I don’t remember where I got those numbers I’m going to try to research the details on the pump. The sump is so that the pump can’t create a suction more than just a gravity flow drain. Another way I have read about is just to put a T in the line between the pool and the intake of the pump that would suck air in the event that the grate was blocked.

10 hp pump for a slide on new vinyl liner pool

- Thread starter Garfield

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Darin

Well-known member

- May 29, 2015

- 556

- Pool Size

- 35000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

Phase converters are really not used anymore on new installs as vfd's have come down in price. Looks like an old durco pump which is a good pump. You could always slow it down with a vfd so you dont blow kids in the yard.

Looks like the part of the pic that you need is on the left side partially cut off. The right side is 10 hp with 190/380 V feed. the left is 230/480 feed and is labeled 15 hp. Better be sure you really want huge sucker becasue the needed VFD just went up in price.

Looks like the part of the pic that you need is on the left side partially cut off. The right side is 10 hp with 190/380 V feed. the left is 230/480 feed and is labeled 15 hp. Better be sure you really want huge sucker becasue the needed VFD just went up in price.

Last edited:

Good catch on needing the other part of the label. My memory said that was a 15 horse pump so I was kind of annoyed when I found out it was 10 hp. I’m gonna have to tell my wife about this, that I was right after all. I have what I need to make a rotary phase converter so likely I’ll try that first and if the rpm is unacceptable then I’ll look at the VFD.

- Feb 17, 2022

- 399

- Pool Size

- 12000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Just my two cents, but that looks like it could be an ANSI centrifugal pump where the impeller and casing are made by another manufacturer than the motor. There should be a tag or some in the casting of the casing stating the brand and model.

Darin

Well-known member

- May 29, 2015

- 556

- Pool Size

- 35000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

If you were to switch to single phase your inrush current would be huge, not to mention the size of conductor you would need. Plus the only way to control would be to pinch the discharge valve. Not the end of the world though.

Last edited:

In my opinion, you do not need a separate sump as long as you get a main drain rated for the flow and certified to APSP-16-2017.

You can get a main drain rated for double the flow if you want to be extra safe or use two or more main drains.

As long as you have enough drain surface area, the grates should not be blockable by one person.

Here's one that can do 2,401 GPM.

Get two if you want to be extra safe and separate them by 3 feet.

www.recreonics.com

www.recreonics.com

You can get a main drain rated for double the flow if you want to be extra safe or use two or more main drains.

As long as you have enough drain surface area, the grates should not be blockable by one person.

Here's one that can do 2,401 GPM.

Get two if you want to be extra safe and separate them by 3 feet.

VGB - Swimming Pool and Spa Safety Act Compliant Main Drain Sumps

Our main drain sumps are compliant with the Virginia Graeme Baker Pool and Spa Safety Act which was enacted to prevent body suction and entrapment.

i talked to an engineer friend and he suggested putting a 16 inch ( to lower velocity) pvc pipe out the side of the pool with appropriate grating that would then go to a vent above grade about 10 feet out then reduce to the 6 inch that feeds the pump. This would limit the maximum potential suction to just gravity flow water because in the event that the grate was plugged it would suck air. If I do this how do I seal the 16 inch pvc coming into the vinyl liner?

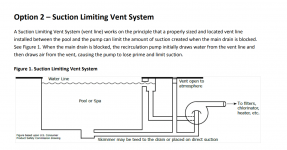

A Suction Limiting Vent System can work, but it leaves a lot of stagnant water.

It has to be designed by a licensed engineer and approved by your local inspector.

I would not use a Suction Limiting Vent System.

Any grate/sump has to be certified to APSP-16-2017 or custom designed by a licensed engineer and approved by your local inspector.

It has to be designed by a licensed engineer and approved by your local inspector.

I would not use a Suction Limiting Vent System.

Any grate/sump has to be certified to APSP-16-2017 or custom designed by a licensed engineer and approved by your local inspector.

It's only about $7,000.00 for two.I like the idea but not the price!

"Gravity drainage systems are not discussed here" it says in that article. I believe this is what I am referring to with a Tee on it's back and a full size 16 inch pipe to the atmosphere it will be the same hydraulically as if I had a pit. The diagram in the article is relying on smaller pipes and a trap effect so the pipe can still have suction above what gravity would allow.

Can you draw a diagram of what you are proposing?I believe this is what I am referring to with a Tee on it's back and a full size 16 inch pipe to the atmosphere it will be the same hydraulically as if I had a pit.

You would need to put the pump below the pool to have a flooded suction where there is no vacuum created (below 0 gauge pressure).

Any vacuum created would cause the vent to pull in air.

In any case, the entire design needs to be done by a licensed engineer and approved by your local inspector.

- Feb 6, 2015

- 7,843

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

It may be best to look into the insurance aspect first - instead of spending money on engineering, permitting and parts only to find out no insurance company will provide coverage for a realistic price.

- May 23, 2015

- 25,721

- Pool Size

- 16000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Maybe off topic but similar to Gene’s question … given the size of the slide involved and the unusually large sized pumps required as well as the very large flow rates - do you thing your city or municipality will actually allow this? Maybe you live in an area with little building oversight, I don’t know, but KC Missouri seems like a place where the building inspectors would be pretty tough (I have family that lives on the Kansas side of KC). Have you talked to the relevant building authorities in your area? Might be worth a trip to their office.

That might work, but you would need an engineer to design it and it would have to be approved by your local inspector.This is what I was trying to describe.

- May 3, 2007

- 18,089

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

If you can get the diameter of the impeller, you can estimate the head curve. Based on the pictures and the HP, it looks to be around 8.5". If so, then the run out will be around 600-650 GPM so no where close to 1200 GPM. However, to prevent damage to the pump, you generally don't want an operating point more than about 120% of BEP which is around 510 GPM. So a target operating point of 510 GPM @ 50' of head. Assuming the head curve below is representative. But most likely the plumbing you have chosen will have much more head loss than that and the flow rates will be lower than 500 GPM. How long will the pipe runs be?

I would suspect that the city would require a design done by a licensed engineer for the entire project.KC Missouri seems like a place where the building inspectors would be pretty tough

Kansas City is the closest city you have heard of not where I'm located. Thanks though for the insight.

The pump is currently in a barn that's 1/2 mile down a mud road so if it dries a little I will look closer at impeller size. That's good info.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.