If the air entering the heater is 80 degrees Fahrenheit and it exits the heater at 320 degrees, then it has gained 240 degrees.

If the heater is 84% efficient, the amount of heat that caused the temperature rise for a 400,000 btu/hr heater is about 16% of 400,000 btu/hr = 64,000 btu/hr.

If 64,000 btu/hr causes a 240 degree temperature rise, then 400,000 btu/hr will cause a 1,500 degree rise.

If the air entering the heater is 80 degrees and the temperature rises by 1,500 degrees, the combustion temperature is 1,580 degrees.

As the air passes the heat exchanger, 336,000 btu/hr transfers from the combustion gas to the water through the heat exchanger, which lowers the temperature from 1580 to 320 degrees.

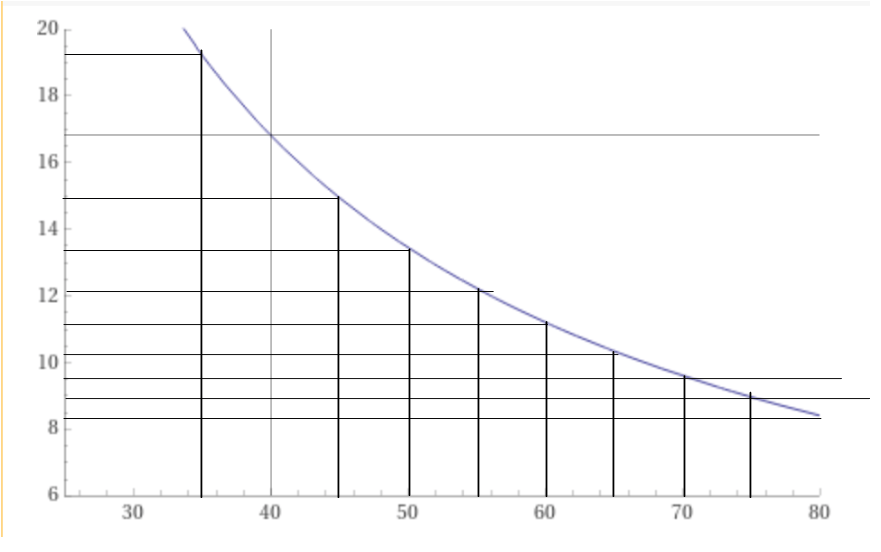

If you wanted to check the efficiency difference between the minimum flow and a higher flow, you could run the pump at the minimum flow and then check the exhaust temperature.

Then, increase the flow by 10 gpm or so and recheck the exhaust gas stack flue temperature.

If the stack flue temperature is lower at higher gpm, then that suggests that the efficiency is improved.

To check the stack flue temperature, turn the heater on. The fan will come on for about 30 seconds, then you will hear a click, and the heater should fire.

At that moment, which ever thermostat you are using (POOL or SPA) hold that button down for ~10 seconds.

Display should change from water temp to exhaust temp.

Normal temps should be in the range of 290-350.

Each degree lower represents about 267 btu/hr of extra heat saved.

267 ÷ 400,000 = 0.067%

For example, if the exhaust temperature went from 320 degrees to 310 degrees, that would be about 2,670 btu per hour or about 0.67%.

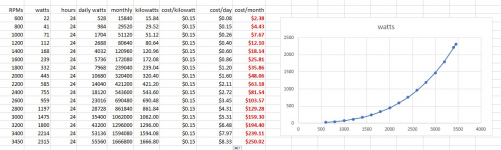

The cost to run a 400,000 btu/hr heater is about $3.81 per hour.

0.67% of $3.81 = 2.55 cents.

The cost to run a pump is about 10 cents per hour for 1,000 watts.

The breakeven point is if the extra pump power is 255 watts more.

In other words, if you increase the pump flow and it costs an extra 255 watts to get a 10 degree reduction in exhaust temperature, the savings in gas cost equal the extra costs in electricity.

If you can get a 1 degree reduction in exhaust temperature for less than 25 watts, it’s worthwhile increasing the pump speed.