load the motor, so the current will be low.

Has this pump ever worked properly?

What is the highest recorded flow from the records?