- Jun 12, 2023

- 124

- Pool Size

- 10000

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- Jandy Aquapure 1400

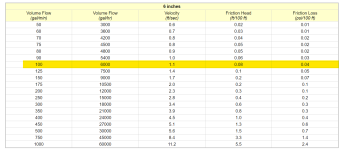

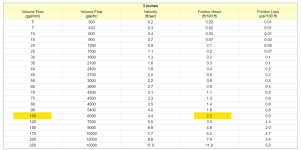

Not super critical. The equipment pad is around the corner and has a fence in front of it. As long as its not screaming its not a big deal.Assuming about 20 feet of head loss, the speed would be about 2,700 RPM to get about 100 GPM.

How much concern is the noise?

2,700 RPM is not horrible, but 2,400 RPM or below is better.

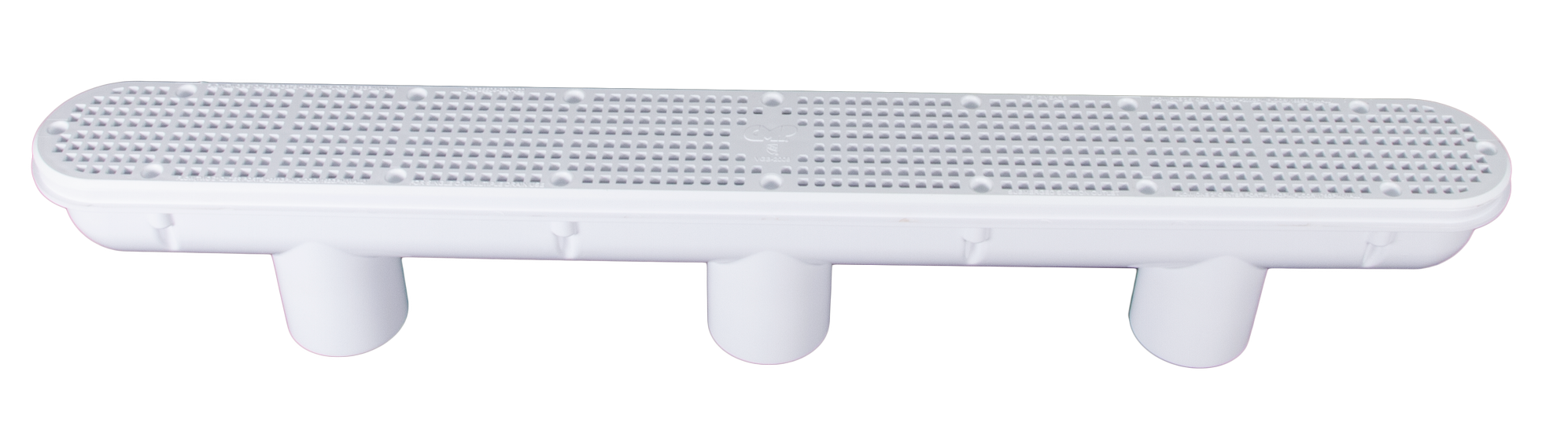

View attachment 521450

I went ahead and ordered it, I like the idea of sticking with a VS pump for now, and this one wasn't too terribly expensive. Once I figure out what actual flow I'll need, I can choose to switch it out for one of the purpose built waterfall pumps if I need to. My pool is still under construction, so its a bit of guess work right now based on what the grotto builder recommends. This one will at least let me go anywhere up to around 120GPM if needed.