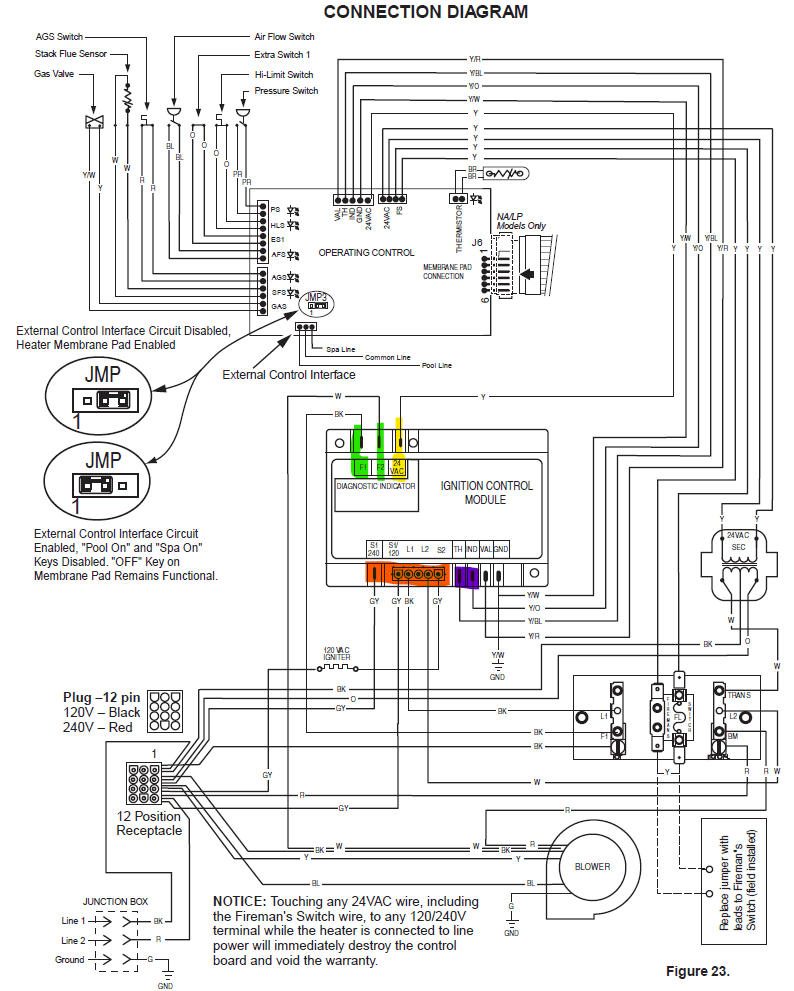

Hi, new here, and trying to avoid replacing my entire heater. I have a Pentair Mastertemp 400 (somewhere between 7 and 14 years old; I can't find the paperwork from the previous owner) that stopped heating b/c of an AFS light. I verified that the airflow sensor still works by blowing into the blower intake with a leaf blower (causing the light to go off). Also, the blower was obviously spinning freely. I also took off the blower shroud to verify that the blower is clear of debris and obstructions, and it's very easy to turn (and keeps turning when I stop blowing or pushing it, meaning the bearing seems fine).

However, when I start the heating cycle, the relay clicks and the blower moves ever so slightly (maybe a half inch) and stops, and the AFS light comes on.

Separately, bypassing the switch with a jumper wire hasn't worked. I'm pretty deep in troubleshooting...yesterday I was temporarily able to get the blower to come on by bypassing both the pressure switch (turns out it wasn't set correctly) and the AFS, but it made a weird deep pulsing noise while it was producing heat. I haven't been able to replicate that.

The igniter is reading 88 Ohms, and the circuit board appears to be fine based on other troubleshooting tips I've read around the web. My pump is good to go (although my salt has been too high for a while). My main filter was recently cleaned.

To narrow down my question, any idea what is keeping my blower from turning back on? Thanks in advance...I'd love to avoid a $4500 heater replacement!

However, when I start the heating cycle, the relay clicks and the blower moves ever so slightly (maybe a half inch) and stops, and the AFS light comes on.

Separately, bypassing the switch with a jumper wire hasn't worked. I'm pretty deep in troubleshooting...yesterday I was temporarily able to get the blower to come on by bypassing both the pressure switch (turns out it wasn't set correctly) and the AFS, but it made a weird deep pulsing noise while it was producing heat. I haven't been able to replicate that.

The igniter is reading 88 Ohms, and the circuit board appears to be fine based on other troubleshooting tips I've read around the web. My pump is good to go (although my salt has been too high for a while). My main filter was recently cleaned.

To narrow down my question, any idea what is keeping my blower from turning back on? Thanks in advance...I'd love to avoid a $4500 heater replacement!