- Jun 16, 2021

- 661

- Pool Size

- 25500

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Howdy! I've not done a ton of combing thru this forum, so forgive me if these have already been answered elsewhere. I need help and advice sizing and selecting SWG gear. Our PB doesn't recommend them, and they won't install or warranty anything I go out and buy on my own. So not a lot of help or advice from them, plus the previous owner of the house was the client who hired them, so I'm hosed on warranty / business relationship. Even if they did stock the equipment, of course they're not going to be interested in doing such a small job on short notice. So it'll be up to me, which I'm totally fine with. I'm pretty handy with things and know how to be safe with electricity.

I've seen a few threads mentioning oversizing the SWCG is a good idea, and I totally get it. I'm confident our pool is around 25,000 gallons after several different estimates, as well as the recollection of the pool builder, but I can certainly measure more and post here so y'all can check my math. I notice that the Pentair Screen Control app on my phone actually has the SWCG controls enabled, but they don't actually do anything because the hardware isn't present. Knowing that, I'd naturally tend towards their equipment, just for convenience and consistency's sake. That seems to limit my search to the IntelliChlor and iChlor lines. If the model numbers mean anything, does that tell me that the iChlor 30 would be for a 30k pool and "just barely enough" with a 1.2x overage margin? I found the correct manual that actually shows the IC series pool volumes. In overage margin, IC40 would be 1.6x and IC60 would be 2.4x then?

...

Did I just answer my own question? Is the IntelliChlor IC60 the correct unit for my needs? If so, what all do I need in peripherals besides the PC100 (P/N 520556) power supply kit and whatever plumbing unions make it fit? I had a thought it could be a drop-in replacement for my Rainbow 320 tab-soaker.

Thanks in advance!

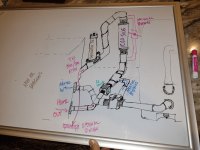

edit: forgot photo.

I've seen a few threads mentioning oversizing the SWCG is a good idea, and I totally get it. I'm confident our pool is around 25,000 gallons after several different estimates, as well as the recollection of the pool builder, but I can certainly measure more and post here so y'all can check my math. I notice that the Pentair Screen Control app on my phone actually has the SWCG controls enabled, but they don't actually do anything because the hardware isn't present. Knowing that, I'd naturally tend towards their equipment, just for convenience and consistency's sake. That seems to limit my search to the IntelliChlor and iChlor lines. If the model numbers mean anything, does that tell me that the iChlor 30 would be for a 30k pool and "just barely enough" with a 1.2x overage margin? I found the correct manual that actually shows the IC series pool volumes. In overage margin, IC40 would be 1.6x and IC60 would be 2.4x then?

...

Did I just answer my own question? Is the IntelliChlor IC60 the correct unit for my needs? If so, what all do I need in peripherals besides the PC100 (P/N 520556) power supply kit and whatever plumbing unions make it fit? I had a thought it could be a drop-in replacement for my Rainbow 320 tab-soaker.

Thanks in advance!

edit: forgot photo.