- Jan 4, 2016

- 5,392

- Pool Size

- 44000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

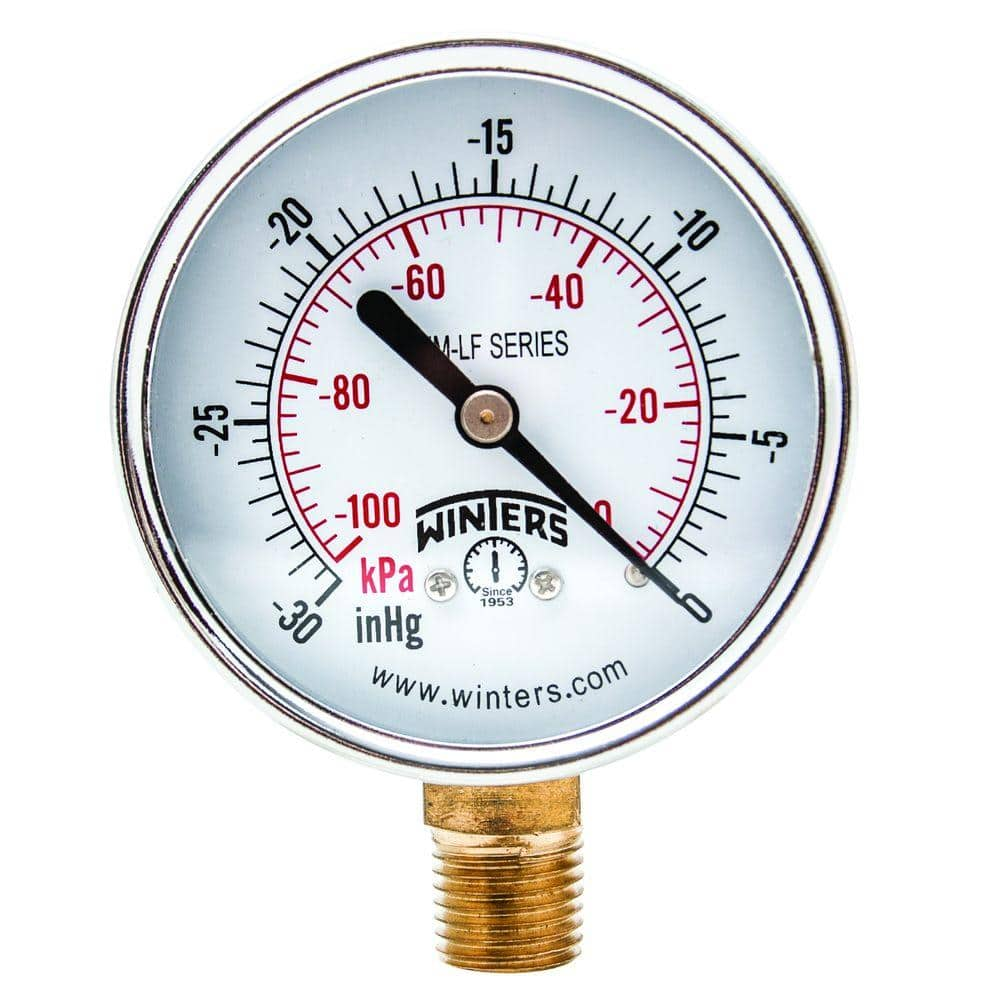

Kevin, I forgot to mention, in response to your concern about the pressure loss through the filter... the pump does 'work' to run your system, and that includes three main things (if you had water features, that would be additional 'work' to create aesthetic or other effects).

One part of the 'work' is to filter the water, one is to make the water in the pool move, and one is to overcome friction inside pipe and fittings. Filtering is a big part of the 'work', pushing water through small pore spaces, to catch the small floaties and make your water crystal clear. It's part of the job, and not alarming in any way, until the filter gets too dirty for the system to do a good job, at which point it gets backwashed.

One part of the 'work' is to filter the water, one is to make the water in the pool move, and one is to overcome friction inside pipe and fittings. Filtering is a big part of the 'work', pushing water through small pore spaces, to catch the small floaties and make your water crystal clear. It's part of the job, and not alarming in any way, until the filter gets too dirty for the system to do a good job, at which point it gets backwashed.