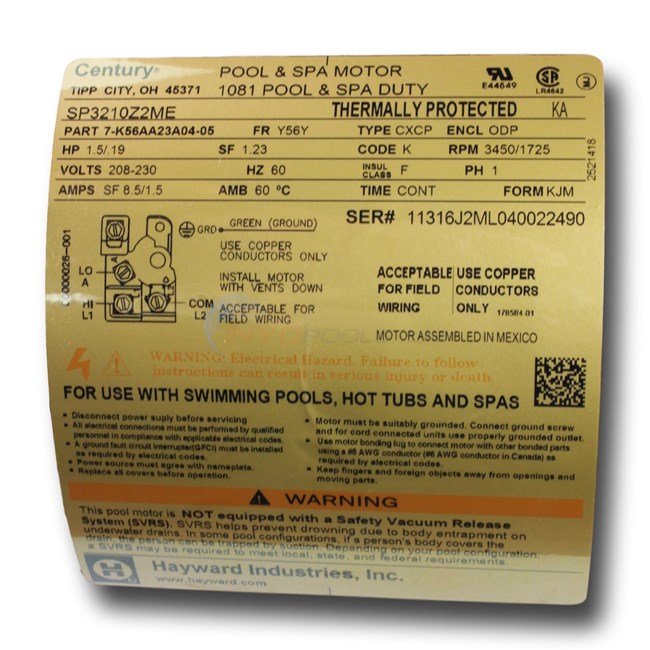

I have an approximate 14k gallon Gunite pool filtered by a Hayward SP3210X152BH Pump driven by a Century 1081 Dual Speed Motor SP3210Z2ME. The pool was installed 3 years ago and everything was working great until Friday morning on July 14th. The pump was found not running, but normally runs in low speed 16 hours a day. The motor is started at high speed of 3 minutes to prime and get pump to speed before switching to low speed.

The problem now is when the motor is started on high speed it only gets about 10 seconds in until it shuts off. I have done all the normal troubleshooting, but the facts are I can hear the thermal protection contact click on the back of the motor and the motor is hot and emits some burning smell. I hooked a clamp on ammeter to the high speed wire and measured a current between 21 and 19.5 amps which it normally runs < 10 amps. I got more of a surprise when I switched it over to the low speed wire and measured 24 amps which it normally runs < 2 amps. I did have to cheat the controller 3 min timer to get the low speed reading by only letting it run high for a few seconds before going to low so that could affect it, but I believe it was up to speed.

For troubleshooting I started by removing both run and start capacitors and testing them with an LC meter. All check out within tolerance and there is no visible bulging or leaking of fluid. I took the motor off the pump housing and removed the diffuser and verified there is nothing clogging the impeller. I cleaned the centrifugal switch on the back of the motor and even took a video of it breaking contact when at speed with my camera to verify it is working right. I also cleaned the main filter for good measure even though the pressure has not changed from its typical 10 psi.

I am not sure what to do at this point. I am afraid the only possibility left might be that the enamel insulation on some of the windings may have melted together resulting in my motor being less of an induction motor and more of a heater at this point.

The problem now is when the motor is started on high speed it only gets about 10 seconds in until it shuts off. I have done all the normal troubleshooting, but the facts are I can hear the thermal protection contact click on the back of the motor and the motor is hot and emits some burning smell. I hooked a clamp on ammeter to the high speed wire and measured a current between 21 and 19.5 amps which it normally runs < 10 amps. I got more of a surprise when I switched it over to the low speed wire and measured 24 amps which it normally runs < 2 amps. I did have to cheat the controller 3 min timer to get the low speed reading by only letting it run high for a few seconds before going to low so that could affect it, but I believe it was up to speed.

For troubleshooting I started by removing both run and start capacitors and testing them with an LC meter. All check out within tolerance and there is no visible bulging or leaking of fluid. I took the motor off the pump housing and removed the diffuser and verified there is nothing clogging the impeller. I cleaned the centrifugal switch on the back of the motor and even took a video of it breaking contact when at speed with my camera to verify it is working right. I also cleaned the main filter for good measure even though the pressure has not changed from its typical 10 psi.

I am not sure what to do at this point. I am afraid the only possibility left might be that the enamel insulation on some of the windings may have melted together resulting in my motor being less of an induction motor and more of a heater at this point.