- Jul 6, 2021

- 204

- Pool Size

- 40000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Plumbing is done, and I went to do a pressure test and it's not holding pressure. It's basically my worst fears come to pass! I tightened up all the threaded joints, and was hoping that would be what it was, but I'm still losing pressure very quickly. Only takes a few minutes to go from 15psi to 0. This is going to be a pain to try and find the leak - any suggestions would be helpful. I'm going to start spraying all the joints with soapy water, and I'm seriously considering adding some valves on each line to at least isolate it down.

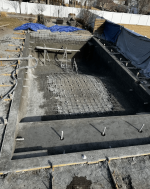

Here's what I made to do the pressure test:

Here's what I made to do the pressure test: