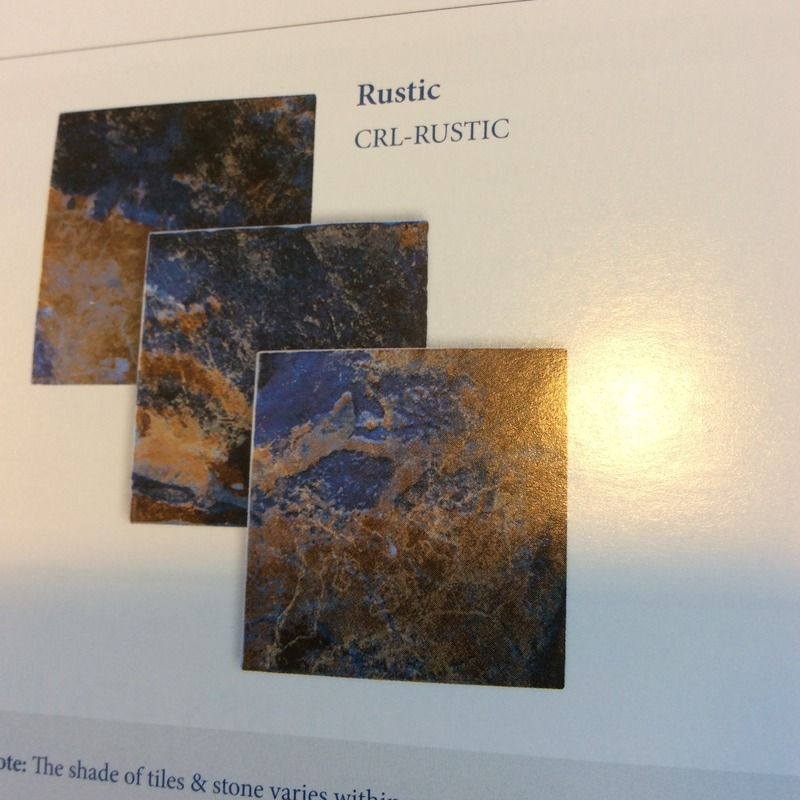

Welllllllllllllll I am a girl and I love BLING! See how some of that pretty blue, glass tile will look next to it with a sample of the plaster. Of course I am sure it will be an up charge so........

Kim

Kim

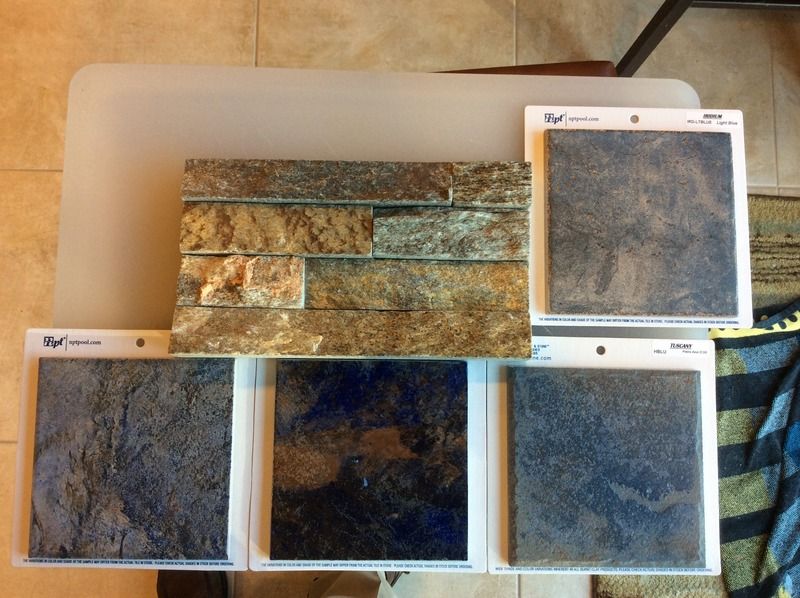

What about something like THIS? Looks like all of your colors...

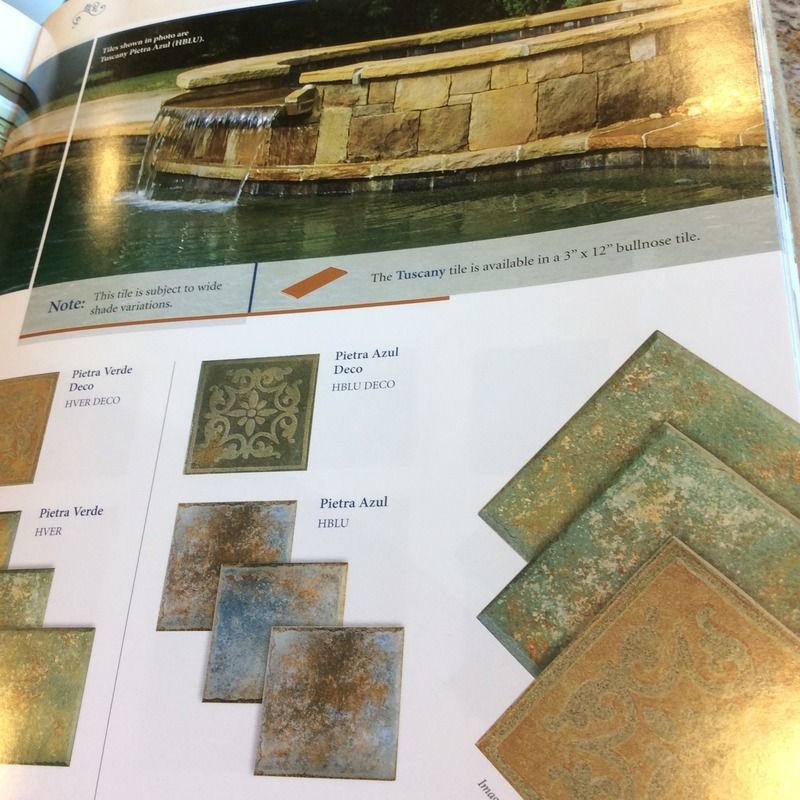

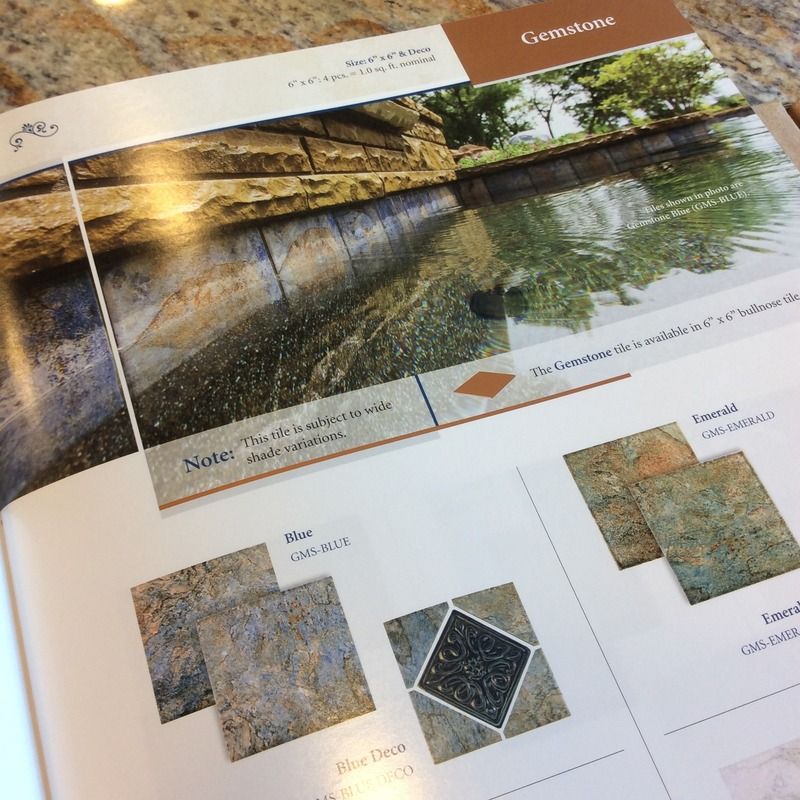

I used the gemstone blue on my new bird. It is nice. We are happy

Sent from my iPhone using Tapatalk

Can you share so photos that show the tile water in sun?

thanks!!

Kim, gemstone does not have enough variation to worry about a layout. I did this and you cannot really tell much difference in the tiles. For other tiles this would be important.

Sent from my iPhone using Tapatalk

Was the tile for your pool pretty much the same patterns and color blends as the samples posted above in the showroom and catalog? I think we are going with the Gemstone Blue just wondering it I need to go down to the distribution center to make sure what shows up is not 180 degrees different.

I never recommend saw cutting the concrete. By the time the cuts are made, the concrete has already cracked. The tooled joints are put in while the concrete is wet and serve as a void for the shrinkage cracks.

I am a big fan of irregular and curved joints. This will help to soften up the appearance and more importantly allows you to place joints exactly where you know the concrete will crack which nearly eliminates random cracking elsewhere.

I really would advise against that much rebar especially if you are also using fiber. Rebar does nothing to prevent cracks and in my experience, the voids it creates increases the potential for more cracking. The 12x12 grid around the perimeter is required but beyond that none is needed. If you want to go with that much rebar, the slab needs to be 6" thick.

For a quality job, specify a 4" slump maximum, no additional water applied and a dry base. Expect a lot of resistance from the contractor on this.

I've poured several driveways 4" thick at 3000 psi without a single piece of rebar and have 0 cracks with very beach traffic

You have saved me SO much time and effort it's unbelievable, thank you.

Okay, so tooled joints. Will need to get more detail on the 4" Slump? They can push the rebar to 24" OC in the field. I feel sorry for people who do not use this fourm as a resource.