| Line 119: | Line 119: | ||

===Pipe Size and Flow Rates=== | ===Pipe Size and Flow Rates=== | ||

| − | + | Choosing the correct pipe size is very important for high efficiency plumbing. Ideally, it is best to keep suction pipe velocity below 6 ft/sec and return pipe velocity below 8 ft/sec. This helps prevent suction side issues such as entrapment and air leaks. Also, it is a good idea to have a separate suction line from each skimmer and/or main drain pair from the pool all the way to the pump so that one can isolate suction lines if necessary. | |

| + | |||

| + | The water velocity in a pipe is determined by the size of the pipe and the flow rate going through the pipe. Below is a table of common pipe sizes and the recommended flow rates for two different velocity specifications. | ||

{| class="wikitable" | {| class="wikitable" | ||

| Line 157: | Line 159: | ||

|} | |} | ||

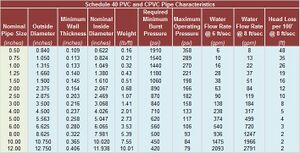

| + | This is a more detailed summary of pipe characteristics: | ||

| + | [[File:Pipe Characteristics.jpg|thumb]] | ||

| + | |||

| + | Another way to reduce water velocity in pipes while maintaining high flow rates is to use multiple parallel pipes. The table below shows the equivalent diameter of pipe for multiple pipes of another diameter and equal lengths. N is the number of pipes from 1 to 10 and across the top is the diameter of each pipe. The values within the table are the equivalent diameter for a single pipe. | ||

| + | [[File:Multiple Pipes Equivalent Size.png|thumb]] | ||

As you can see, the head loss difference at 30 gpm is only about 0.9 feet, which is not very significant. | As you can see, the head loss difference at 30 gpm is only about 0.9 feet, which is not very significant. | ||

Revision as of 19:41, 11 October 2024

What are the Best Practices for a Pool Equipment Pad?

If you are building your pool there are many best practices to discuss with your builder and contractor.[1] One of them is the Pool Equipment Pad which will house your pumps, filter, pool heater, and related equipment. Before using the tips below, always check your local code and safety requirements or restrictions.

Location and Layout

Consider the location carefully so that it is both easily and quickly accessible. Many Pool Builders will put the equipment where it is convenient for them. Have it put where you will be able to access it easily and quickly if needed. The equipment pad should be a reasonable distance from the pool so that you can move between the pool and equipment without a long hike.

In an area of hot sun, like the SouthWest US, place the equipment north facing and out of the direct sunlight. Not in a direction where the equipment will be cooked and baked by the hot desert sun 24/7/365. It is worth spending more to locate the equipment in the coolest area. Otherwise the sun can age equipment in 10 years like 30 years.

Most pads require a minimum of a 4’x4’ area and depending on the equipment it could be up to a 5’x10-12’ area or larger. A pool pad can be too small to easily work with the equipment after it is installed, while the pad is rarely too large. You will be the one working around the pool equipment on the equipment pad, not the Pool Builder or plumber, so make sure you have adequate space.

A typical equipment pad layout is pumps on one side, filter in the middle, heater on the other side and pipes from the pool coming up from gravel along the side of the equipment pad. There should be enough spacing between and around equipment for regular service and repairs including access at the rear of the pumps. Room to move around means you should be able put your feet between the equipment and pipes and behind all equipment.

The plumber should place the equipment for the least amount of turns in the pipes as possible. That is an art into itself and some plumbers are better at equipment layout and pipe runs then others. A good plumber will leave extra pipe and straight runs between joints allowing space for cuts in the PVC to be made for repairs or additional equipment. The pipes coming out of the ground next to the equipment pad should have at least 6”, if not more, of pipe above ground before a 90 degree fitting or valve is glued onto it. Some plumbers will cut those pipes close to the ground leaving little extra pipe for when the valve needs to be replaced or the plumbing changed.

The equipment pad should be raised at least slightly from the surrounding ground for water drainage. Your property’s storm run-off and surrounding ground conditions are of particular importance in choosing the location. Additionally, a solid structure, such as an existing wall or new wall created by posts and 2 x 10’s, will be necessary for mounting control panels.

A side note on working with contractors — some will take direction well on what the customer wants, while others will bristle and tell you about all their years in the business and they know how to do things. Few contractors like their customer trying to tell them how to do their job. It is best to ask probing questions to discover what you should expect. And then keep a watchful eye on the work and see if it is meeting your expectations. PVC is cheap and changes can be made easily if they are immediately brought to the contractors attention. Providing water, coffee, doughnuts, or pizza goes a long way to getting contractors to put extra effort into your project. Make your project a place the contractors enjoy working at.

Equipment Pad Surface

The equipment pad should be of poured concrete and not simply some composite pads layed on the ground. No pipes should come up through or be under the concrete pad. Instead, bring pipes up through crushed stone on the side of the concrete pad to allow easy access for repairs in the future.

Anchoring Equipment

In Florida, some equipment is required to be anchored.[2]

The rules are not super clear on what is supposed to be bolted down and what it not required to be bolted down.

Anchoring can help prevent theft, vibration and wind damage.

Using a sheet of rubber below the pump before anchoring can help reduce vibration.

The Pentair MasterTemp Installation Manual says "In Florida, building codes require that the heater be anchored to the equipment pad or platform to withstand high wind pressures created during hurricanes. A Bolt Down Bracket Kit, P/N 460738, is available with anchor clamps designed to hold the unit to the equipment pad in high wind conditions. Installation of the anchor clamps are recommended in all installations and are required in Florida, (See Florida Building Code 301.13)".

"301.12 Wind resistance. Mechanical equipment, appliances and supports that are exposed to wind shall be designed and installed to resist the wind pressures on the equipment and the supports (FL’s) as determined in accordance with the Florida Building Code, Building".

Ventilation and Sun Protection

Good airflow is important to your pool equipment’s lifespan and proper operation. Heaters need a high volume of air intake to operate properly and you need to consider where the hot heater exhaust will blow if you have a gas heater.

Pool equipment and pipes need to be protected from the sun, especially in areas of intense sun like the Southwest USA. The suns UV rays reduce the impact resistance of PVC pipes over time.[3] UV also causes a brown discoloration on PVC pipes. At a minimum the PVC pipes should be protected from the sun's UV rays by spray painting the pipes.

If you have decided to have an enclosed pool pad you could use a 3’-4’ fence with a small roof. Special considerations need to be given when enclosing a pool heater both for sufficient air intake and for the exhaust of a gas heater.

While not necessary, it is common for a small, short fence or shrubs or plantings to be built on two or three sides to conceal equipment and act as a slight noise barrier for the pool pump.

Electrical

Pool Pad Outlet

At least one 120V GFCI receptacle near the pool equipment pad is among modern best practices. Many automation panels have a space for a 120V GFCI receptacle in their Load Center.

Pool Pad Floodlight

In addition, a switched overhead LED floodlight will allow you to check equipment at night. The overhead equipment pad light can be turned on and off through an automation panel if you have one.

Use Grey Electrical Conduit

Electrical lines for the pool lights from the pool to light junction boxes or to the equipment pad must be run in grey electrical schedule 40 PVC pipe which is different then white water schedule 40 PVC pipe.

NEC Article 352. The Rigid Non-metallic Conduit, elbows and associated fittings must be listed.

No More Then 360 Degrees of Bends

Water pipe 90's should never be used on electrical PVC conduit as they are way too tight of a bend for pulling wire. Instead grey schedule 40 PVC electrical sweeps which have a much larger radius should be used. Or as an alternate, 1" PVC conduit can be bent by heating. There are heat boxes made for this purpose.

No more than a total of 360 degrees before a junction box/ hand hole is allowed by the NEC. NEC 358.26 - Bends — Number in One Run. “There shall not be more than the equivalent of four quarter bends (360 degrees total) between pull points, for example, conduit bodies and boxes.”[4]

For conduits with an internal diameter of 2 inches or less, the inside radius of a bend in conduit shall be at least 6 times the internal diameter.[5]

The portion of the electrical conduit in the ground and/or below the top of the coping must be water tight.

Load Center Electrical Shutoff

Install a single 60 to 120 AMP breaker in an enclosure beside the Load Center. This will save many trips to the main house panel to disconnect the Load Center before you touch any high voltage wiring.

Pool Light Junction Boxes

The best is to locate a pool light junction box near the pool and the conduit rises up fairly rapidly. That minimizes the wire pull needed to install and replace a light.

Place multiple junction boxes around the pool to minimize the light wire pull for each light. The people replacing pool lights in that pool for the next 50 years will thank you.

It may be difficult finding a good place for the light junction boxes around some pool designs but many builders don't try hard enough to find a suitable location. They leave the problems of long light wire pools when lights need to be replaced to others after they are long gone.

Water Around the Equipment Pad

A water spigot connected to house water should be convenient to the equipment pad for cleaning your filter and priming the pump.

Working around pool equipment can be a wet process. Identify where water will drain to when you need to clean the filter. Should any of the pool equipment spring a leak where will the water run to until you discover it and can turn the equipment off?

If you have a DE Filter or Sand Filter it will need to backwashed occasionally. Backwashing runs pool water through the filter medium to remove the dirt and drains the dirty water out a waste line. Determine where the waste line will dispose of the effluent and if your local codes allow the backwash line to be connected to your sewer line.

If you do not have an overflow drain in the pool you will need a convenient way to drain some pool water after storms or sustained rainy times. This maybe from a waste line into a sewer drain if your local codes allow or a spigot through a hose. Consider where the water will run to as it can be hundreds of gallons.

Plumbing

For a deeper dive into pool plumbing design read Pump Plumbing Head Curves and Operating Points.

Pressure Testing the Pipes

Take all the pipes after being laid in the trench and join them together to make a pressure test configuration with the pool side fittings plugged. Pressure test the plumbing for 24hrs minimum then backfill under pressure. The pipes move when back-filling. Leave the pressure test rig on for a few days and water the trenches to help settle and hand tamp them as you fill if narrow. After all that cut them and do the pad plumbing using diverter valves.[6]

Water Velocity

There are primarily three reasons to be concerned about water velocity in plumbing:

- High water velocity can result in high head loss.

- High water velocity in suction lines and main drains can increase the risk of entrapment.

- High water velocity can also increase the risk of hydraulic shock (water hammer) which can cause damage to plumbing weld joints.

To address these issues, you will sometimes see web sites quote recommended maximum flow rates in piping usually in the range of 5 ft/sec to 10 ft/sec for PVC piping. However, it is important to understand that these are only recommendations and not hard limits. In other words, if you can find a big enough pump, the flow rate can and will exceed these velocity recommendations. There is no fundamental limit to how fast water will travel in pipe.

Increasing the pipe size in plumbing will usually result in lower head loss but there are diminishing returns because the pipe is only part of the total head loss. Filters, heaters, valves, skimmers, main drains and return eyeballs all contribute to the total head loss of the plumbing. In general, it is a good idea to go with at least 2" plumbing in a pool system and ideally using 2.5" to add some efficiency. For spa jets which require high flow rates, 2.5" should be considered the minimum with 3" pipe providing better flow rates for the jets.

Issues of entrapment are addressed by the Virginia Graeme Baker Act and the ANSI/APSP-7 standard which state that for residential pools, the water velocity should not exceed 6 ft/sec in the piping within 3 feet of a suction port and 8 ft/sec in the line going back to the pool. This is easily accomplished with large piping which should be done to limit head loss anyway.

As for water hammer, high flow rates in plumbing have the potential to damage plumbing should a valve close suddenly. Repeated stress cycling of PVC pipe will eventually cause failures and the cycles to failure is directly dependent on the average pressure of the pipe and amplitude of surge pressure in the pipe. Fortunately, failures due to water hammer are fairly rare events in pool plumbing so there is not too much to worry about.

Pipe Size and Flow Rates

Choosing the correct pipe size is very important for high efficiency plumbing. Ideally, it is best to keep suction pipe velocity below 6 ft/sec and return pipe velocity below 8 ft/sec. This helps prevent suction side issues such as entrapment and air leaks. Also, it is a good idea to have a separate suction line from each skimmer and/or main drain pair from the pool all the way to the pump so that one can isolate suction lines if necessary.

The water velocity in a pipe is determined by the size of the pipe and the flow rate going through the pipe. Below is a table of common pipe sizes and the recommended flow rates for two different velocity specifications.

| Pipe Size | 6 ft/sec | 8 ft/sec |

|---|---|---|

| 1.5" | 38 GPM | 51 GPM |

| 2" | 63 GPM | 84 GPM |

| 2.5 | 90 GPM | 119 GPM |

| 3.0" | 138 GPM | 184 GPM |

| 4.0" | 235 GPM | 312 GPM |

Here is the head loss in feet for 100 feet of PVC pipe at different flow rates for 2” and 2.5” pipe.[7]

| GPM | 2” | 2.5” |

|---|---|---|

| 30 | 1.6 ft | 0.7 ft |

| 40 | 2.8 ft | 1.2 ft |

| 50 | 4.2 ft | 1.8 ft |

| 60 | 6.0 ft | 2.5 ft |

| 70 | 7.9 ft | 3.3 ft |

| 80 | 10.2 ft | 4.3 ft |

| 90 | 12.6 ft | 5.3 ft. |

This is a more detailed summary of pipe characteristics:

Another way to reduce water velocity in pipes while maintaining high flow rates is to use multiple parallel pipes. The table below shows the equivalent diameter of pipe for multiple pipes of another diameter and equal lengths. N is the number of pipes from 1 to 10 and across the top is the diameter of each pipe. The values within the table are the equivalent diameter for a single pipe.

As you can see, the head loss difference at 30 gpm is only about 0.9 feet, which is not very significant.

Even at 60 gpm, the head loss difference is only 3.5 feet per 100 feet of pipe.

As long as you follow the 6 feet per second rule for suction and 8 feet per second for returns, the advantage of upsizing the pipe is negligible for pipe runs less than 100 feet in length.

For pipe runs that are over 100 feet, you would want to calculate the head loss and size the pipe accordingly. Most people think that they need a bigger pump if the filter is far away. However, the pump size is the same regardless of how far away the pool is from the filter system. What matters is the plumbing size. The pump can be 1 foot or 1,000 feet away and the pump size will be the exact same. You only change the pipe size and especially on the suction since it can cavitate.

If you want to be conservative, you can use the 6 feet per second rule for the return side as well.

Skimmers should typically be designed to handle less than 50 GPM, so a 2.5" line will be about 7.2 feet of head at 50 gpm for 400 feet.

If you have 2 skimmers, you can get up to 100 gpm if you have a separate 2.5" line from each skimmer to the pump.

Returns are typically looped around the pool. if it cannot be achieved then the plumber will run a minimum of 18” of dead run past the last Tee to achieve back pressure.

PVC Pipes - Friction Loss and Flow Velocities Schedule 40

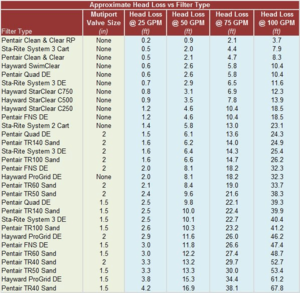

Head-Loss Specs for Pentair Multiport Valves

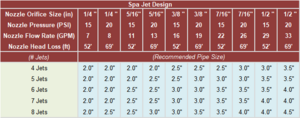

Spa Jet Design

The first step in designing a spa is to settle on the number of jets, size of jet and how strong you would like the jet to feel. Once this is determined, the following table can be used to determine the proper pipe size and the resulting operating point for the pump.[8]

The following example will help understand how to use the sizing table:

- Jet Design: 6 x 3/8" Jets @ 15 GPM/Jet

- Total Flow Rate = 90 GPM

- Minimum Recommended Pipe Size = 3.0"

- Head Loss ~ 37' (assumes 100' of pipe and typical fittings for a spa)

- Desired Pump Operating Point = 90 GPM @ 37' of head

Learn Pool Plumbing with Test Tank is a YouTube video from JMax Swimming Pool Plumbing that demonstrates how spa jets with an air venturi work. It also gives a great demonstration of pool hydraulics and what head is.

The Ultimate Guide to Gunite Jet Body Installation explains how gunite jet bodies are installed and jets assembled.

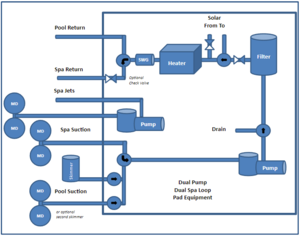

Spa Dual Pump Plumbing

When a spa has many jets a dedicated spa jet pump maybe needed to give adequate flow without the restrictions of a filter or heater. Below is typical plumbing for spas serviced by dual pumps.

One pump provides filtered and heated water to one or two spa returns. The other pump flows directly to the spa jets. Each pump has dedicated suction ports in the spa floor.

2 Inch PVC for the Equipment

If you have 2" fittings at the pump amd filter use 2" PVC for the equipment. Then make your return manifold out of 2" and then use 1.5X2" diverter valves as reducers to 1 1/2" return pipes.

Valves

Use re-buildable diverter valves such as from Jandy, Pentair, Hayward, or CMP . The "ball valves" found in big box stores are not recommended as they are problematic, stick over time, handles can break, and are difficult to repair.

Unions

All of the equipment should be connected with unions for cost savings over time, and for repairs to occur without cutting the pipes. The extra cost up front will prove useful the first time a repair is needed.

For Pentair pumps look for "2 PACK -CMP Hi-Temp Union 2" inch 2MIP x 2" inch PVC Whisperflo & Intelliflo - 2 PACK"[9]

Water Temperature Sensor

If you are having a pool automation controller then a water temperature sensor will be installed in the equipment pool plumbing.

The temperature sensor is placed in a 3/8" hole and clamped onto the PVC pipe using a worm clamp. Drill the hole using a 3/8" paddle bit. Don't use a brad point bit that may drop debris into the pipe. Best is to flush clean the pipe of debris after drilling the hole so nothing gets into downstream equipment or valves.[10]

Labeling of all Pipes and Valves

Additionally, all valves and pipes should be labeled for function and flow direction, with permanent labels or light engraving. For good measure take a picture and print it out in case the labels fade or fall off.

- ↑ https://www.troublefreepool.com/threads/design-your-dream-pool-pad.184681/

- ↑ https://www.troublefreepool.com/threads/intelliflo-pump-is-not-powering-on-after-power-surge.263540/post-2307258

- ↑ http://www.nacopvc.com/c/tech-info/the-effects-of-sunlight-exposure-on-pvc-pipe

- ↑ https://www.troublefreepool.com/threads/pool-light-electrical-conduit.258502/post-2259488

- ↑ https://www.troublefreepool.com/threads/pool-light-electrical-conduit.258502/post-2259509

- ↑ https://www.troublefreepool.com/threads/just-completed-rough-in-for-new-pool.202965/post-1791423

- ↑ https://www.troublefreepool.com/threads/experimenting-with-pipe-sizing-length-and-flows-considerations-for-new-construction.222204/post-1946824

- ↑ https://www.troublefreepool.com/threads/hydraulics-101-have-you-lost-your-head.830/

- ↑ https://www.amazon.com/PACK-Hi-Temp-Union-Whisperflo-Intelliflo/dp/B00AKMV4K8/ref=sr_1_1

- ↑ https://www.troublefreepool.com/threads/where-do-i-drill-the-3-8-in-hole-for-the-water-sensor.301902/post-2638334