If you CYA is really 140, the first order of business is to lower the CYA to 70. Only draining/refilling - half you pool volume - will lower the CYA to 70. After the refill, balance the water and retest the salt level.

Since my pool has a 12 year old vinyl liner I am trying to manage it with a SWG until its time for a liner change. Even if I wanted to change the liner now, that is going to be impossible and will take months based on family members experience, especially this time of the year. Hopefully by stopping the addition of CYA and CYA breaking down, it will get down to more managable numbers.

Allen, thank you, I will look into the chemical methods of determining the gallons, most likely I will get it as close as possible and then adjust based on pool math. I am going to take more detailed measurements and enter them into a grecian pool calculator I found.

Regarding the heater, yesterday I left it running and forgot to turn it off and when I checked it it said "No Demand - Water temp 120F". The heater and pool equipment is higher than the pool. Based on your info I wonder if the pressure switch is working properly, if it was, I would think it would cut off as soon as the pump stops pushing water, instead it appears to be heating the water left in the heater to the maximum/over the set temp and then shutting off? Or would it just prevent it from cycling back on with no flow? I may need to do more research on my exact model to determine if No Demand means the water has met the temp or it means the pressure switch has shut it off. I will check the pressure switch if i can find it with a multimeter as you suggested. I guess I could also watch the unit after the pump turns off and see if it starts up the heater without water flowing.... although it might take a while for the water to cool off inside it from 120F down to the cut out point.

I dont think the heater could be getting a cool down since the pump is cutting off and the heater doesnt know it, I dont see how the heater could know the pump is 5 minutes to shut down when just using a dumb timer that cuts the power, so I am going to assume this requires an automation system.

I will try to get some liquid chlorine to keep the FC around 8, can I use regular bleach in the pool with chloromax? I know I was told not to use clorox beacuse of the additives in the hot tub, but I assume its less of a problem in the pool? I will see if home depot has any pool chlorine when I am there today.

I will try the vitamin C paste on the stains, thanks.

Thanks as always.

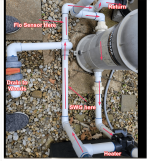

Oh and BTW, my piping is 1.5in not 2in so I think I will need to get some reducer bushings for the SWG.