Pentair does make a Bypass check valve, but the spring is 12 lb, which is way too much.

39.....R172305 WATER BYPASS CHECK VALVE

The Pentair Ultratemp heat pump uses the 12 lb. spring bypass, but the pressure never gets to 12 psi, so I don't see where it would ever do anything.

From the chart, 9 psi is the highest pressure.

You can get the 12 lb bypass, but it seems to me that it won't help.

Maybe check with Pentair and ask them what spring strength should be used if you were going to do a spring bypass on the Mastertemp.

You don't have to do a spring bypass on the Mastertemp as the flow will not exceed 120 GPM as specified in the manual.

However, in my opinion, putting anything over 60 GPM is unnecessary and it can create extra wear on the heater components.

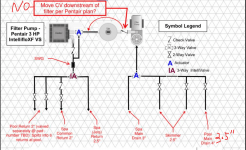

Below is the MasterTemp internal bypass that all of the water need to flow through when the heater is not on.

When the heater is on, part of the water flow goes through the bypass and part goes through the heat exchanger, which has a thermal regulator at the exit.

So, you're trying to push 120 GPM through a relatively small internal bypass, which is a spring bypass, and a small thermal regulator.

The extra bypass relieves the heater's internal bypass from excessive flow.