Yayyy, from JamesW's experience, we finally learned how the pump knows it's flow

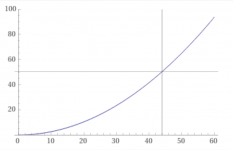

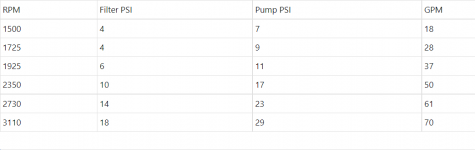

. Sounds like the pump's brainbox converts power draw to an expected PSI, and therefore flow, knowing its RPM.

And we've also learned from your very helpful testing that the pump is wrong in its own expression of PSI by about 30%, assuming your pressure gauge is likely to be close to correct, which I think is a reasonable assumption. You would only expect that to be lower by a small fraction of one PSI (pressure loss in pipe from pump to multiport), if the pump's brain was correct. (I'm also assuming your pressure gauge reads zero when the system is off, and that it's reasonably new).

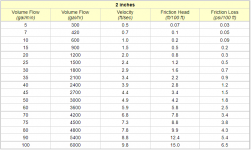

Point being that if your pump is calculating pressure higher than it actually is, it's also calculating flow that's lower than it actually is. It would respond by spinning faster to achieve the flow rate it's been asked to achieve by way of your flow setting.

So if it were mine, I'd turn that gobbledygook off, and run it based on RPM. There's a strong possibility that there's no practical problem here at all (other than that intelliflo VF pumps aren't fantastic at calculating their flow rate).

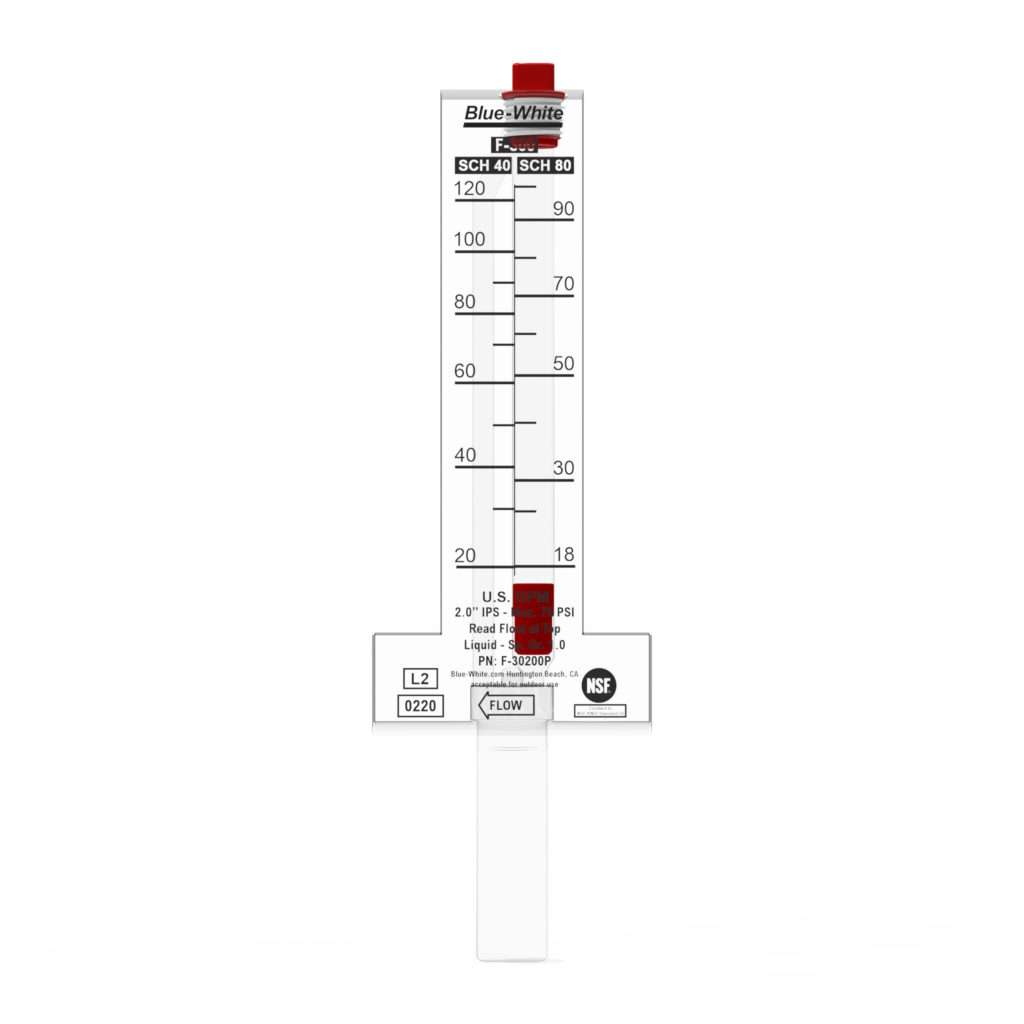

Alternately, you could set flow rates low. A possible problem with that is the minimum 20 GPM in the settings, which might truly be delivering more like 25-27 GPM, more than you need for the SWCG. Conversely 20 GPM (the pump believes itself to be) is a nice low end safety limit for your heater, which is spec'd at a minimum flow of 25 GPM.

I have huge respect for the posters and information you're getting, and if you're enjoying the exploration and don't mind some cost, that's great too, because the rest of us following along are learning heaps here.

Your suction will be around 5 inHg higher than average circumstances because of the 6 foot lift (IIRC) from pool to pump.