30 psi is about 69.3 feet of head.

The filter pressure should not go above about 16 psi at full flow, so there might be a problem with the sand or maybe something past the filter is causing a restriction.

Even accounting for the restriction, the flow is too low and you might have a problem with the suction or maybe a suction side air leak or maybe the pump is underperforming for some reason.

Make sure that the pump lid is sealing correctly as that is a common problem with metal lids.

Even a small air leak will cause the pump to underperform.

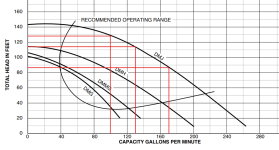

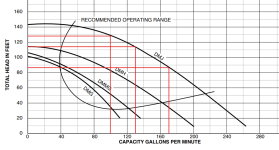

The flow is about 130 gpm, so that puts the total head at about 115 feet according to the pump performance curve.

115 (Total) - 69.3 (Return) = 45.7 feet (suction).

Suction cannot be more than about 17 feet before the pump will begin to underperform.

45.7 - 17 = 28.7.

34 feet is the maximum possible suction and the pump will begin to cavitate somewhere between about 17 feet and 34 feet.

So, the numbers do not add up.

The gauges might be incorrect or the pump might be underperforming.

Are you getting air into the system?

We need a vacuum pressure.

We need a second way to verify flow.

You should check the total power draw by the pump and check the voltage and current being supplied.

It is a 3 phase motor, so you need someone who knows how to work with 3 phase.

The motor specs are on the motor label.

If we allow up to 17 feet of head for the suction, then that is 86.3 feet total, which should be about 170 GPM.

115 feet (From pump curve at 130 gpm) - 86.3 feet (Estimated) = 28.7 feet unaccounted for.

The TR-140 is rated at 106 GPM (7.06 x 15 gpm/sqft).

2 = 212 GPM.

At 106 GPM, the head loss is about 12 feet from the filter, which is about 5.2 psi.

At 106 GPM, the head loss from the multiport is about 6 psi.

That is 11.2 psi from the filter and valve at 212 GPM total system flow.

30 - 11.2 = 18.8 psi (43.4 feet) for the return line past the filter, which is too high.

If we allow 4.6 feet for the return past the filter, then that is 38.8 feet too much.