About the ORP...

So some people here are interested in ORP work, I am going to write some first conclusions about that:

1. ORP and FC relationship:

It depends on pH and "other multiple factors". On pH I have create a very good relationship between pH and ORP. Seems to be very exact to me in values from .5 and 5 FC ppm, because I have seen that ORP lectures has been variating in function of pH elevation to mantain FC fixed (and with DPD-1 test demostrate fixed FC).

Now about "other factors".

- Cyanuric acid

As some people know, I dont use CYA because I use Bromine tablets in skimmer, and probably I have a "bromide bank" so all bleach (FC) is converted to Bromine.

I have a polycarbonate (double-layer) cover 95% closed or semi-closed that filter most ot UVA rays, so my sanitization loose is very very low. I have tested ORP without any bromine tablets for days and decreasing speed is really really low.

So I can´t experience with CYA, but I have seen people complain about "CYA reduce ORP". I have read ( see

Understanding ORP: Oxidation Reduction Potential ) that ORP is really a better meassure than FC, because it measure not the FC but efectiveness of sanitization. Usually CYA blocks the action of FC, so it is logical than ORP give a lower level: it is talking about effective FC, not total FC.

Morover, CYA is something that has to be very static (exception of water losses and renovations), so influence over ORP should remain constant. If not, means your CYA has changed a lot, so you need to correct it.

- TA. People reported to decrease ORP. I dont have SPAs, jets, waterfalls, and other elements interference the TA, so for me, it is very very stable. Maybe, if the automation system can measure the time all of this is working, could predict how ORP changes to correct it, or better, correct the ORP-FC formuale in function of (pH,estimated TA)

- Other dissolved elements (phosphates, disolved solids, etc.). It is know that same orp probe ph and fc levels give diferent ORP in funcion of water. It is because lots of components, so most people recomend create your proper ORP-FC table.

I dont know, because I can experiment only with my water, but I suspect that all this parameter usually remains

very stable, so can be statically corrected.

It's curious that some articles change the perspective of ORP and FC: If you have low ORP levels with high FC, probably you have bad water (dirt in water), and if you have high ORP levels and low FC, means your water is very pure and healthy.

2. ORP Probe

- I have found that ORP meassurement is very very slow to take correct meassurements. It takes about 25-40 minutes to get adecuate (correct, coherent, and stable) values from a bad state (i.e pump filter off)

- Seems to me that It is slower decreasing than growing.

- When raspberry power down or reboot (the EZO cirtuit loose power, and reboot too), the ORP begin at very low level. I.e if orp is 770, when reboot, it begin rate to 630, and takes 25-40 minutes to get the 770 before.

- I have seen that when pump is in high speed, ORP (and pH) measurements decrease a little (i.e. from 750 to 740), and when change to low speed pump, it goes to previous measurements (750). I dont know why, so is supposed the flow dont affect to probes.

- When the pump starts after some time stopped, I see a small ORP peak. I suspect that ORP grow inside stagnant water (I dont know why).

And more things... I have found that there are two kinds of ORP depending on electrode composition (plata y plantino/calomel), with 50mV of diference.

3. Final Impressions

Although I have been testing for a short time, at the moment I am quite satisfied with the results. I see that the ORP gives very predictable values according to what I am changing in the pool:

- If I remove the bromine tablets, lower the ORP, from a stable value to a lower value, which goes down gradually and slowly.

- When I added bleach for a mini SLAM, I have seen ORP levels very accorndly with expected FC (I have problems here because bromine and chlorine dont have same molecular weight and I dont know how powerfull my bromide-bank is (in DPD-1 you have x2,25 "Cl-Br" relation).

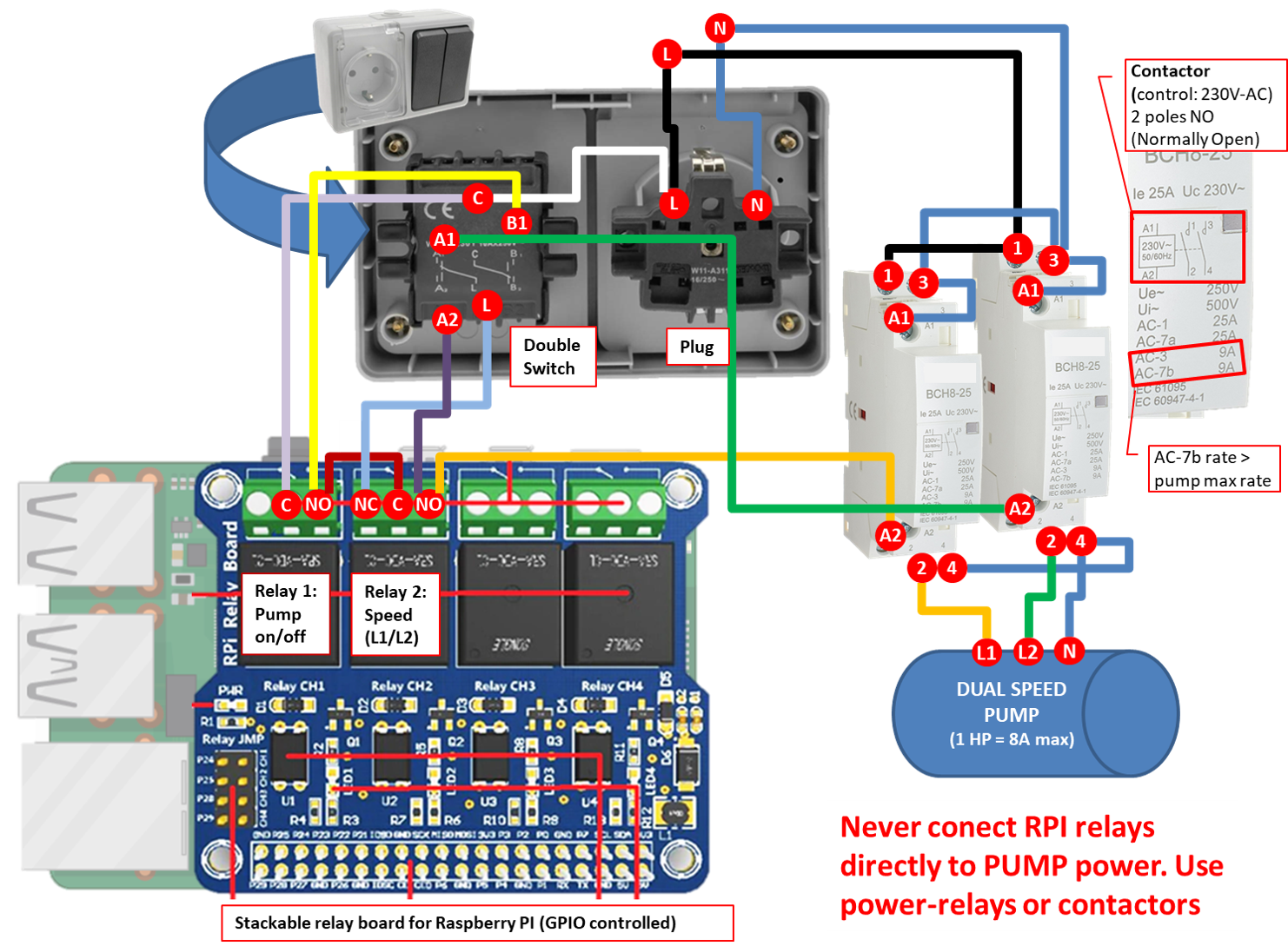

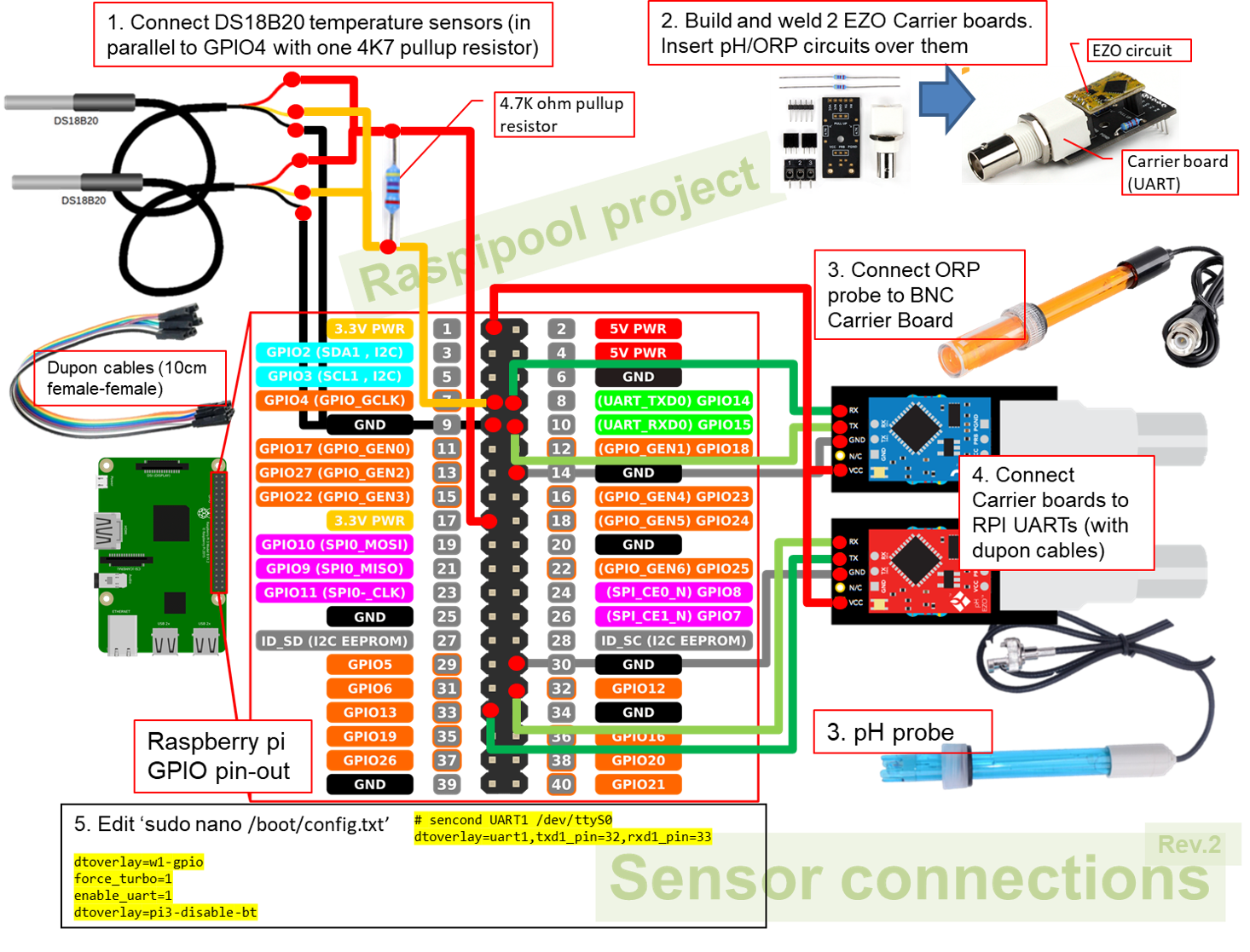

4. Raspipool implementation

I have created a sensor that give the "estimated effective Free Chlorine".

To make the system wide-range kind of pool, I have included 2 methods to calibrate ORP-FC:

1. offset for ORP sensor (like calibration)

2. a more fine tunnig in % (from -100% to +100%) of formulae.

To reach a more accurate meassure (just previous to calculate liquid injections) I have created an automation that set pump at high speed for 8 min, and then low speed for 12 mins, increase the measure interval from 5 min to 20 seconds, and get measure based on medium in last 5 minutes. It sends (configurable) all parameters to notification pushbullet account (FC, ORP, pH, bleach to inject, muriatic to inject).

The calc for bleach injection (once a day) is related to estimated FC (not ORP).

The post seems to be a litle hard, so no more for today...