- May 3, 2007

- 18,089

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Also check if there is a model number stamped on the wet end housing.The pump is currently in a barn that's 1/2 mile down a mud road so if it dries a little I will look closer at impeller size. That's good info.

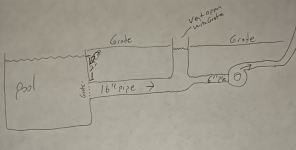

Also, regarding the vent, if the connection can be closer to the MD, then you don't need to use as large a pipe. The only reason for the larger pipe is to minimize the head loss between the drain and the vent connection. Once you figure out what pump you have, the plumbing layout, we can estimate flow rates and appropriate design for the vent.