- Jun 8, 2019

- 4,581

- Pool Size

- 20000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Current setup is below. I need to replace the Jandy valve on the suction side. A couple of the screws are stripped out and the plastic loops on the top of the cap where the screws go are broken on several screws. I got a new Jandy valve and am ready to start. I also plan on cutting the skimmer / side drain pipes shorter and lengthening the pipe going up from the pump so it can rest on the ground without a board and bricks.

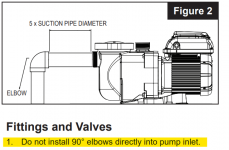

When I run the pump at full speed with one side of the Jandy valve closed I notice some cavitation. To avoid this I’ve had to leave the Jandy valve never fully closing off one side or the other. I’d like to avoid that cavitation if I can. Is there something I can plumb to do so? Would using 2” pipe from the Jandy valve to the pump help, or would it just push the cavitation back to starting earlier?

When I run the pump at full speed with one side of the Jandy valve closed I notice some cavitation. To avoid this I’ve had to leave the Jandy valve never fully closing off one side or the other. I’d like to avoid that cavitation if I can. Is there something I can plumb to do so? Would using 2” pipe from the Jandy valve to the pump help, or would it just push the cavitation back to starting earlier?