So the brushes are external to the motor itself... Does this mean that you did nothing to the seal around the motor shaft where it exits the motor box??

So to be more specific about the answer, there are two different flavors of water pump motors - old and new. My motor assembly is from 2016 and

@Apsuhead posted a picture of their Pentair Warrior water pump motor after their motor assembly was replaced under warranty -

Old school (circa 2016) DC Motor -

Newer (circa 2019) DC motor -

You'll notice that the newer design uses a fully enclosed end cap with the brushes inside that. There is also a PCB inside that end cap that has two inductors in series with the power connection to act as high frequency chokes. My guess is the electrical noise from the motor's commutator was probably causing issues on the control board. My control board has some surface mount inductors on it so I wonder if they updated their electrical design. Either way, the brushes can be accessed on the newer motor by simply removing the end cap. Both of those motors of functionally equivalent but I like the newer design as the end cap is better at keeping the carbon dust contained.

As for carbon brushes, these are what I ordered from McMaster-Carr -

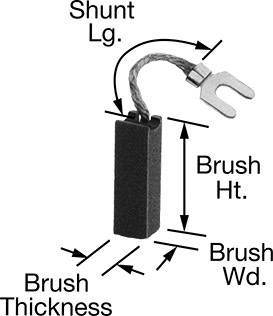

Carbon Brushes with Shunt and Terminal, 1/4" Wide x 13/16" High x 1/4" Thick

However, the 1/4" (~6mm) brushes were kind of big and I had to grind down two sides to make then fit the channel which was more like 4.7mm x 5.7mm . McMaster-Carr also sells 3/16" (4.8mm) brushes and I think those would probably work better or just need minimal shaping. And they cost $6 instead of $9. However, you can look on Amazon and easily find 6mm brushes in like packs of 10 but the only thing is they don't come with the terminal connector crimped on, just the copper wire.

I also assume that you did not do any bearing replacement.

Actually, I did have to replace the rear bearing (see

Post #373 and

Post #419). The rear bearing on my old motor design is somewhat exposed. Water and carbon dust got to it and it was shot - it did not turn smoothly at all. I did soak it in penetrating oil (Liquid Wrench brand) and that cleaned it up a lot as well as made it turn more smoothly but it was still not good. So I went ahead and replaced it. I got the replacement bearing from McMaster-Carr as well. Most bearings are stamped with their Trade Number on them so that they can be easily compared. The rear bearing on my motor was stamped with 626-RS which is equivalent to a 626-2RS.

Permanently Lubricated Stainless Steel Ball Bearing, Sealed, Trade No. 626-2RS, for 6 mm Shaft Diameter

It's designed for a 6mm diameter shaft with a housing that has an ID of 19mm, so the OD of the bearing is approximately 19mm. The bearing is 6mm thick. The one from McMaster cost about $24. You might find them cheaper from other vendors but the one from McMaster is good because it's sealed and permanently lubricated, rated up to 24,000 RPM and can handle high static and dynamic loads. Once I had the new bearing in place, the shaft spun freely in my hand with no detectable resistance.

I did not replace the front bearing or remove the shaft from the brass housing. The front bearing rotated freely with no resistance so I felt it was ok to just clean away all the carbon gunk and pack a bunch of lubricant on it.

The wiring on my motor needed to be cleaned up as well. I showed some earlier pictures of the motor when I pulled it and one of the terminal wires was completely corroded away from the copper shunt wire on the carbon brush. So when I rebuilt the motor, I cleaned up all the wiring and then smeared everything with non-conductive dielectric grease to make sure the wiring would not corrode.