Here is the section the technician is referring to. The "T" connects pipe coming out of both filters. At the first 90, there is about 28" of 1" pipe. At the second 90, there is about 12" of 1" pipe.Are you saying that the entire flow is being put through a 1" PVC pipe?

If yes, then this needs to be fixed as that is way too small for the flow.

I really do not think that that is something that anyone would do.

Are you sure?

How long is the 1" pipe?

Filter capacity?

- Thread starter JPMorgan

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

We have a new Treasurer who seems diligent about tracking expenses, so I'm pretty sure she can help with this.Request a copy of the places monthly electrical bill. That will show you the cost/kwh and all other surcharges per kwh.

Maybe this is wrong. Could it be 2" pipe that the technician is saying should be 3" pipe. Sorry if I mis-spoke.I really doubt that anyone would try to put 170 GPM through a 1" PVC pipe.

Do these prices seem high also? Contract says they do these things between September and March unless notified otherwise.If the $500 cost to clean each heater is in addition to the service contract cost it is laughable. Most HVAC clean and check costs are normally between $100-120 with many companies offering a clean and check at $70-80 to get their foot in the door. The manufacturer's recommendation of annual cleaning is more of a liability issue and may only be needed when a heater is installed in a location where it gets dirty very quickly or is highly attractive to spiders. Although an annual clean and check can catch some small problems before they become a larger problem.

- Test and Calibrate VGB Anti-Entrapment Device (To be done at opening) $ 100.00 per device

- Re-Condition Chemicals Feeders (Will be picked up during closing) $ 100.00 + materials

- Clean DE & Cartridge Filters: Association Has __2____ $ 200.00 each (we actually on have 1 DE filter)

- Clean Pool Heater (per manufacturer’s recommendations) $ 500.00 for 125 – 405BTU

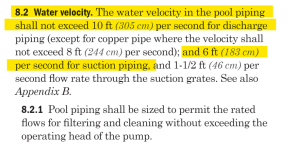

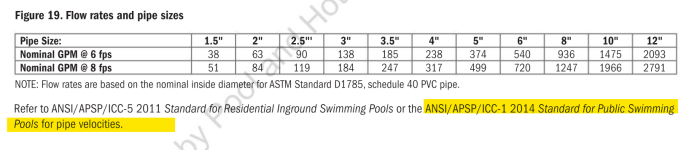

If the pipes are 2", then they can carry up to 84 GPM each for a total of 168 GPM.The regulations usually require that the velocity for suction remain below 6 feet per second and below 8 feet per second for the returns.

I really doubt that anyone would try to put 170 GPM through a 1" PVC pipe.

You want to keep the water velocity below 6 ft/sec on the suction and below 8 ft/sec on the pressure side of the pump.

Pipe Size 6 ft/sec 8 ft/sec 1.5" 38 GPM 51 GPM 2" 63 GPM 84 GPM 2.5 90 GPM 119 GPM 3.0" 138 GPM 184 GPM 4.0" 235 GPM 312 GPM

You cannot have a velocity in any suction pipe higher than 6 feet per second and you cannot have a velocity higher than 8 feet per second in any return line.

If the velocity is excessive, it needs to be fixed.

thephta Publisher Publications - Issuu

The Pool & Hot Tub Alliance advances the common interests of the industry by providing education, industry leadership, legislative and regulatory advocacy, standards development, research and market growth to increase our members' professionalism, knowledge and profitability.

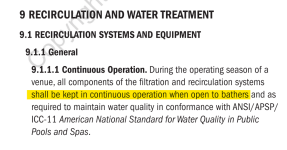

ANSI/APSP/ICC-1 2014 American National Standard for Public Swimming Pools

ANSI/APSP/ICC-1 2014 (R2023) American National Standard for Public Swimming Pools

This Standard provides recommended minimum guidelines for the design, equipment, operation, and installation of new construction and renovation of public pools for builders, installers, and pool operators. It also is intended to assist government and other regulatory bodies in the development...

2022 CPO Manual

Read 2022 CPO Manual by thePHTA on Issuu and browse thousands of other publications on our platform. Start here!

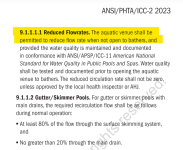

ANSI/PHTA/ICC-2 2023 American National Standard for Public Pool and Spa Operations and Maintenance

ANSI/PHTA/ICC-2 2023 American National Standard for Public Pool and Spa Operations and Maintenance provides public health officials, industry professionals, and code officials an easily adoptable set of guidelines for the operation and maintenance of all types of public aquatic venues. The...

ANSI/PHTA/ICC-2 2023 American National Standard for Public Pool and Spa Operations and Maintenance

ANSI/PHTA/ICC-7 2020 American National Standard for Suction Entrapment Avoidance in Swimming Pools..

The purpose of this standard is to establish anti-entrapment performance requirements for public and residential swimming pools, wading pools, field-constructed spas and hot tubs, and any other bather-accessible body of water, including but not limited to, catch pools, infinity edge basins, and...

ANSI/PHTA/ICC-7 2020 American National Standard for Suction Entrapment Avoidance in Swimming Pools..

ANSI/APSP/ICC-11 2019 American National Standard for Water Quality in Public Pools and Spas

The ANSI/APSP/ICC-11 2019 American National Standard for Water Quality in Public Pools and Spas provides recommended minimum guidelines for the specifications for recreational water quality parameters in public pools and spas. An Appendix A includes explanatory sections about the values for the...

ANSI/APSP/ICC-11 2019 American National Standard for Water Quality in Public Pools and Spas

TITLE 77: PUBLIC HEALTH

CHAPTER I: DEPARTMENT OF PUBLIC HEALTH

SUBCHAPTER n: RECREATIONAL FACILITIES

PART 820 SWIMMING FACILITY CODE

SECTION 820.210 SWIMMING FACILITY WATER TREATMENT SYSTEM

CHAPTER I: DEPARTMENT OF PUBLIC HEALTH

SUBCHAPTER n: RECREATIONAL FACILITIES

PART 820 SWIMMING FACILITY CODE

SECTION 820.210 SWIMMING FACILITY WATER TREATMENT SYSTEM

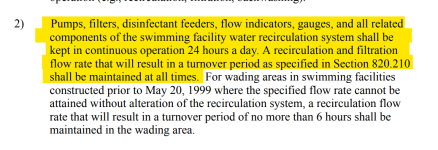

Section 820.210 Swimming Facility Water Treatment System

a) General Requirements

1) A water treatment system, consisting of pumps, piping, filters, water conditioning, disinfection equipment and other accessory equipment shall be provided to clarify, chemically balance and disinfect the swimming pool water. The system shall be designed for a recirculation flow rate that will result in a turnover period in each pool not exceeding those specified below. Systems serving pools with skimmers shall be designed for a flow rate of at least 30 gallons per minute for each skimmer.

Type of Pool | Maximum Turnover Period |

| Diving Pools | 8 Hours |

| Wading Pools, Wading Areas | 2 Hours |

| Plunge Pools and Plunge Areas for Water Slides | 2 Hours |

| Lazy Rivers | 2 Hours |

| Other Pools | 6 Hours |

| Spas | 30 Minutes |

I don't see any place in the Code where it says the flow rate may be reduced when bathers are not present and have been told on several occasions that the required flow rate must be maintained at all times.

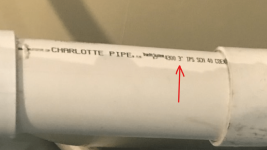

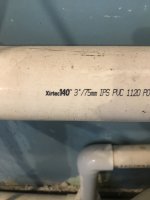

My apologies.... definitely 2" pipe the technician thinks is restricting flow (not 1") and thinks should be replaced with 3" pipe. He wants to connect the two 2" pipes coming out of the filters to a 3" T and replace 2 sections (about 40" total) of 2" pipe with 3" pipe and will also include two 3" elbows. See attached pics.

Do you agree that that work would probably help increase the flow rate?

Also.... see arrow on pump. I can confirm it is spinning in the right direction. I think we can put that issue to rest.

Do you agree that that work would probably help increase the flow rate?

Also.... see arrow on pump. I can confirm it is spinning in the right direction. I think we can put that issue to rest.

Attachments

It looks like you are correct.

In my opinion, it is ridiculous to keep the pump running at 167 GPM 24/7.

It is a huge waste of energy.

However, if it is the law, then I am not going to say to do otherwise.

ilrules.elaws.us

ilrules.elaws.us

In my opinion, it is ridiculous to keep the pump running at 167 GPM 24/7.

It is a huge waste of energy.

However, if it is the law, then I am not going to say to do otherwise.

§820.340. Operation and Maintenance, SUBPARTD. OPERATIONAL REQUIREMENTS, PART820. SWIMMING FACILITY CODE, TITLE77. PUBLIC HEALTH, Illinois Administrative Code

The compilation of all agency rules is known as the Illinois Administrative Code. The Code, which is larger than the Illinois Compiled Statutes, is maintained electronically by JCAR/LIS. And it is updated weekly by the Illinois General Assembly.

The 2" pipes coming out of the filters are ok as long as they T into a 3" T.

A 2" pipe can take up to 84 GPM each for a total of 168 GPM.

If the 2" pipes go into a 2" T, then that should be changed.

I would not have more than 8 feet per second in the return lines.

Actually the code says 10 feet per second, but I would try to stick to 8 feet wherever possible.

ilrules.elaws.us

ilrules.elaws.us

A 2" pipe can take up to 84 GPM each for a total of 168 GPM.

If the 2" pipes go into a 2" T, then that should be changed.

I would not have more than 8 feet per second in the return lines.

Actually the code says 10 feet per second, but I would try to stick to 8 feet wherever possible.

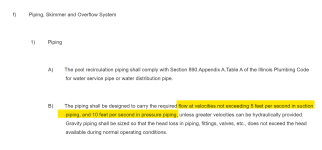

B) The piping shall be designed to carry the required flow at velocities not exceeding 5 feet per second in suction piping, and 10 feet per second in pressure piping, unless greater velocities can be hydraulically provided.

§820.210. Swimming Facility Water Treatment System, SUBPARTC. SWIMMING FACILITY DESIGN REQUIREMENTS, PART820. SWIMMING FACILITY CODE, TITLE77. PUBLIC HEALTH, Illinois Administrative Code

The compilation of all agency rules is known as the Illinois Administrative Code. The Code, which is larger than the Illinois Compiled Statutes, is maintained electronically by JCAR/LIS. And it is updated weekly by the Illinois General Assembly.ilrules.elaws.us

PART820. SWIMMING FACILITY CODE, TITLE77. PUBLIC HEALTH, Illinois Administrative Code

The compilation of all agency rules is known as the Illinois Administrative Code. The Code, which is larger than the Illinois Compiled Statutes, is maintained electronically by JCAR/LIS. And it is updated weekly by the Illinois General Assembly.

So what the technician is telling me makes sense.... that the 2" pipes coming out of the two filters should connect into a 3" T... and that should connect to 3" pipe and elbows throughout the return line.... instead of it connecting to a 2" T and 40 inches of 2" pipe before it goes into 3" pipe. Is that correct? He was puzzled as to why anyone would have plumbed it that way in the first place. If that section of the plumbing is corrected, do you have a guess on how much our flow might increase?The 2" pipes coming out of the filters are ok as long as they T into a 3" T.

A 2" pipe can take up to 84 GPM each for a total of 168 GPM.

If the 2" pipes go into a 2" T, then that should be changed.

I would not have more than 8 feet per second in the return lines.

Actually the code says 10 feet per second, but I would try to stick to 8 feet wherever possible.

I looked at my own electric bill this past month and divided the total bill for the month by the total kw hours used and got 13.50 cents per kwh. So here's my calculation to run our outdoor pump for the season:Request a copy of the places monthly electrical bill. That will show you the cost/kwh and all other surcharges per kwh.

3.7 x .1350 x 24 = $11.98 per day x 112 days (16 week season) = $1,342.66. So.... about $1,350 to run the pump for the season. Sound about right?

I assume I could use the same formula to get the cost of running our indoor pump... Check the pump label for KW on the label (which will be lower since it's a smaller pump), but multiply the daily rate I calculate by by 365 since it runs all year long. Sound right?

Last edited:

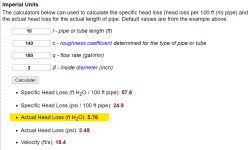

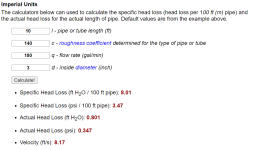

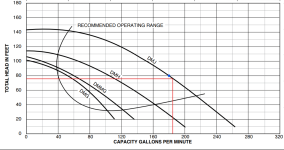

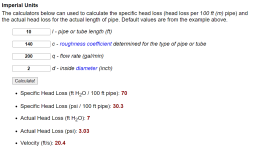

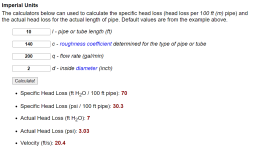

10 feet of 2" pipe (equivalent) creates about 5.76 feet of head loss at 180 GPM, which is about 2.49 psi.If that section of the plumbing is corrected, do you have a guess on how much our flow might increase?

10 feet of 3" pipe (equivalent) creates about 0.801 feet of head loss at 180 GPM, which is about 0.347 psi.

The difference will be about 4.96 feet of head or 2.14 psi, so the flow will improve by about 2 GPM.

Last edited:

Hazen-Williams Water Flow Formula: Head Loss, Data, Charts & Calculator

Friction head loss (<i>ft<sub>H2O</sub> per 100 ft pipe</i>) in water pipes can be estimated with the empirical Hazen-Williams equation.

Last edited:

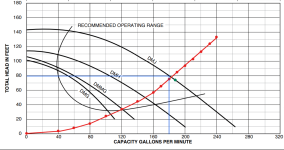

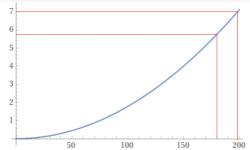

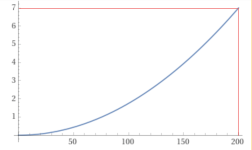

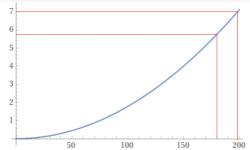

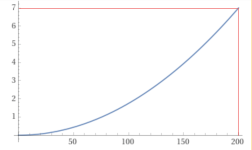

10 feet of 2” PVC has a curve of about 0.00017778X^2.

10 feet of 3” PVC has a curve of about 0.00002472X^2.

If the system has a curve of 0.00246914X^2 with the 10’ of 2” PVC, the new system will be 0.00246914 - 0.00017778 + 0.00002472 = 0.00231608X^2.

0.00231608/0.00246914= 0.938 = 93.8%

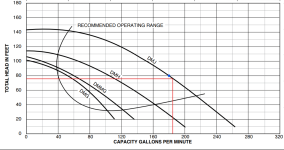

If the old operating point was 80 feet of head at 180 GPM, the new operating point will be about 182 GPM at about 76.7 feet of head.

So, you should gain about 2 GPM and the pressure should go down by about 1.4 psi.

You might, or might not, see a difference in the flow.

In my opinion, the flow is somewhat uncertain as we are getting two different readings.

However, the higher flow is more consistent with the pump performance curve assuming the pump is working as expected.

10 feet of 3” PVC has a curve of about 0.00002472X^2.

If the system has a curve of 0.00246914X^2 with the 10’ of 2” PVC, the new system will be 0.00246914 - 0.00017778 + 0.00002472 = 0.00231608X^2.

0.00231608/0.00246914= 0.938 = 93.8%

If the old operating point was 80 feet of head at 180 GPM, the new operating point will be about 182 GPM at about 76.7 feet of head.

So, you should gain about 2 GPM and the pressure should go down by about 1.4 psi.

You might, or might not, see a difference in the flow.

In my opinion, the flow is somewhat uncertain as we are getting two different readings.

However, the higher flow is more consistent with the pump performance curve assuming the pump is working as expected.

Last edited:

2" PVC does create a restriction, but not as much as people might think.

For 10' of 2" PVC at 200 GPM, the velocity is about 20.4 feet per second and the head loss is about 7 feet or about 3 psi.

www.wolframalpha.com

www.wolframalpha.com

www.engineeringtoolbox.com

www.engineeringtoolbox.com

www.wolframalpha.com

www.wolframalpha.com

For 10' of 2" PVC at 200 GPM, the velocity is about 20.4 feet per second and the head loss is about 7 feet or about 3 psi.

y = 0.00017778x^2, x from 0 to 200 - Wolfram|Alpha

Wolfram|Alpha brings expert-level knowledge and capabilities to the broadest possible range of people—spanning all professions and education levels.

Hazen-Williams Water Flow Formula: Head Loss, Data, Charts & Calculator

Friction head loss (<i>ft<sub>H2O</sub> per 100 ft pipe</i>) in water pipes can be estimated with the empirical Hazen-Williams equation.

y = 0.000175x^2, x from 0 to 200 - Wolfram|Alpha

Wolfram|Alpha brings expert-level knowledge and capabilities to the broadest possible range of people—spanning all professions and education levels.

1.12 kW is = 1.5 HP, but that is not how much power it uses, that is the power transferred to the water.

That pump will be closer to about 2.2 Kw actual power used.

That pump will be closer to about 2.2 Kw actual power used.

In the picture, you can see that the total HP is listed as 2.2.

The kW is usually = to the total HP, not the label HP.

2.2 total HP = 2.2 kw.

2.2 x 0.1350 = $0.297 (per hour) x 24 hours = $7.128 (per day) x 365 days = $2,601.72 per year

Per week = $50.03. Per month = $216.81.

Also, the volts x amps = watts.

230 x 10.4 = 2,392 watts.

That is the maximum power the pump should ever be loaded to.

However, the actual load is usually lower by maybe 5 to 10%.

0.92 x 2,392 = 2,200 watts.

The kW is usually = to the total HP, not the label HP.

2.2 total HP = 2.2 kw.

2.2 x 0.1350 = $0.297 (per hour) x 24 hours = $7.128 (per day) x 365 days = $2,601.72 per year

Per week = $50.03. Per month = $216.81.

Also, the volts x amps = watts.

230 x 10.4 = 2,392 watts.

That is the maximum power the pump should ever be loaded to.

However, the actual load is usually lower by maybe 5 to 10%.

0.92 x 2,392 = 2,200 watts.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.