- May 3, 2007

- 18,074

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

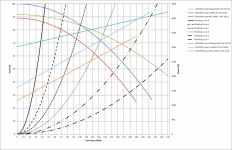

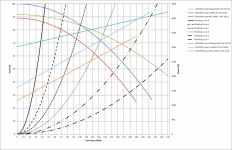

I did a few head loss calculations and here is what I came up with.

Feature Recommendations:

6' Sheer - 90 GPM

3x1' Sheers - 45 GPM

1 Bubbler - 40 GPM

6 Jets - 30 GPM

Total Recommended Flow Rate: 205 GPM

Assumptions:

3" 45' Suction + 5 90s

1 Cartridge Filter

4 x (2.5" 45' Lines + 5 90s)

Feature head loss based upon documentation and flow rate balance to each element

Combined Plumbing curve = 0.002 (Curve E below)

Operating points:

WhisperfloXF: 181 GPM @ 65' of head

IntellifloXF: 167 GPM @ 56' of head

Intelliflo3: 154 GPM @ 47' of head

Technically, none of the pumps will provide the maximum flow rate recommended so you might be better off with two pumps. One for the sheers and one for the rest. This might be a better solution since shutting off one feature will require rebalancing the rest of the features for proper flow rate. Using a single pump for multiple features of differing head loss can be a challenge for balancing the flow rates as features are turned on and off.

Another option would be to use two very small pump's below DOE regulations, one for the bubbler and one for the deck jets. A 1/2 HP pump would probably be sufficient for those applications.

Feature Recommendations:

6' Sheer - 90 GPM

3x1' Sheers - 45 GPM

1 Bubbler - 40 GPM

6 Jets - 30 GPM

Total Recommended Flow Rate: 205 GPM

Assumptions:

3" 45' Suction + 5 90s

1 Cartridge Filter

4 x (2.5" 45' Lines + 5 90s)

Feature head loss based upon documentation and flow rate balance to each element

Combined Plumbing curve = 0.002 (Curve E below)

Operating points:

WhisperfloXF: 181 GPM @ 65' of head

IntellifloXF: 167 GPM @ 56' of head

Intelliflo3: 154 GPM @ 47' of head

Technically, none of the pumps will provide the maximum flow rate recommended so you might be better off with two pumps. One for the sheers and one for the rest. This might be a better solution since shutting off one feature will require rebalancing the rest of the features for proper flow rate. Using a single pump for multiple features of differing head loss can be a challenge for balancing the flow rates as features are turned on and off.

Another option would be to use two very small pump's below DOE regulations, one for the bubbler and one for the deck jets. A 1/2 HP pump would probably be sufficient for those applications.